Production method for SPCC-W black skin steel plate

A technology of SPCC-W and production method, which is applied in the field of cold processing and heat treatment of iron and steel materials, can solve problems such as product degradation and bonding, and achieve the effects of improved surface quality, low gas consumption, and reduced annealing temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

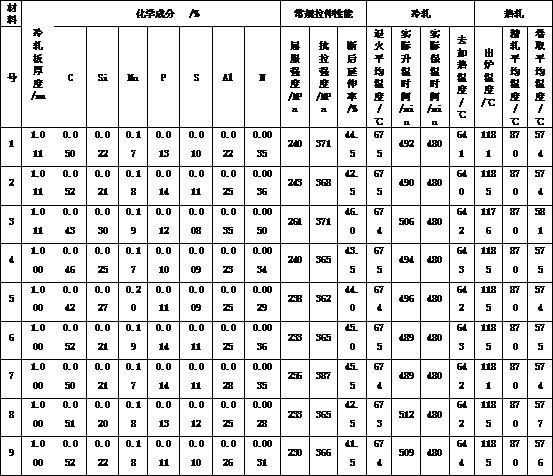

[0010] A production method of SPCC-W black skin steel plate, 1, the silicon content in the steel is: 0.02%≤[Si]≤0.030%; 2, the thickness of the raw material coil of the black skin steel coil is 2.75mm, the cold rolling reduction rate 74.55%; the crimp tensile stress of cold-rolled coils is controlled within 30Mpa; 3. The bell annealing process is designed as follows, the protective medium is protected by nitrogen, and the heating rate is 85-90°C / h in the temperature range of 0-440°C. Keep warm at 440°C for 3 hours to ensure that the emulsion residue on the surface of the rolled steel coil is fully volatilized, heat at 440-675°C at a heating rate of 41-51°C / h, set the annealing temperature at 675°C, and keep warm for 8 hours. The cooling time of the heating cover is set to 0.5 hours, and the temperature of the heating cover is 630-650°C. When the temperature is higher than 650°C, the cooling cover is continued; Baked at 10°C, ventilated and oxidized on the final cooling platfor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com