Wafer wet etching equipment

A wet etching, wafer technology, used in electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve problems such as large differences in etching rates in different chambers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The wafer wet etching equipment structure of specific embodiment of the present invention sees figure 1 .

[0029] figure 1 Among them, NV is the needle valve (Needle Valve); AV is the air valve (Air Valve); TC is the temperature controller (Temperature Controller); FM is the flow meter (Flow meter).

[0030] The wafer wet etching equipment includes an etchant, which is placed in a storage container 1, and the usual storage capacity is 40L. In this embodiment, the etchant is TMAH tetramethylammonium hydroxide.

[0031] The pipelines connected with the storage container 1 include a main pipeline 5 , a pressure relief pipeline 14 , an auxiliary pipeline 15 and a recovery pipeline 3 . The main pipeline 5 includes a pump 2, a heater 4, a flow meter, a temperature controller and the like. The pressure relief pipeline 14 includes a pressure sensor, a pressure regulator and the like.

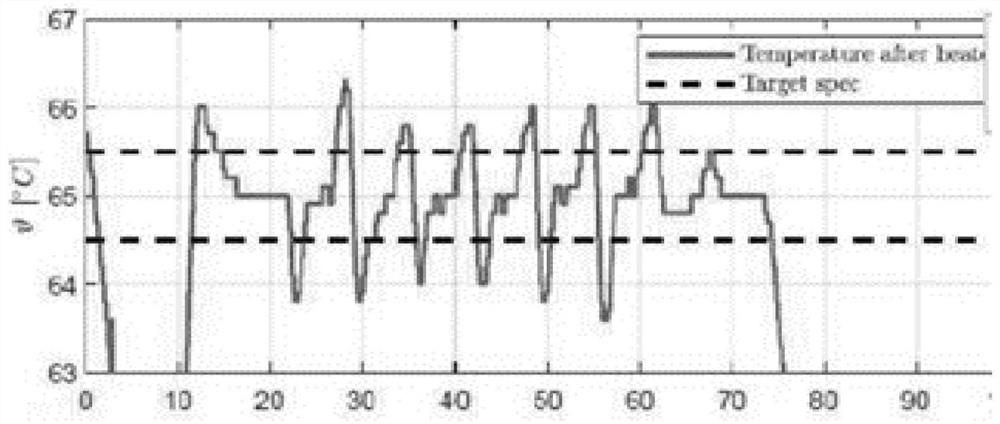

[0032] The heater 4 is used to control the temperature of the etchant on the main pipeli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com