Modification method of natural graphite negative electrode material

A technology of natural graphite and negative electrode material, applied in the direction of negative electrode, battery electrode, active material electrode, etc., can solve the problems of increased surface and bulk defects, increased interlayer spacing, unfavorable electrochemical performance of graphite, etc., to improve rate performance and low temperature performance, the effect of increasing the interplanar spacing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] In a glove box filled with argon, mix natural graphite powder and sodium powder at a mass ratio of 100:1, and grind in an agate mortar for 10 min to disperse the powder evenly. The mixed powder was transferred to a tube furnace filled with argon, and the temperature was raised to 300 °C at a rate of 5 °C / min for 1 h, and then cooled with the furnace to obtain a modified natural graphite anode material pre-embedded with Na.

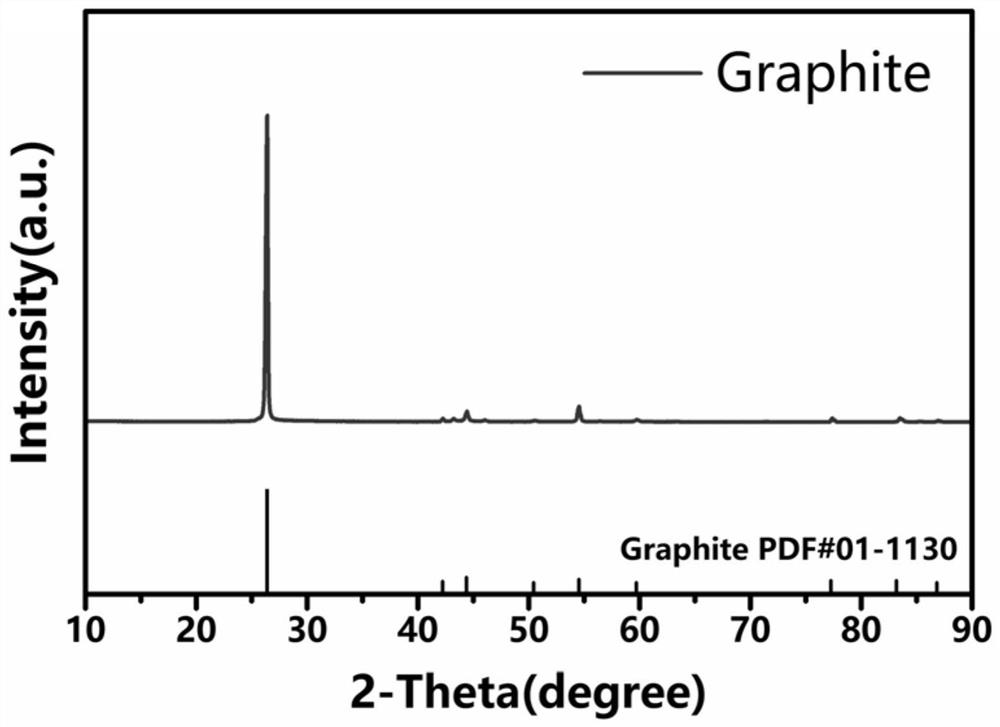

[0058] Figure 4 It is the XRD pattern of modified natural graphite, and the results show that its peak shape is not significantly different from that of Comparative Example 1, and the long-range order is preserved, but the position of the main peak shifts to the left to 26.29°, indicating that the (002) interplanar spacing of graphite increases. Big.

[0059] Figure 5 This is the SEM image of modified natural graphite, and the morphology of natural graphite modified by thermal doping process has no obvious change.

Embodiment 2

[0061] Weigh LiFePO according to the mass ratio of 100:1 4 and Na 2 CO 3 Powder, with absolute ethanol as solvent, ball milled at 450r / min for 30min to mix the powder evenly to obtain large ion premixed LiFePO 4 ; According to the same electrode preparation and CR2025 button battery assembly method as in Comparative Example 2, the LiFePO premixed with large ions was used respectively 4 As the positive electrode, natural graphite is used as the negative electrode to assemble the button battery.

