A kind of lead-free piezoelectric ceramic material for ventilator and preparation method thereof

A lead-free piezoelectric and ceramic material technology, applied in the field of electronic ceramic materials, can solve the problems of poor preparation stability, nervous system poisoning, easy deviation of stoichiometry of PZT piezoelectric ceramics, etc., and achieves high density, good electrical performance, The effect of improving preparation stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

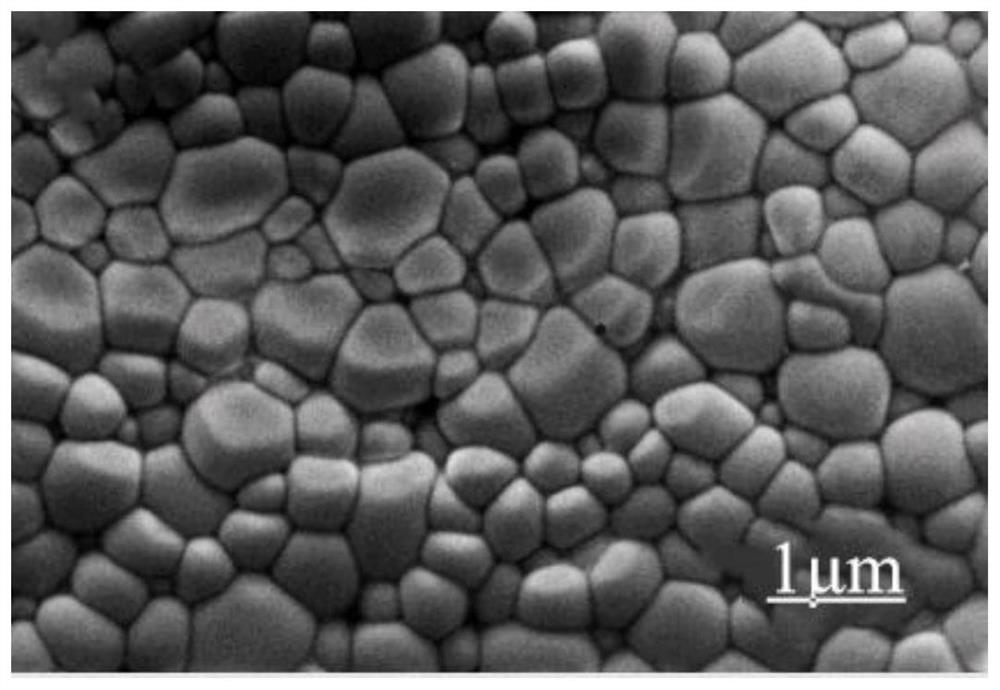

Image

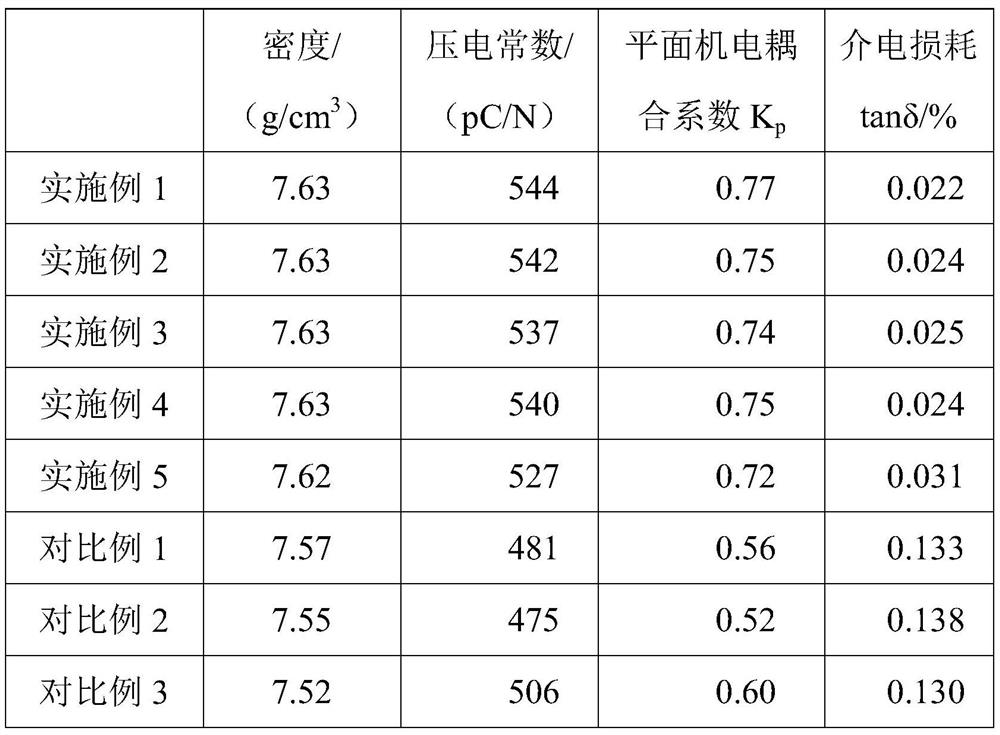

Examples

Embodiment 1

[0035] A lead-free piezoelectric ceramic material for ventilator, represented by the following chemical formula: 0.65 (Bi 0.50 Na 0.50 )TiO 3 -0.25LiNbO 3 -0.10 (Bi 0.75 K 0.25 )HfO 3 -0.15%La 2 O 3 -0.05% LiBiO 2

[0036] Its preparation method is as follows:

[0037] will Bi 2 O 3 , TiO 2, Na 2 CO 3 , The molten salt is weighed and proportioned, the molten salt is composed of NaCl and KCl according to the mass ratio of 1:1, and the amount of molten salt is Bi 2 O 3 , TiO 2 , Na 2 CO 3 3 times the total mass, use anhydrous ethanol as the ball milling medium, dry the ball for 15 hours once, pre-burn at 700°C for 2 hours, then use deionized water as the ball milling medium, dry the ball for 15 hours for the second time, and wash it with water until no Cl - detected, dried, obtained (Bi 0.50 Na 0.50 )TiO 3 , the Li 2 CO 3 , Nb 2 O 5 , The molten salt is weighed and proportioned, the molten salt is composed of NaCl and KCl according to the mass ratio of ...

Embodiment 2

[0039] A lead-free piezoelectric ceramic material for ventilator, represented by the following chemical formula:

[0040] 0.65(Bi 0.50 Na 0.50 )TiO 3 -0.25LiNbO 3 -0.10 (Bi 0.75 K 0.25 )HfO 3 -0.15%La 2 O 3 -0.05% LiBiO 2

[0041] Its preparation method is as follows:

