Heat treatment method for optimizing mechanical property of additive manufacturing GH3536 nickel-based superalloy

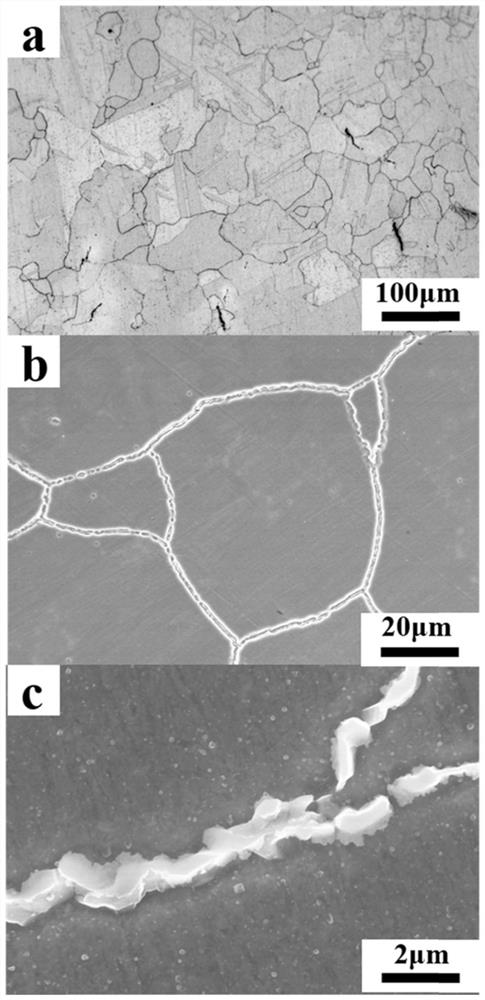

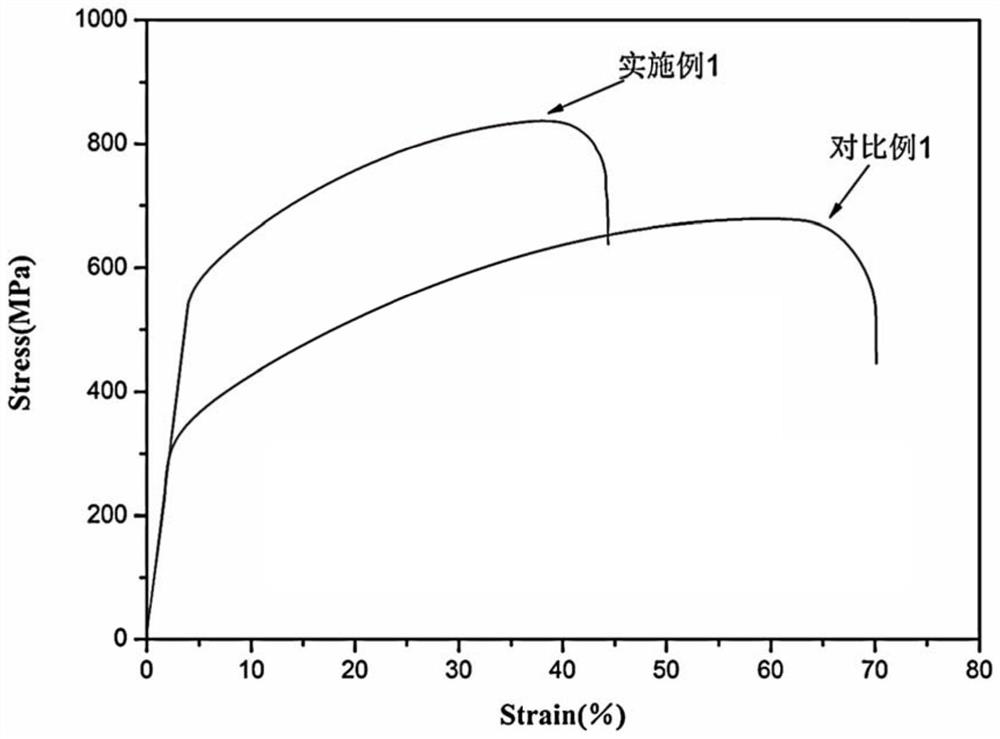

A technology of nickel-based superalloy, GH3536, is applied in the field of heat treatment to optimize the mechanical properties of GH3536 nickel-based superalloy by additive manufacturing. Better than, the number of carbides reduced, the effect of a wide range of applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

