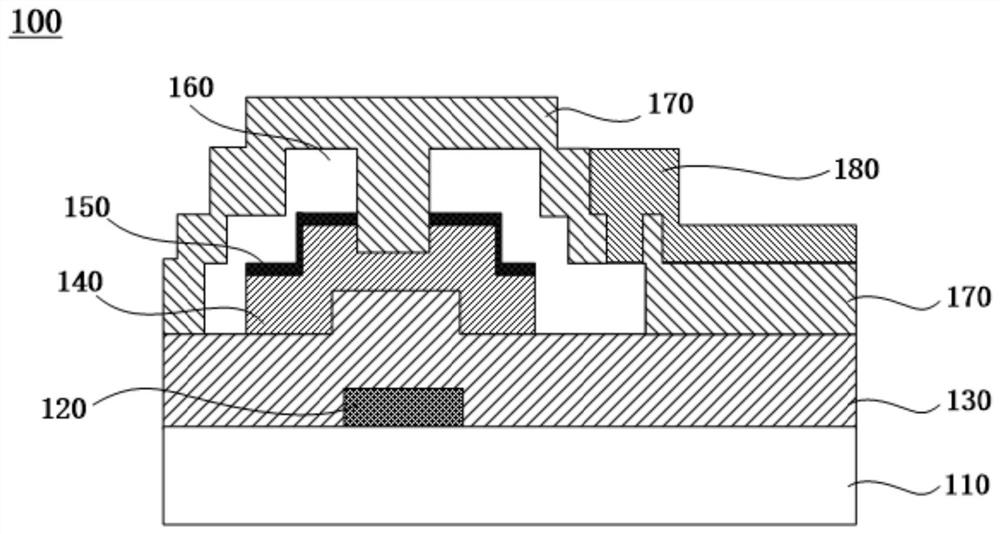

Copper-molybdenum metal etching solution and application thereof

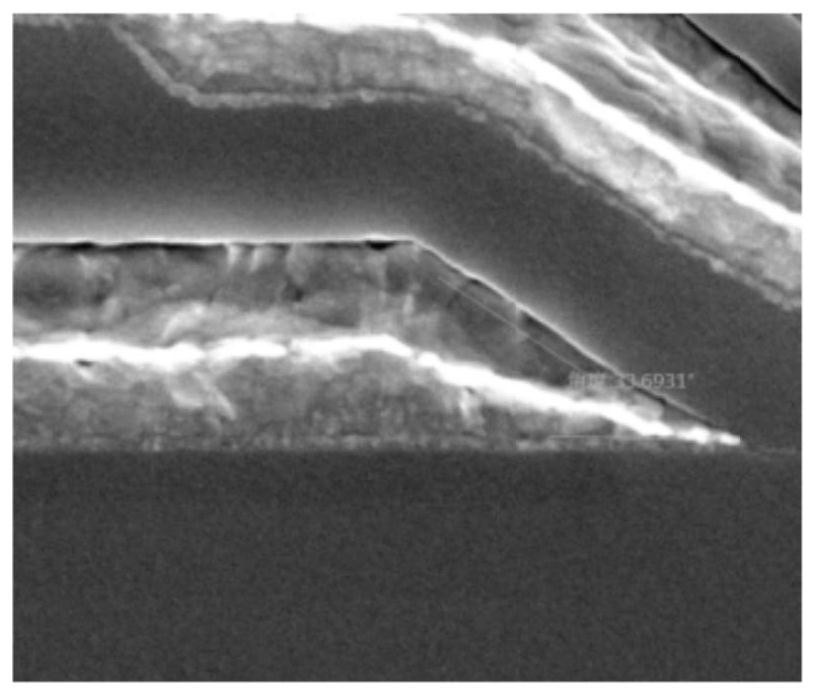

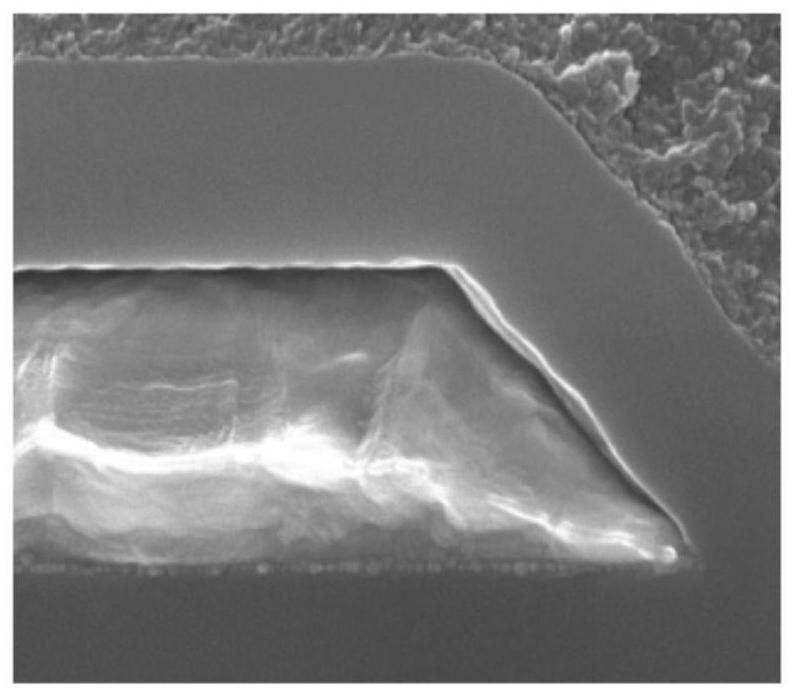

A metal etching, copper-molybdenum technology, applied in the field of copper-molybdenum metal etching solution, can solve the problems of etching rate difference, copper hollowing corrosion, etc., to avoid copper hollowing, reduce wastewater treatment costs, and solve copper metal layer hollowing corrosion Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] This embodiment provides a copper molybdenum metal etching solution, the composition of the copper molybdenum metal etching solution includes: 1wt% hydrogen peroxide, 10wt% shape control agent, 0.01wt% etching stabilizer, 13wt% % of chelating agent, 0.01wt% of pH regulator and 2.39wt% of etching additive, and the balance of deionized water.

[0052] The shape control agent is selected from furan and 5-aminotetrazole.

[0053] The etching stabilizer is selected from monoammonium phosphate and diammonium phosphate.

[0054] Described chelating agent selects iminoacetic acid for use.

[0055] The etching additive is selected from acetic acid.

[0056] The pH value of the copper-molybdenum metal etching solution is 4. Described pH adjusting agent selects potassium carbonate for use.

[0057] The etching temperature of the copper-molybdenum metal etching solution is 28°C.

Embodiment 2

[0059] This embodiment provides a copper molybdenum metal etching solution, the composition of the copper molybdenum metal etching solution includes: 21wt% hydrogen peroxide, 0.01wt% shape control agent, 5wt% etching stabilizer, 1wt% % of chelating agent, 8wt% of pH regulator and 0.01wt% of etching additive, and the balance of deionized water.

