Quantum dot composite material, preparation method thereof and quantum dot light-emitting device

A quantum dot material and quantum dot light-emitting technology, which are applied in the field of quantum dot composite materials and their preparation, and quantum dot light-emitting devices, and can solve the problems of insufficient combination of quantum dot materials and organic gels, and unsatisfactory elasticity and toughness of light-emitting materials. , to achieve the effects of strong tensile properties and mechanical properties, enhanced bonding stability, and enhanced dispersion properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

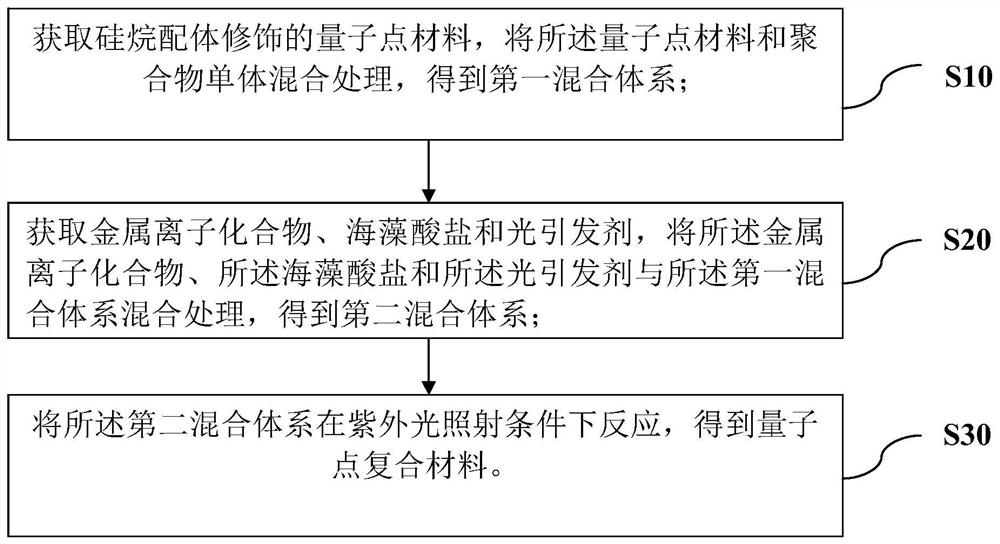

[0028] Such as figure 1 As shown, the embodiment of the present invention provides a method for preparing a quantum dot composite material, comprising the following steps:

[0029] S10. Obtain a silane ligand-modified quantum dot material, and mix the quantum dot material with a polymer monomer to obtain a first mixed system;

[0030] S20. Obtain a metal ion compound, an alginate, and a photoinitiator, and mix the metal ion compound, the alginate, and the photoinitiator with the first mixed system to obtain a second mixed system;

[0031] S30. Reacting the second mixed system under ultraviolet light irradiation conditions to obtain a quantum dot composite material.