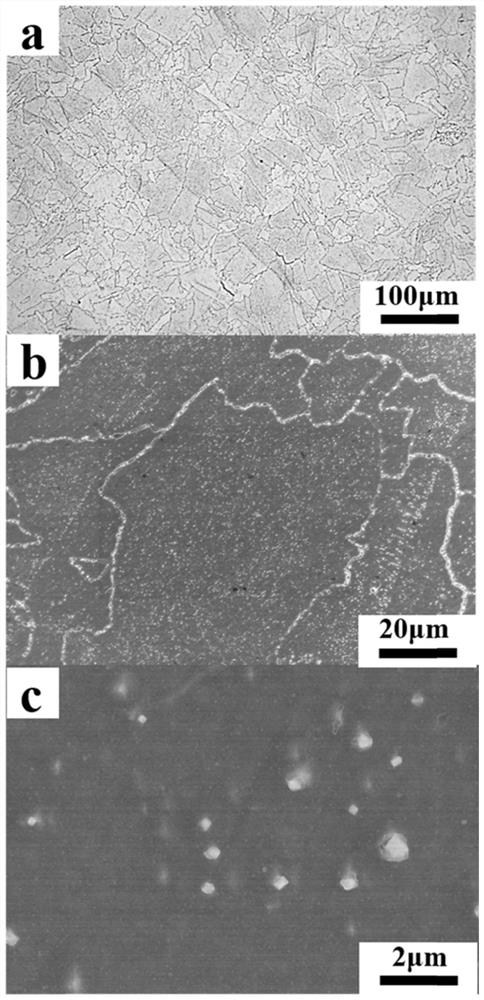

Embodiment 1

[0032] This embodiment provides a heat treatment method for optimizing the mechanical properties of additive manufacturing GH3536 nickel-based superalloy, which specifically includes the following:

[0033] Step S1: Using laser selective melting forming equipment (manufacturer: Tianjin Raiming Laser Technology Co., Ltd., model: LM-150A), process the spherical powder of GH3536 nickel-based high-temperature powder into a block sample, and the particle size of the spherical powder ranges from 15 to 45 μm . The forming parameters of laser selective melting forming GH3536 nickel-based superalloy: laser power 190W, powder coating thickness 35μm, layer rotation 67°, substrate preheating 90℃, scanning speed 900mm / s, scanning line spacing 75μm, 5mm strip laser Bi-directional scanning.

[0034] Step S2: raise the temperature of the muffle furnace to 1050° C., quickly put the additively manufactured GH3536 alloy sample obtained in step 1 into the muffle furnace for solution heat treatme...

Embodiment 2

[0046] This embodiment provides a heat treatment method for optimizing the mechanical properties of additive manufacturing GH3536 nickel-based superalloy, which specifically includes the following:

[0047] Step S1: Using laser selective melting forming equipment (manufacturer: Tianjin Raiming Laser Technology Co., Ltd., model: LM-150A), process the spherical powder of GH3536 nickel-based high-temperature powder into a block sample, and the particle size of the spherical powder ranges from 15 to 45 μm . The forming parameters of laser selective melting forming GH3536 nickel-based superalloy: laser power 190W, powder coating thickness 35μm, layer rotation 67°, substrate preheating 90℃, scanning speed 1000mm / s, scanning line spacing 75μm, 5mm strip laser Bi-directional scanning.

[0048] Step S2: Raise the temperature of the muffle furnace to 1030° C., quickly put the additively manufactured GH3536 alloy sample obtained in step 1 into the muffle furnace for solution heat treatm...

Embodiment 3

[0051] This embodiment provides a heat treatment method for optimizing the mechanical properties of additive manufacturing GH3536 nickel-based superalloy, which specifically includes the following:

[0052] Step S1: Using laser selective melting forming equipment (manufacturer: Tianjin Raiming Laser Technology Co., Ltd., model: LM-150A), process the spherical powder of GH3536 nickel-based high-temperature powder into a block sample, and the particle size of the spherical powder ranges from 15 to 45 μm . The forming parameters of laser selective melting forming GH3536 nickel-based superalloy: laser power 190W, powder coating thickness 35μm, layer rotation 67°, substrate preheating 90℃, scanning speed 1000mm / s, scanning line spacing 75μm, 5mm strip laser Bi-directional scanning.

[0053] Step S2: raise the temperature of the muffle furnace to 1060° C., quickly put the additively manufactured GH3536 alloy sample obtained in step 1 into the muffle furnace for solution heat treatm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com