Surface clad lithium ion battery positive material precursor, and preparation method and application thereof

A technology for lithium-ion batteries and positive electrode materials, which is applied to battery electrodes, circuits, electrical components, etc., to reduce side reactions, increase production raw material costs, and reduce collapse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

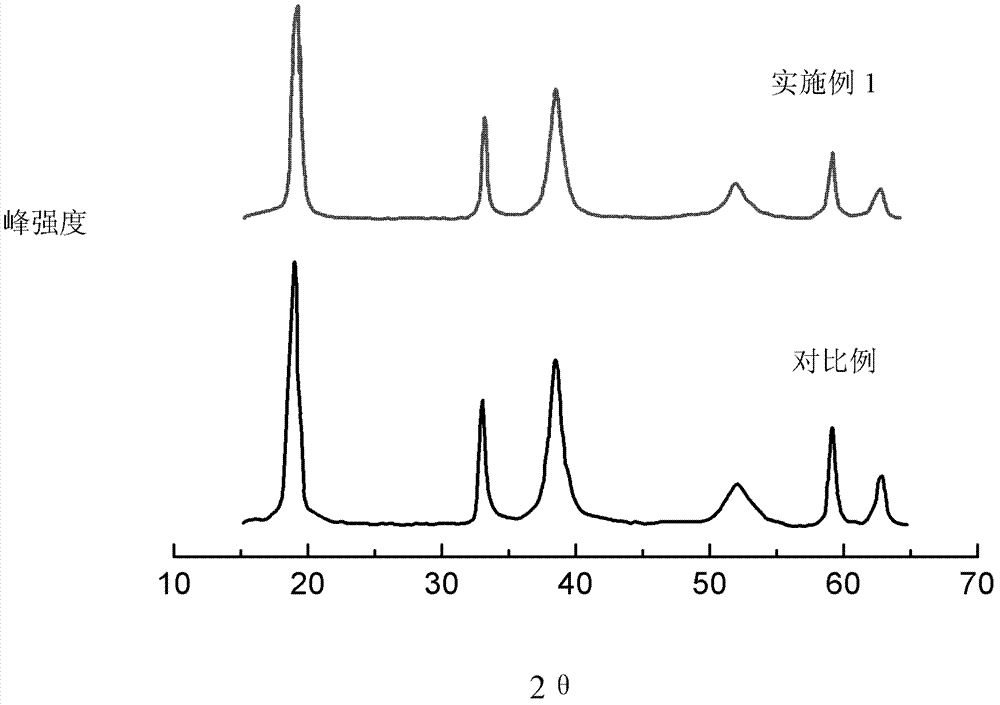

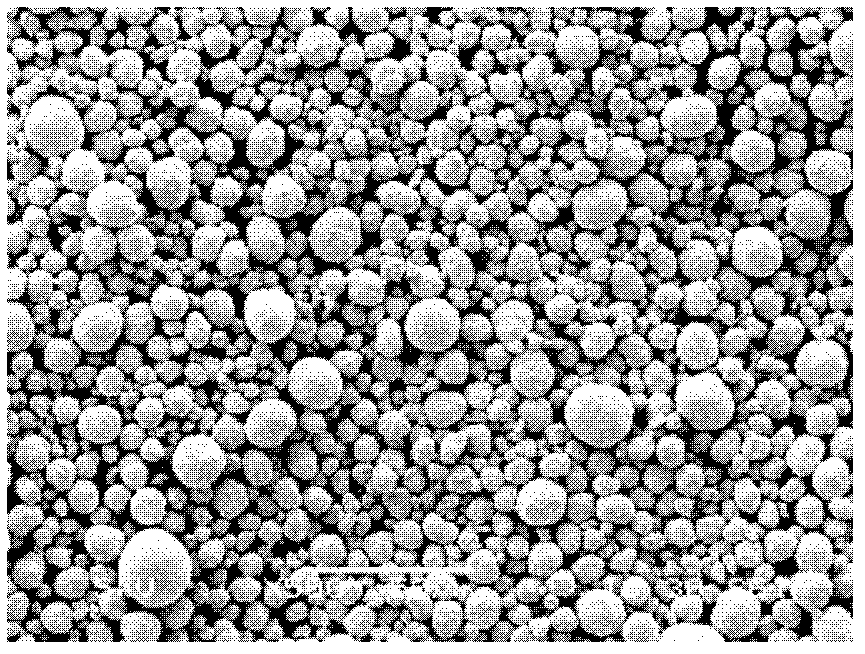

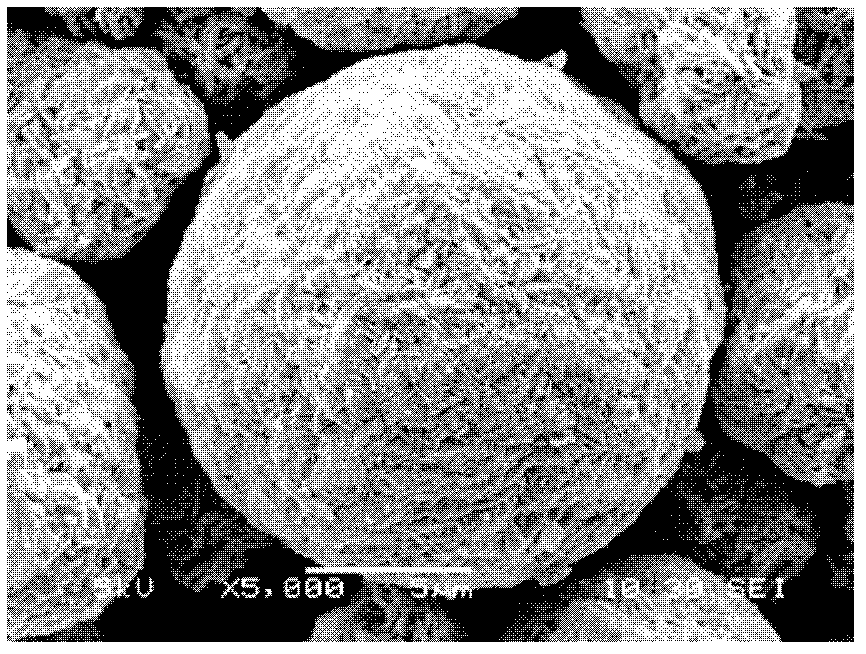

Embodiment 1

[0031]Nickel sulfate, cobalt sulfate, and manganese sulfate were prepared in a molar ratio (1:1:1) to prepare 50 L of salt solution with a concentration of 1.8 mol / L. The prepared solution was injected into a reaction kettle with a rotation speed of 250rps through a metering pump at a rate of 4L / h, and the temperature of the reaction kettle was kept at 50°C. Inject 20% ammonia water and 8mol / L NaOH solution at the same time, adjust the flow rate of the alkali solution, and keep the pH value stable between 9-12 through the pH tester, until the salt solution is completely injected into the reactor, the preparation of the core part of the precursor The reaction is complete, and the particle size of the core part is 5-15 microns. After the reaction is completed, the solid-liquid mixture is filtered through the filter, and after washing to neutrality, the filtered solid part is re-added to the reactor, and 1L of the prepared 1mol / L cobalt sulfate solution is injected at a rate of 0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com