A kind of etchant for silicon-based multilayer film

A multi-layer film and etching solution technology, applied in the direction of surface etching composition, chemical instruments and methods, etc., can solve the problem that it is difficult to meet the processing requirements of thin film transistors, and the etching speed of the silicon nitride layer and the silicon oxide layer cannot be basically the same etc. to achieve the effect of improving wettability and etching uniformity, fast etching speed and smooth etching surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

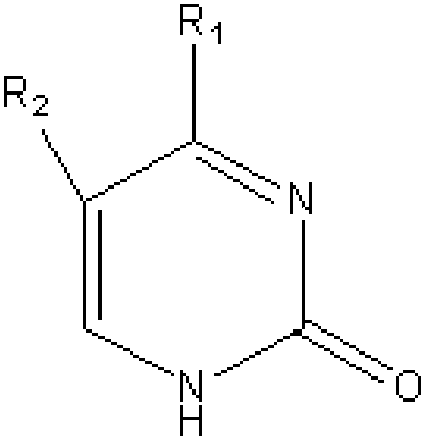

Image

Examples

Embodiment 1

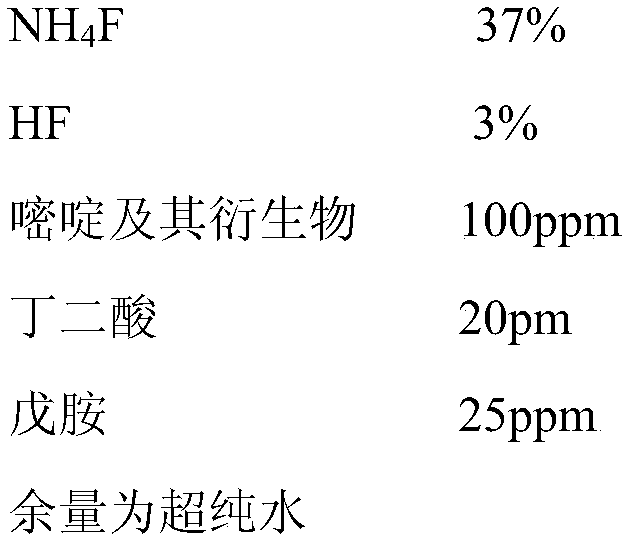

[0029] The components and mass percentages of the etchant for silicon-based multilayer films are:

[0030]

[0031] Pyrimidine and its derivatives are cytosine, and the resistivity of the ultrapure water at 25°C is not less than 18 megohms.

Embodiment 2

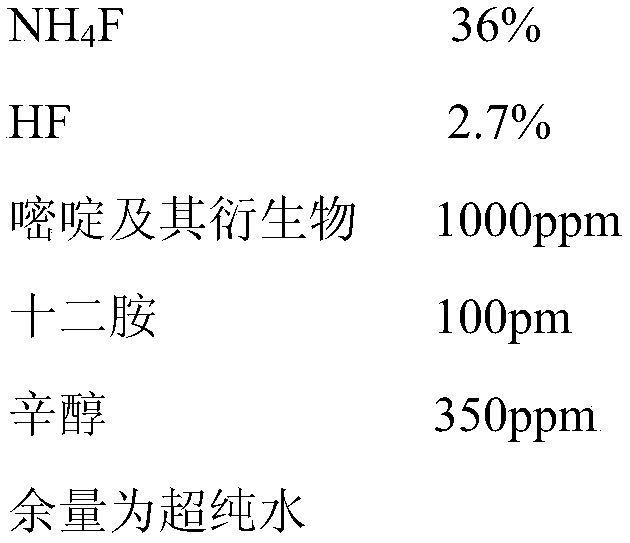

[0033] The components and mass percentages of the etchant for silicon-based multilayer films are:

[0034]

[0035] Pyrimidine and its derivatives are uracil, and the resistivity of the ultrapure water at 25°C is not less than 18 megohms.

Embodiment 3

[0037] The components and mass percentages of the etchant for silicon-based multilayer films are:

[0038]

[0039]

[0040] The pyrimidine and its derivatives are 5-fluorocytosine, and the resistivity of the ultrapure water at 25° C. is not lower than 18 megohms.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com