Glass composition, glass powder, glass ink and application of glass ink

A technology of glass composition and glass ink, which is applied in the field of glass composition, glass ink and glass ink, and glass powder. It can solve the problems of high sintering temperature, poor acid and alkali corrosion resistance of glass film materials, and affecting the environmental performance of glass ink, etc. problem, to achieve the effect of improving clarification temperature, improving chemical stability, and lower glass transition temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

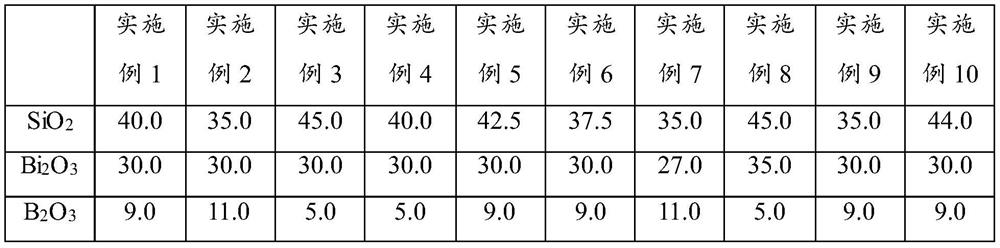

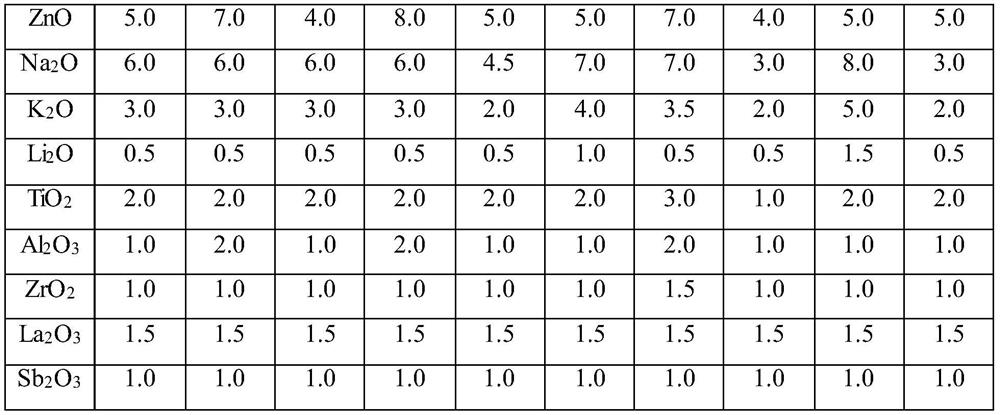

Examples

preparation example Construction

[0048] As an example, glass powder preparation methods include:

[0049] S1. Prepare a glass composition and prepare a homogeneous mixture.

[0050] S2. Put the mixture obtained in step S1 into a high-alumina crucible, and melt it in a high-temperature furnace at 1200-1300° C. for 60-120 minutes.

[0051] Wherein, the melting temperature is, for example but not limited to, the range between any two of 1200°C, 1220°C, 1240°C, 1250°C, 1260°C, 1280°C and 1300°C; the melting time is for example but not limited to 60min, 70min, Any point value of 80min, 90min, 100min, 110min and 120min or any range value between the two.

[0052] S3. Perform pure water cooling water quenching on the molten glass obtained in step S2 to obtain water-quenched cullet.

[0053] S4. Dry the water-quenched cullet obtained in the step S3 and perform ball milling.

[0054] S5. Pass the powder obtained by pulverizing in step S4 through a standard sieve of 300-500 meshes, and use the under-sieve as glass p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com