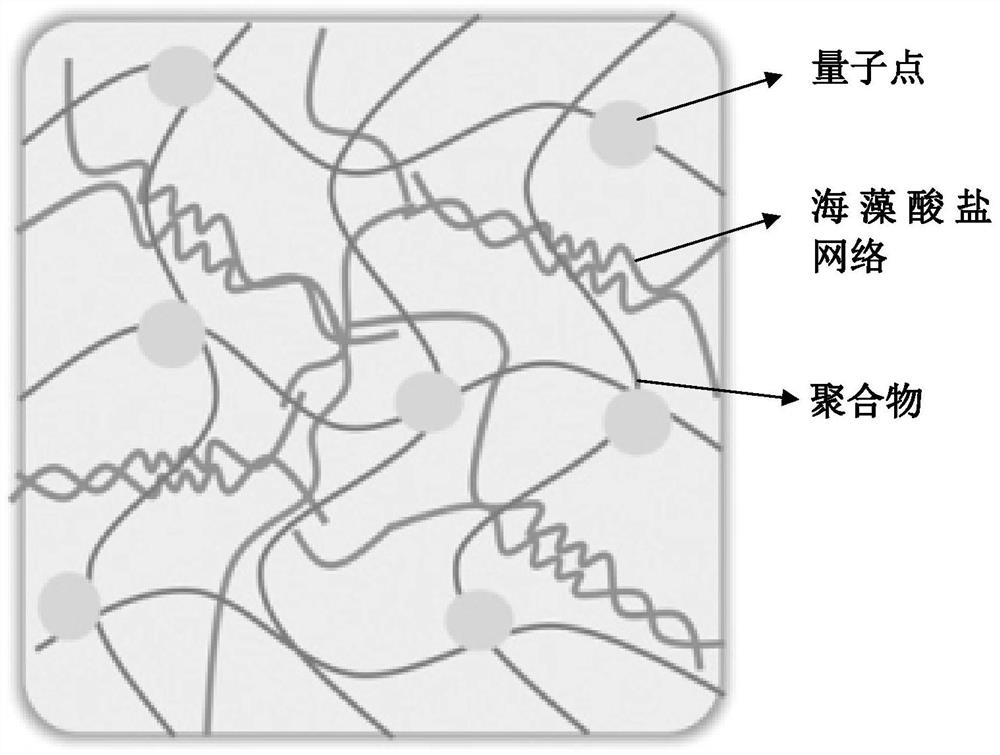

[0032]The preparation method of the quantum dot composite material provided by the embodiment of the present invention, first, obtain the quantum dot material modified by the silane ligand, the quantum dot material modified by the silane ligand not only enhances the dispersion performance of the quantum dot mater...

Embodiment 1

[0079] A CdSe quantum dot composite material of double network structure alginic acid / PAAM, the preparation steps comprising:

[0080]1. Disperse 6 mg of CdSe in 10 mL of deionized water, sonicate for 25 minutes, then add 6 mL of vinyltrimethoxysilane, mix well, continue stirring at 70 ° C for 2 hours, wash and dry to obtain vinyltrimethoxysilane-modified CdSe quantum dots ;

[0081] 2. Add Ca 2+ Dissolve with EDTA in 10mL deionized water to make a concentration of 30mmol / L to obtain Ca 2+ - EDTA precursor;

[0082] 3. Dissolve 2 mg of vinyltrimethoxysilane-modified CdSe quantum dots, sodium alginate and acrylamide in the above Ca 2+ -In the EDTA precursor solution, the concentrations of sodium alginate and acrylamide are 1wt / vol% and 3mol / L respectively, after mixing evenly, add 4μL of 2-hydroxy-2-methyl-1-phenylacetone, and stir for 25min, Obtain reaction precursor solution;

[0083] 4. Pour the reaction precursor solution into a petri dish, irradiate with ultraviolet l...

Embodiment 2

[0085] A kind of CdSe with double network structure alginic acid / PEN 1-x S x / CdSe y S 1-y / CdS quantum dot composite material, the preparation steps include:

[0086] 1. Mix 8mg CdSe 1-x S x / CdSe y S 1-y / CdS was dispersed in 10mL of deionized water, ultrasonicated for 30min, then 8mL of vinyltrimethoxysilane was added, after mixing evenly, the stirring was continued at 65°C for 3h, after cleaning, drying was performed to obtain vinyltrimethoxysilane-modified quantum dots;

[0087] 2. Mg 2+ Dissolve EDTA in 10mL of deionized water to make a concentration of 35mmol / L to obtain Mg 2+ with EDTA precursor;

[0088] 3. Dissolve 3 mg of vinyltrimethoxysilane-modified quantum dots, sodium alginate and ethylene naphthalate in the above Mg 2+ -In the EDTA precursor solution, the concentrations of sodium alginate and ethylene naphthalate are 3wt / vol% and 5mol / L respectively, after mixing evenly, add 7μL 2,4,6-trimethylbenzoyl- Diphenylphosphine oxide was stirred for 20 minu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com