Preparation method of nano rare earth hexaboride

A technology of hexaboride and nano-rare earth, which is applied in the field of preparation of nano-rare earth hexaboride, can solve the problems of high requirements for preparation equipment, long production cycle, poor powder performance, etc., and achieves low requirements for equipment, simple preparation process, and ease of use. effect of industrialization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

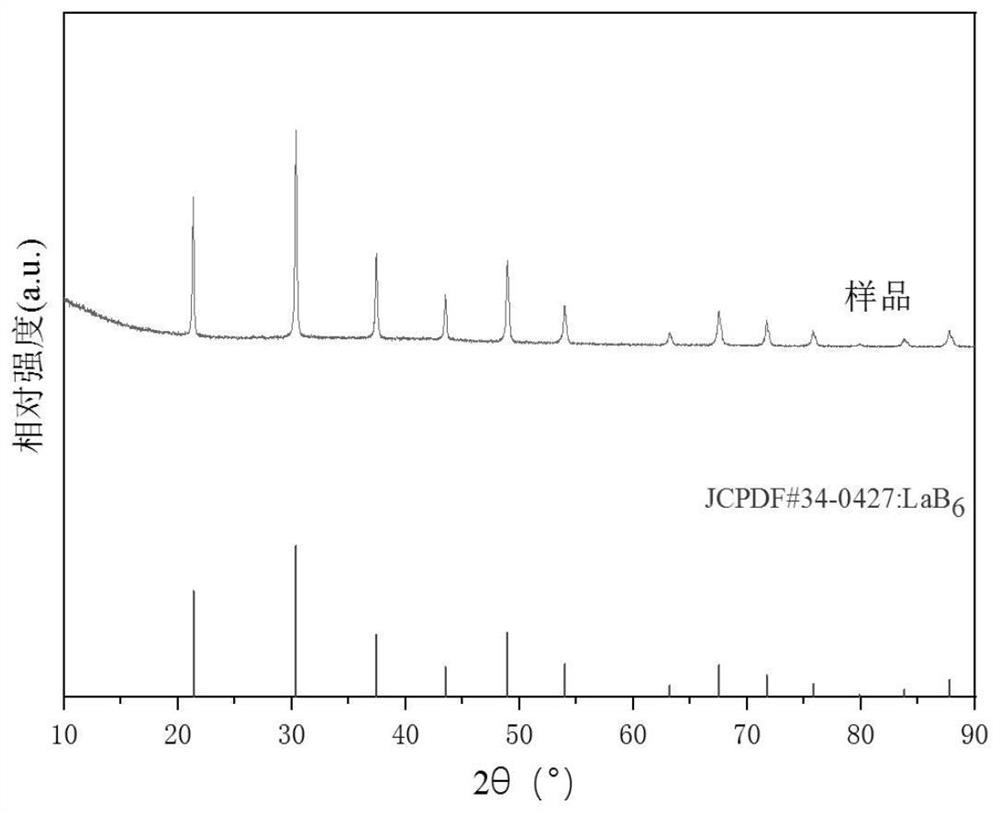

[0033]Weigh 10.625g of lanthanum nitrate hexahydrate, 1.84g of glycine and 1.592g of boron powder in sequence, grind and mix them thoroughly in a mortar, put them into a corundum crucible, put them in a muffle furnace, raise the temperature to 320°C to ignite the reactants, and burn After completion, the product was taken out, washed successively with dilute hydrochloric acid, dilute sulfuric acid and pure water, and dried to obtain a sample.

example 2

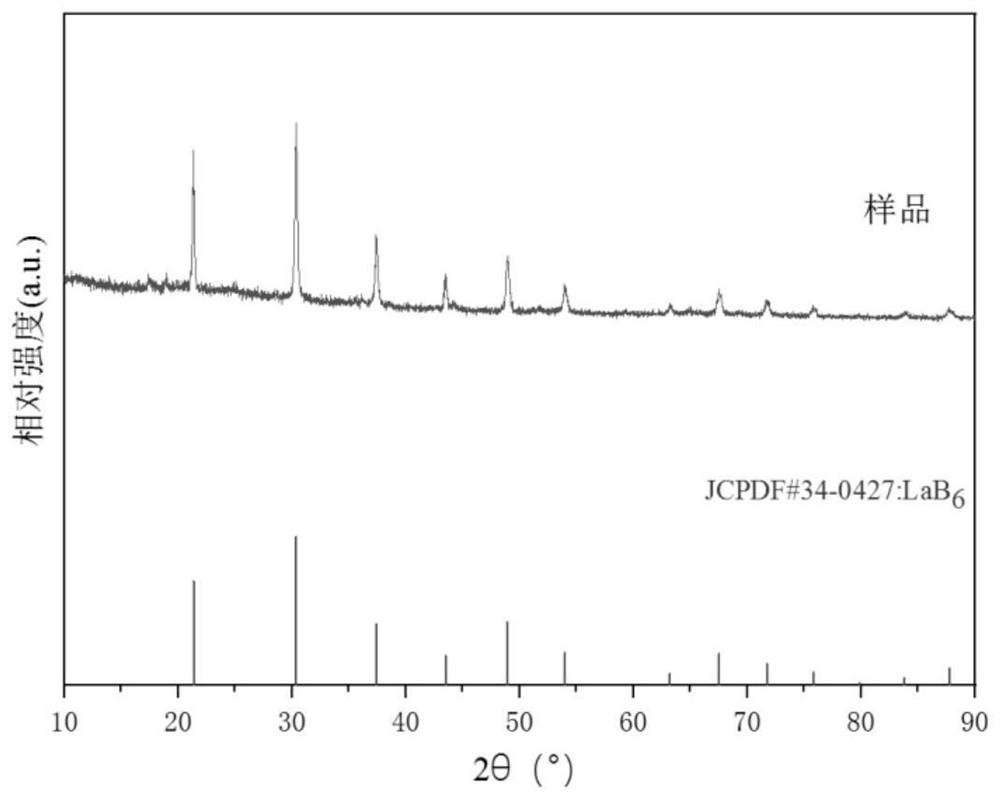

[0035] Weigh 10.635g of lanthanum nitrate hexahydrate and 1.84g of glycine. Mix in a quartz beaker and add enough water to dissolve completely. Then add 1.592g of boron powder, stir evenly, heat and concentrate until viscous, put it into a muffle furnace, and raise the temperature to 320°C to ignite the reactants. After the combustion is completed, the product is taken out, washed with dilute hydrochloric acid, dilute sulfuric acid and pure water in turn, and after drying, the sample is obtained

Embodiment 1

[0037] Weigh 1.629g of lanthanum oxide, add an appropriate amount of nitric acid into a quartz beaker, heat and dissolve, and prepare a lanthanum nitrate solution, add 0.584g of sodium chloride and 0.75g of glycine in turn, heat to dissolve completely, then add 0.649g of boron powder, and stir evenly , heat and condense to a viscous shape, put it into a muffle furnace, raise the temperature to 320°C to ignite the reactants, take out the product after the combustion is complete, wash with dilute hydrochloric acid, dilute sulfuric acid and pure water in sequence, and dry to obtain the sample.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com