Method for improving banded structure of hot-formed steel plate

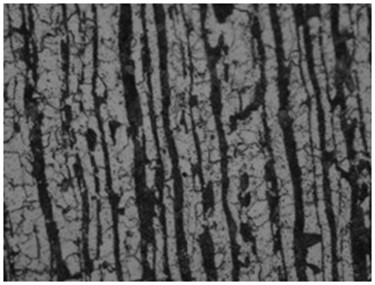

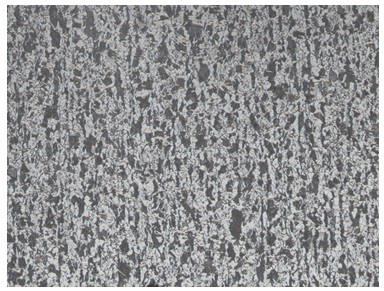

A strip-shaped structure, hot-formed steel technology, applied in the field of iron and steel metallurgy and rolling, can solve the problems of uneven hardness distribution of steel plates, poor bending and other properties, and uneven structure, so as to reduce the probability of strip-shaped structure defects. , Improve the effect of performance improvement such as band structure, fatigue and welding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] The chemical composition and mass percentage of the hot stamping steel in this example are: C: 0.20%, Mn: 1.5%, Si: 0.15%, S: 0.005%, P: 0.022%, Al: 0.030%, RE: 0.1%, Ti: 0.03%, Cr: 0.40%, B: 0.005%, and the balance is iron and unavoidable impurities.

[0031] The production process of hot stamping formed steel in this embodiment includes hot metal desulfurization pretreatment, converter molten steel smelting, LF furnace molten steel refining treatment, continuous casting, hot continuous rolling, pickling and cold continuous rolling, and continuous annealing processes. in:

[0032] (1) Desulfurization pretreatment of molten iron: the S content of the outbound station is 0.008%.

[0033] (2) Converter molten steel smelting: the calming time is 150s; converter tapping uses slag detection and sliding plate slag blocking technology to control the converter molten steel slag < 2kg / t; start to add ferromanganese, ferrosilicon, Aluminum is alloyed and deoxidized.

[0034] (...

Embodiment 2

[0041] The mass fractions of the chemical components of the hot stamping steel in this example are: C: 0.45%, Mn: 1.0%, Si: 0.35%, S: 0.004%, P: 0.015%, Al: 0.050%, RE: 0.05%, Ti: 0.01%, Cr: 0.50%, B: 0.001%, and the balance is iron and unavoidable impurities.

[0042] The production process of hot stamping formed steel in this embodiment includes hot metal desulfurization pretreatment, converter molten steel smelting, LF furnace molten steel refining treatment, continuous casting, hot continuous rolling, pickling and cold continuous rolling, and continuous annealing. in:

[0043] (1) Desulfurization pretreatment of molten iron: the S content of the outbound station is 0.010%.

[0044] (2) Converter molten steel smelting: the calming time is 140s; converter tapping adopts slag detection and sliding plate slag blocking technology to control the converter molten steel slag < 2kg / t; start to add ferromanganese, ferrosilicon, Aluminum is alloyed and deoxidized.

[0045] (3) Refin...

Embodiment 3

[0052] The mass fractions of the chemical components of the hot stamping steel in this example are: C: 0.23%, Mn: 1.2%, Si: 0.25%, S: 0.003%, P: 0.017%, Al: 0.040%, RE: 0.01%, Ti: 0.06%, Cr: 0.40%, B: 0.003%, and the balance is iron and unavoidable impurities.

[0053] The production process of hot stamping formed steel in this embodiment includes hot metal desulfurization pretreatment, converter molten steel smelting, LF furnace molten steel refining treatment, continuous casting, hot continuous rolling, pickling and cold continuous rolling, and continuous annealing. in:

[0054] (1) Desulfurization pretreatment of molten iron: the S content of the outbound station is 0.007%.

[0055] (2) Converter molten steel smelting: the calming time is 160s; converter tapping uses slag detection and sliding plate slag blocking technology to control the converter molten steel slag < 2kg / t; start to add ferromanganese, ferrosilicon, Aluminum is alloyed and deoxidized.

[0056] (3) Refin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com