High-entropy rare earth zirconate nano aerogel as well as preparation method and application thereof

A nano-airgel and zirconate technology, which is applied in the direction of airgel preparation, nanotechnology, chemical instruments and methods, etc., can solve the problems of poor mechanical properties, high-entropy rare earth elements, enhanced phonon scattering effect, and reduced activation energy, etc. problem, to achieve the effect of simple and effective preparation method, high temperature stability, simple and feasible method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

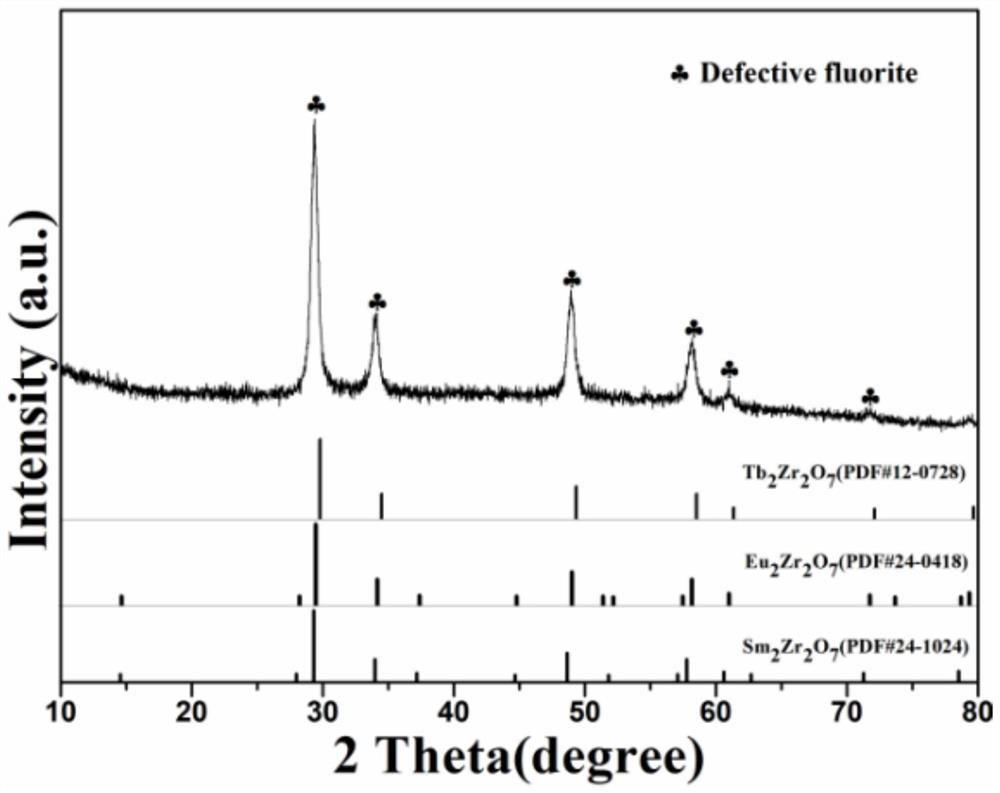

Embodiment 1

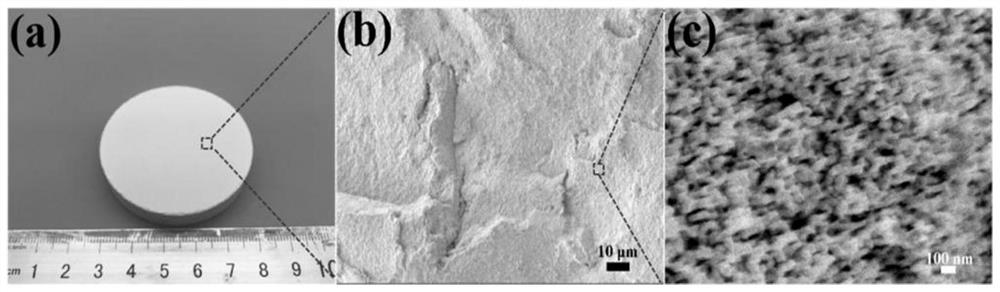

[0053] A preparation method of high-entropy rare earth zirconate nano-airgel:

[0054] (1) Dissolve 80 g of thermoplastic phenolic resin 3520f in 100 mL (about 80 g) of absolute ethanol solution, stir magnetically at room temperature for 1 hour, add 16 g of hexamethylenetetramine, and continue magnetically stirring for 1 hour to obtain mixed solution A.

[0055] (2) Add 0.02 mol of zirconium nitrate pentahydrate to mixed solution A and magnetically stir for 0.5 h to obtain mixed solution B.

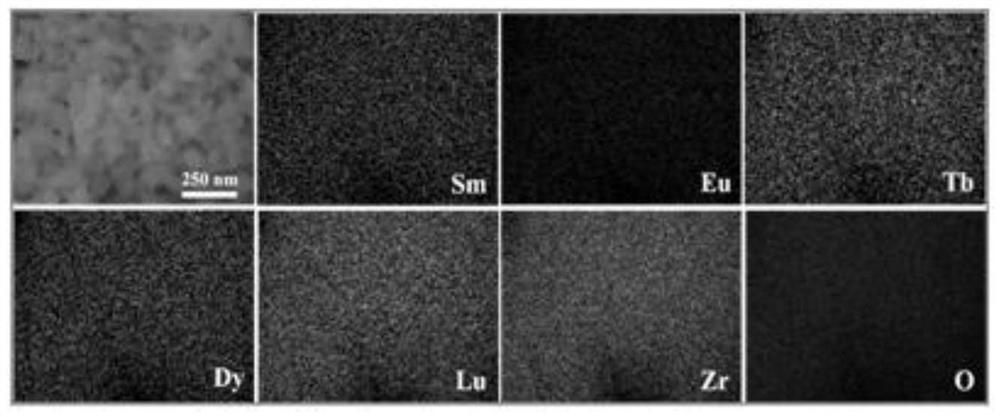

[0056] (3) Add samarium nitrate, europium nitrate, terbium nitrate, dysprosium nitrate and lutetium nitrate into the mixed solution B, and stir magnetically for 0.5 h to obtain the mixed solution C.

[0057] (4) Transfer the mixed solution C to a polytetrafluoroethylene-lined autoclave, place it in a blast drying oven, and keep it warm at 80°C for 48 hours. After the autoclave naturally cools down to room temperature, a wet gel is obtained.

[0058] (5) The wet gel obtained in step (4) w...

Embodiment 2

[0062] Same as Example 1, the difference is that the calcination temperature in step (7) is 1100°C.

Embodiment 3

[0064] Same as Example 1, the difference is that the calcination temperature in step (7) is 1300°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com