[0042] will Bi 2 O 3 , TiO 2 , Na 2 CO 3 , The molten salt is weighed and proportioned, the molten salt is composed of NaCl and KCl according to the mass ratio of 1:1, and the amount of molten salt is Bi 2 O 3 , TiO 2 , Na 2 CO 3 5 times of the total mass, use absolute ethanol as the ball milling medium, dry after the first ball milling for 10 hours, pre-burn at 700 °C for 2 hours, then use deionized water as the ball milling medium, dry after the second ball milling for 10 hours, and wash with water until no Cl - detected, dried, obtained (Bi 0.50 Na 0.50 )TiO 3 , the Li 2 CO 3 , Nb 2 O 5 , The molten salt is weighed and proportioned, the molten salt is composed of NaCl and KCl accor...

Embodiment 3

[0044] A lead-free piezoelectric ceramic material for ventilator, represented by the following chemical formula:

[0045] 0.65(Bi 0.50 Na 0.50 )TiO 3 -0.25LiNbO 3 -0.10 (Bi 0.75 K 0.25 )HfO 3 -0.15%La 2 O 3 -0.05% LiBiO 2

[0046] Its preparation method is as follows:

[0047] will Bi 2 O 3 , TiO 2 , Na 2 CO 3 , The molten salt is weighed and proportioned, the molten salt is composed of NaCl and KCl according to the mass ratio of 1:1, and the amount of molten salt is Bi 2 O 3 , TiO 2 , Na 2 CO 3 10 times the total mass, use anhydrous ethanol as the ball-milling medium, dry after the first ball-milling for 15 hours, pre-burn at 700°C for 4 hours, then use deionized water as the ball-milling medium, dry the ball-milling for 15 hours for the second time, and wash with water until no Cl - detected, dried, obtained (Bi 0.50 Na 0.50 )TiO 3 , the Li 2 CO 3 , Nb 2 O 5 , The molten salt is weighed and proportioned, the molten salt is composed of NaCl and KCl ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| piezoelectric charge coefficient | aaaaa | aaaaa |

| dielectric loss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com