Thin wool and cashmere fabric

A cashmere and wool technology, applied in the field of fabric textiles, can solve the problems affecting the appearance of cashmere fabrics, thread jumping, and fluff disorder, etc., and achieve the effects of improving hand feeling, good thermal performance, and improving comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

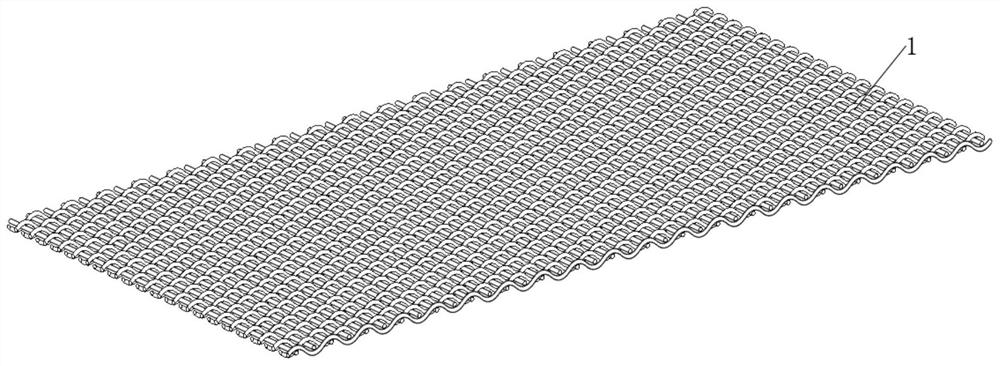

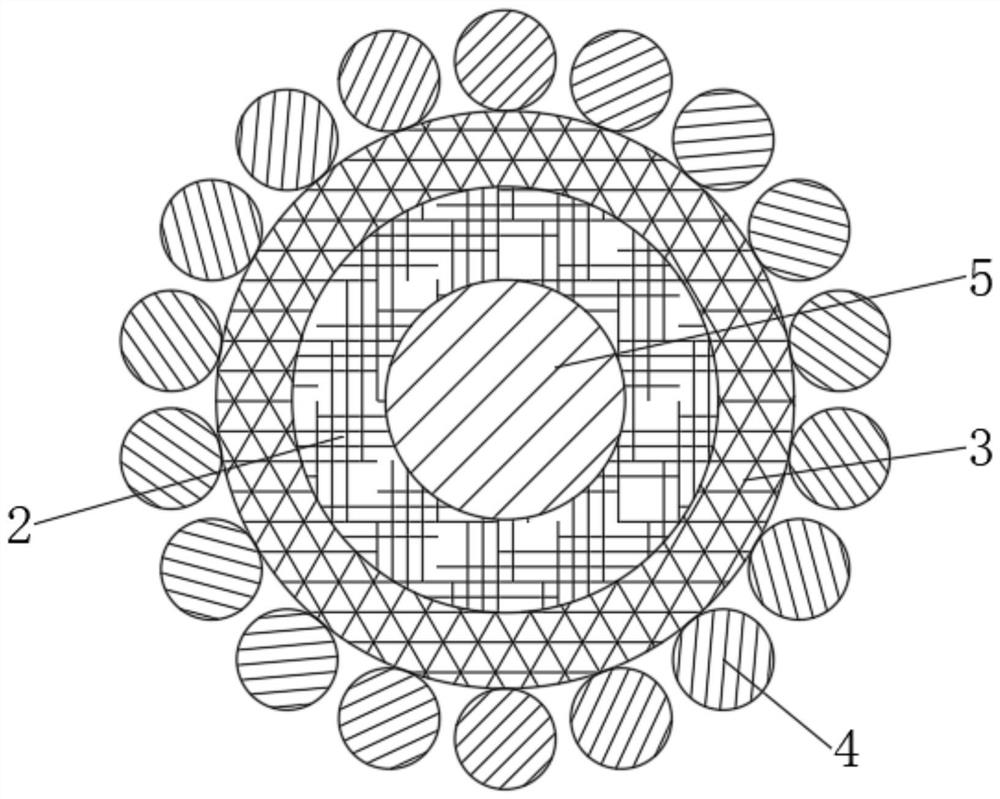

[0030] Such as Figure 1-2 As shown, the embodiment of the present invention provides a kind of thin wool cashmere fabric, comprises fabric body 1, and fabric body 1 is woven by warp yarn and weft yarn, and warp yarn and weft yarn are made of line core 5, wool 2, cashmere 3, core-spun yarn 4 components; the density of warp yarns is 230 yarns / 10cm, the density of weft yarns is 160 yarns / 10cm, and the specification of fabric body 1 is 45*45 / 230*160 / 60.

[0031] Preferably, the outer surface of the wire core 5 is fixedly connected to the inner surface of the wool layer 2, the outer surface of the wool layer 2 is fixedly connected to the inner surface of the cashmere layer 3, and the outer surface of the cashmere layer 3 is fixed to the inner surface of the core-spun yarn 4. connect.

[0032] Preferably, the following processing techniques are included:

[0033] S1. Hairless carding: carding the cashmere, combing the miscellaneous hairs, leaving no wool;

[0034] S2. Dyeing: Dy...

Embodiment 2

[0044] Such as Figure 1-2 As shown, the embodiment of the present invention provides a kind of thin wool cashmere fabric, comprises fabric body 1, and fabric body 1 is woven by warp yarn and weft yarn, and warp yarn and weft yarn are made of line core 5, wool 2, cashmere 3, core-spun yarn 4 components; the density of warp yarns is 210 yarns / 10cm, the density of weft yarns is 140 yarns / 10cm, and the specification of fabric body 1 is 45*45 / 210*140 / 60.

[0045] Preferably, the outer surface of the wire core 5 is fixedly connected to the inner surface of the wool layer 2, the outer surface of the wool layer 2 is fixedly connected to the inner surface of the cashmere layer 3, and the outer surface of the cashmere layer 3 is fixed to the inner surface of the core-spun yarn 4. connect.

[0046] Preferably, the following processing techniques are included:

[0047] S1. Hairless carding: carding the cashmere, combing the miscellaneous hairs, leaving no wool;

[0048] S2. Dyeing: Dy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com