[0062] In the voltage window of 2.5 ~ 3.65V, the constant current charge and discharge tests were carried out on the battery at different current densities. The SEM of the electrode after 300 cycles at a current density of 1C is as follows: Figure 6 As shown, the microscopic morphology of the electrode surface is similar to that of Comparative Example 2. The formation of a solid electrolyte interface film was also observed on the surface, and the thickness did not change significa...

Embodiment 3

[0064] In a glove box filled with argon atmosphere, weigh 1M NaPF 6 , the solvent is 0.8mL electrolyte solution of EC, DEM and EMC mixed solution with a volume ratio of 1:1:1; containing 1M LiPF 6 , the solvent is 20mL of electrolyte solution of EC, DEM and EMC mixed solution with a volume ratio of 1:1:1. The two electrolytes were mixed and stirred thoroughly to obtain Li + and Na + The electrolyte solution with a molar ratio of 100:1 is recorded as No. 1 electrolyte solution.

[0065] The natural graphite pole piece obtained in Comparative Example 1 was used as the working electrode, the lithium metal sheet was used as the counter electrode, and Celgard2500 was used as the separator, and the above-mentioned No. 1 electrolyte was used to assemble a CR2025 button battery in a glove box filled with an argon atmosphere, wherein each The amount of electrolyte used for each battery is 0.08mL.

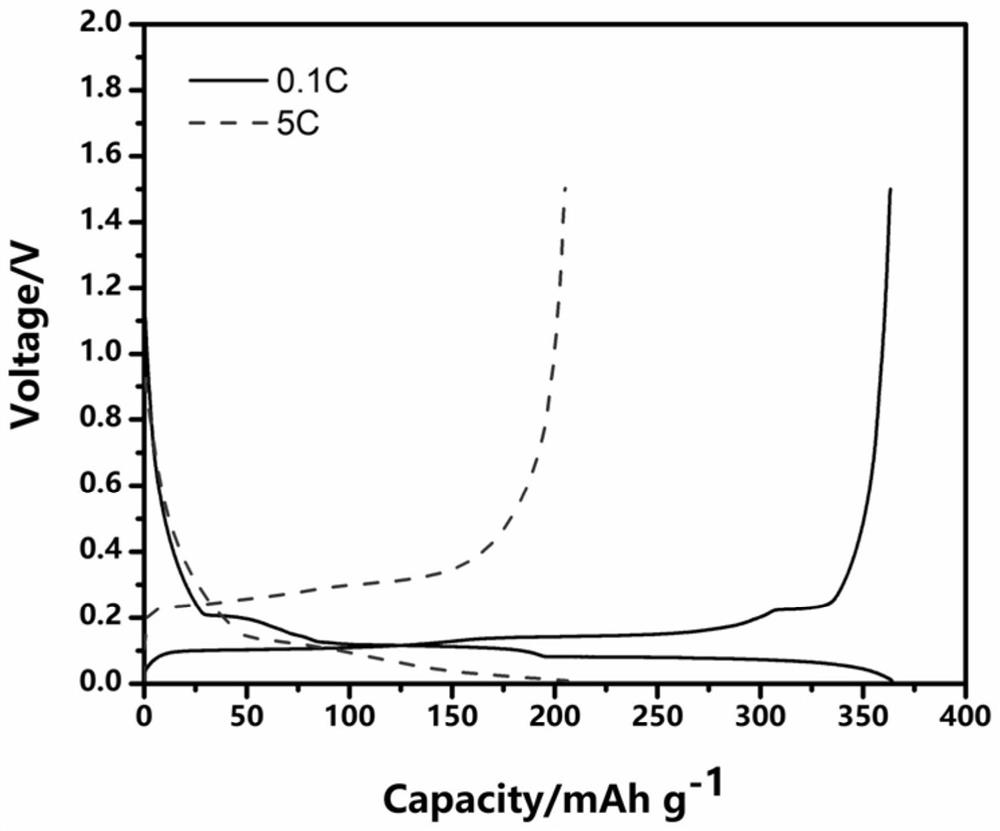

[0066] Such as Figure 7 As shown, within the voltage window of 0.01-1.5V, under th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com