Method for recovering chlorine-containing volatile organic compounds in organic waste gas by using ionic liquid

A volatile organic compound, ionic liquid technology, applied in separation methods, chemical instruments and methods, gas treatment, etc., can solve the problems of low operating energy consumption, low absorption capacity, waste water generation, etc., and achieve low energy consumption and efficient recovery. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

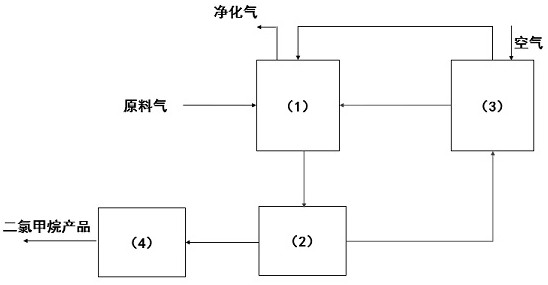

Image

Examples

Embodiment 1

[0025] The gas volume is 7000m 3 / h, the dichloromethane content is 10%, and the chlorine-containing organic waste gas with a temperature of 45° C. is passed into the bottom of the multi-stage absorption tower 1, and is countercurrently contacted with the absorbent from the upper part of the multi-stage absorption tower 1 to absorb the dichloromethane, wherein The operating temperature of the multistage absorption tower 1 is 25°C, the operating pressure is normal pressure, and the number of theoretical plates is 25. The ionic liquid 1-butylpiperidine acetate is used as the absorbent, and the flow rate of the absorbent is 90000kg / h. After being treated in the multistage absorption tower 1, the dichloromethane content in the purified gas at the top of the tower is less than 20ppm.

[0026] The content of dichloromethane at the bottom of the multi-stage absorption tower 1 is 14%, and the ionic liquid rich liquid at a temperature of 90°C is heated to 100°C by the rich liquid heate...

Embodiment 2

[0030] The gas volume is 8000m 3 / h, the content of methyl chloroacetate is 0.73%, the content of chloroform is 0.66%, and the chlorine-containing organic waste gas with a temperature of 30 ° C is passed into the bottom of the multi-stage absorption tower 1, and is contacted with the absorbent from the upper part of the multi-stage absorption tower 1 for countercurrent contact. The absorption of chloroform and methyl chloroacetate, wherein the operating temperature of the multi-stage absorption tower 1 is 5 ℃, the operating pressure is normal pressure, the number of theoretical plates is 15, and the absorbent is 1-ethylpyridinesulfate ethyl ester ionic liquid, after many After the treatment in stage absorption tower 1, the contents of methyl chloroacetate and chloroform in the purified gas at the top of the tower are both less than 30ppm.

[0031] The content of methyl chloroacetate at the bottom of the multi-stage absorption tower 1 is 2.50%, the content of chloroform is 1.60...

Embodiment 3

[0035] The gas volume is 8000m 3 / h, the ethyl chloride content is 3%, and the chlorine-containing organic waste gas with a temperature of 45° C. is passed into the bottom of the multi-stage absorption tower 1, and is countercurrently contacted with the absorbent from the upper part of the multi-stage absorption tower 1 to absorb ethyl chloride, wherein The operating temperature of the multi-stage absorption tower 1 is 30°C, the operating pressure is normal pressure, the number of theoretical plates is 20, the absorbent is ethyl morpholine propionate ionic liquid, the flow rate of the absorbent is 80000kg / h, after multi-stage absorption After the treatment in tower 1, the content of ethyl chloride in the purified gas at the top of the tower is less than 20ppm.

[0036] The content of ethyl chloride at the bottom of the multi-stage absorption tower 1 is 14%, and the ionic liquid rich liquid at a temperature of 90°C is heated to 105°C by the rich liquid heater, and then enters t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com