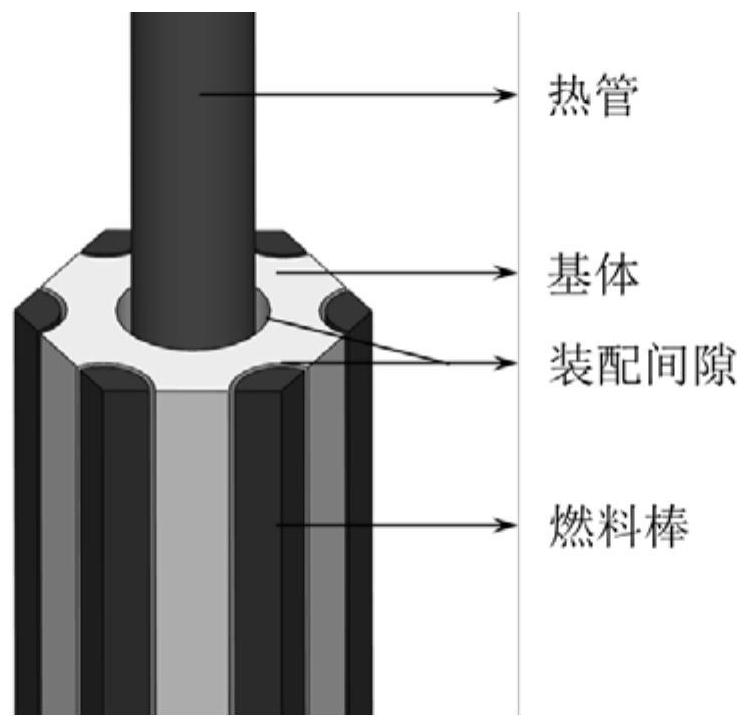

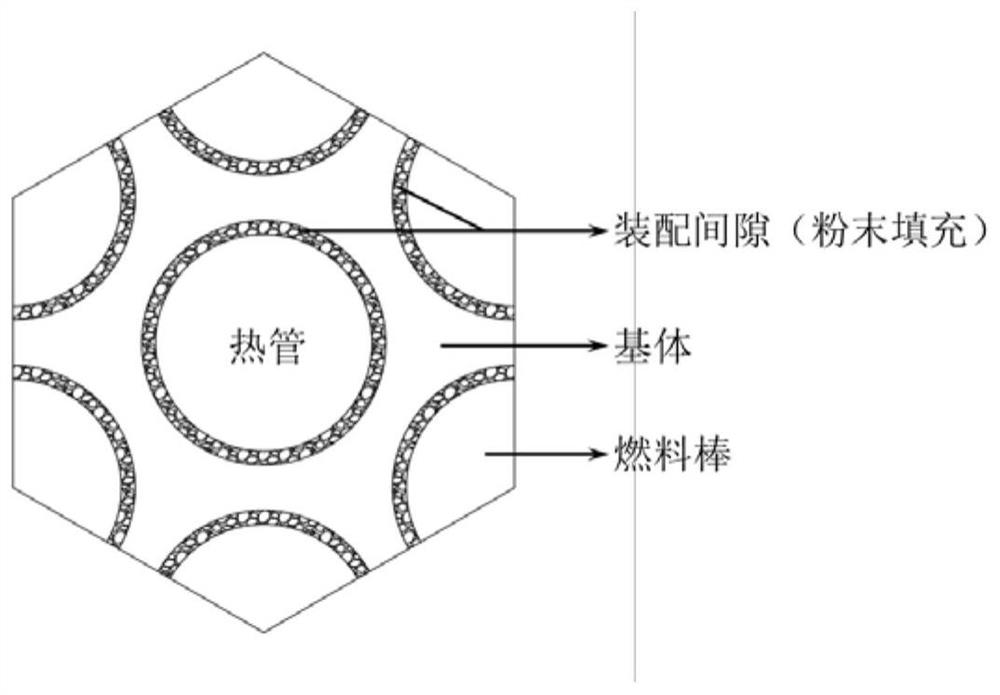

Processing method of heat pipe cooling reactor core

A processing method and reactor technology, applied in reactors, nuclear reactor monitoring, moderator/core structure, etc., can solve problems such as excessive contact stress between substrate and heat pipes, reduction of reactor safety margin, large temperature difference between fuel rods and heat pipes, etc. , to reduce the difficulty of machining and assembly, improve the safety margin, and reduce the effect of contact stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] In this embodiment, the powder flowability of the powder depend on the weight 50g to flow through a standard funnel required to represent, the shorter the time, the better the flow of the.

[0043] Effective thermal conductivity of the powder is measured by the radial heat flow method. Experimental section radial heat flow method and mainly composed of a cylindrical heating rod consisting of stainless steel, the cylindrical wall thickness of 2mm, the outer diameter of 80mm; the heating rod heated length 600mm, diameter 20mm, the heating section aspect ratio of 30: 1. To ensure the uniformity of the axial power of the heating rods, the heating wire is wound evenly on the heating rod. Both ends of the test section comprising three cotton silicate insulation to reduce heat loss axially, so that central region of the test section reaches approximately a one-dimensional radial thermal conductivity. Experiments using a thinner cylindrical wall section of the insulation layer, in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com