[0060] The shape control agent is selected from pyrrolidone and hydroxymethylbenzotriazole.

[0061] Described etching stabilizer selects sodium hydrogen phosphate, potassium hydrogen phosphate for use.

[0062] Described chelating agent selects nitrilotriacetic acid for use.

[0063] The etching additive is selected from butyric acid.

[0064] The pH value of the copper-molybdenum metal etching solution is 5. Described pH adjusting agent selects sodium hydroxide for use.

[0065] The etching temperature of the copper-molybdenum metal etching solution is 35°C.

Embodiment 3

[0067] This embodiment provides a copper molybdenum metal etching solution, the composition of the copper molybdenum metal etching solution includes: 6wt% hydrogen peroxide, 8wt% shape control agent, 0.5wt% etching stabilizer, 6wt% % of chelating agent, 0.5wt% of pH regulator and 1.8wt% of etching additive, and the balance of deionized water.

[0068] The shape control agent is selected from hydroxymethylbenzotriazole.

[0069] The etch stabilizer is selected from monoammonium phosphate.

[0070] Described chelating agent selects sarcosine for use.

[0071] The etching additive is selected from formic acid.

[0072] The pH value of the copper-molybdenum metal etching solution is 4.5. Described pH regulator selects sodium carbonate, sodium hydroxide for use.

[0073] The etching temperature of the copper-molybdenum metal etching solution is 30°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com