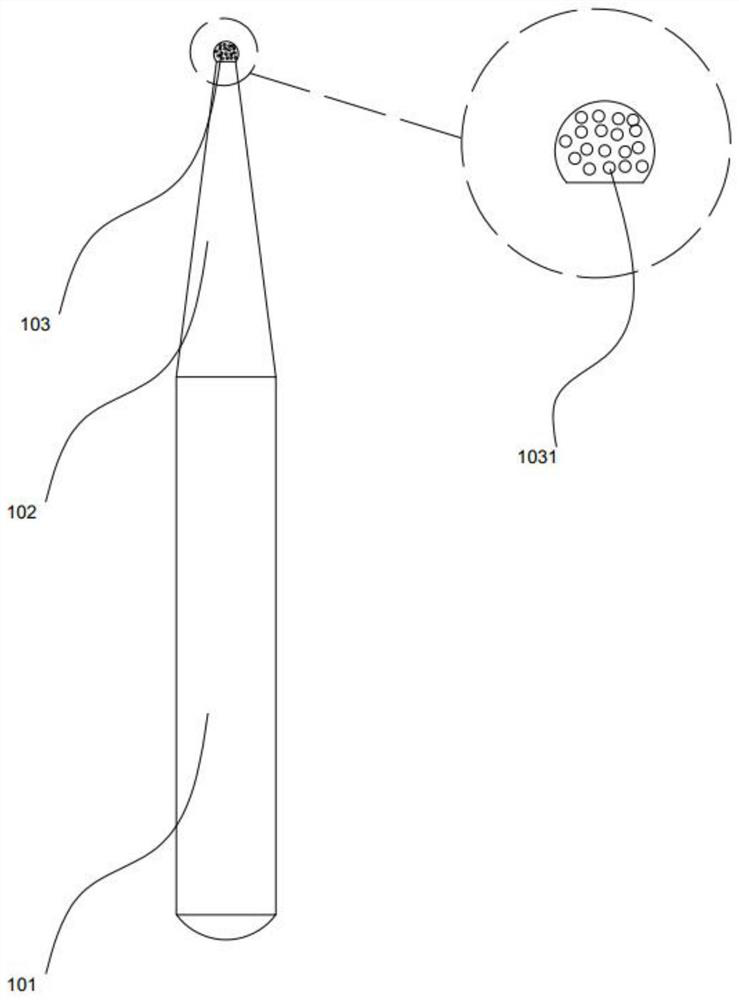

Dental bur

A kind of bur and dental technology, applied in dentistry, dental prosthesis, dental tools, etc., can solve the problems of not being able to effectively meet high speed, weak structural stability, complex process, etc., to improve practicability and service life, and improve combination performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Its raw material of the solder of the brazing layer of the dental bur in the present embodiment comprises, by mass fraction, 45 parts of copper, 9 parts of silver, 30 parts of zinc, 2.8 parts of nickel, and particle diameter is 0.5 parts of graphene powder material of 80 microns. parts, 0.2 parts of magnesium carbonate, and 0.95 parts of rosin.

[0022] The preparation method includes: light material treatment: spread the graphene oxide powder in the reaction chamber, and after vacuuming to 5Pa, feed a mixed gas of methane and Ar gas, wherein the volume ratio of methane is 5%, and the volume ratio of methane is controlled. The flow rate is 40sccm, the mixed gas pressure is adjusted to 100Pa, and then the working temperature is raised to 600°C. After reaching the working temperature, the RF power is turned on, and the RF power is adjusted to 150W. After processing for 17 minutes, cool with the furnace, and then mix with magnesium carbonate powder and rosin powder Finally...

Embodiment 2

[0026] Its raw material of the solder of the brazing layer of the dental bur in the present embodiment comprises, by mass fraction, 55 parts of copper, 12 parts of silver, 25 parts of zinc, 2.3 parts of nickel, and particle diameter is the graphene powder material 1 of 200 microns Parts, 0.28 parts of magnesium carbonate, 0.85 parts of rosin.

[0027] The preparation method includes: light material treatment: spread the graphene oxide powder in the reaction chamber, and after evacuating to 5Pa, feed a mixed gas of methane and Ar gas, wherein the volume ratio of methane is 10%, and control the volume ratio of methane The flow rate is 30sccm, the mixed gas pressure is adjusted to 500Pa, and then the working temperature is raised to 700°C. After reaching the working temperature, the RF power is turned on, and the RF power is adjusted to 160W. After processing for 15 minutes, it is cooled with the furnace, and then mixed with magnesium carbonate powder and rosin powder Finally, it...

Embodiment 3

[0031] Its raw material of the solder of the brazing layer of the dental bur in the present embodiment comprises, by mass fraction, 50 parts of copper, 8 parts of silver, 40 parts of zinc, 2.5 parts of nickel, and particle diameter is the graphene powder material 0.7 of 100 microns. part, 0.3 part of magnesium carbonate, and 0.9 part of rosin.

[0032]The preparation method includes: light material treatment: spread the graphene oxide powder in the reaction chamber, and after evacuating to 5Pa, feed a mixed gas of methane and Ar gas, wherein the volume ratio of methane is 6%, and control the volume ratio of methane The flow rate is 20sccm, the mixed pressure is adjusted to 200Pa, and then the working temperature is raised to 1000°C. After reaching the working temperature, the RF power is turned on, and the RF power is adjusted to 170W. After processing for 25 minutes, it is cooled with the furnace, and then mixed with magnesium carbonate powder and rosin powder Finally, it is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com