Molybdenum-nickel-based multi-element alloy rotary target material and preparation method thereof

A multi-element alloy and rotating target technology, which is applied in metal material coating process, ion implantation plating, coating, etc., can solve problems such as difficult target preparation, removal, sputtering coating arcing, etc., and achieve obvious market competition The effect of reducing power and sintering cost and improving comprehensive performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

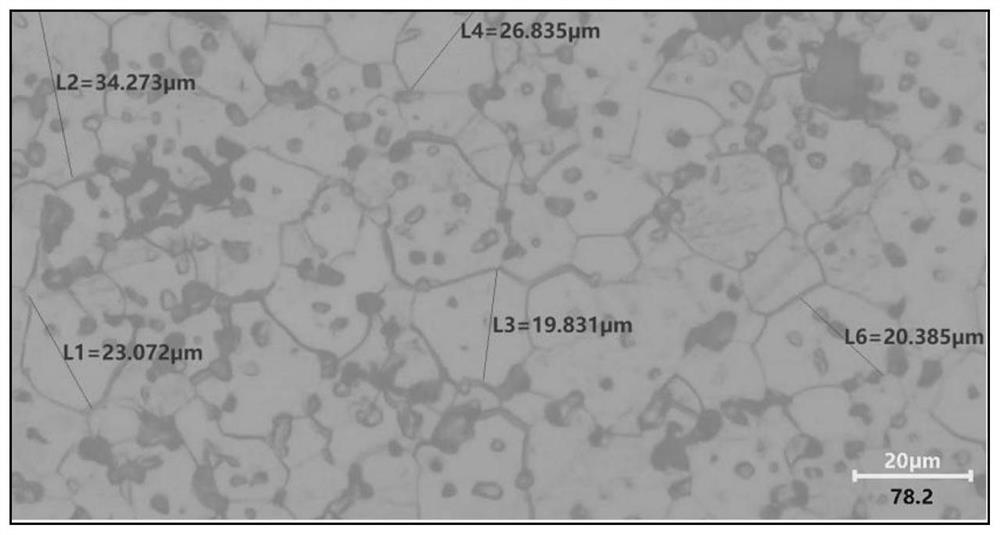

[0028] Preparation of Mo 40 Ni 30 Ti 15 al 15

[0029] S1. Use Mo powder with a particle size of 3-7um, an oxygen content of ≤1000ppm, and a purity greater than 99.95%; Ni powder is electrolytic nickel powder, with a purity of greater than 99.9%, a particle size of 6-12um, and an oxygen content of ≤2000ppm; atomized and granulated Ti 50 al 50 Alloy powder, particle size 35-60um, oxygen content ≤3000ppm. Mix according to the above atomic ratio, put it in a vacuum furnace at 1000°C, and the vacuum degree is not less than 10 -2 Pa was subjected to vacuum deoxidation purification treatment for 2h.

[0030] S2. The vacuum-treated powder is mixed by mechanical ball milling, the ball-to-material ratio is 3:1, the rotation speed is 170 R / M, and the argon gas protection ball mill is mixed for 12 hours. The inner lining and balls of the ball mill are made of pure molybdenum.

[0031] S3. Fill the ball mill powder into the tubular mold cavity. The powder filling process uses a vib...

Embodiment 2

[0038] Preparation of Mo 52 Ni 25 Ti 15 al 8

[0039] S1. Use Mo powder with a particle size of 3-7um, an oxygen content of ≤1000ppm, and a purity greater than 99.95%; Ni powder is electrolytic nickel powder, with a purity of greater than 99.9%, a particle size of 6-12um, and an oxygen content of ≤2000ppm; atomized and granulated Ti 70 al 30 Alloy powder, particle size 35-60um, oxygen content ≤3000ppm. Mix according to the above atomic ratio, place in a vacuum furnace at 1030°C, and the vacuum degree is not less than 10 - 2 Pa was subjected to vacuum deoxidation purification treatment for 5h.

[0040] S2. The vacuum-treated powder is mixed by mechanical ball milling, the ball-to-material ratio is 3:1, the rotation speed is 180 R / M, and the argon gas protection ball mill is mixed for 10 hours. The inner lining and balls of the ball mill are made of pure molybdenum.

[0041] S3. Fill the ball mill powder into the tubular mold cavity. The whole powder filling process uses...

Embodiment 3

[0048] Preparation of coating samples, where the target material is Mo 45 -Ni 30 -Ti 15 -Al 10 .

[0049] S1. Use Mo powder with a particle size of 3-7um, an oxygen content of ≤1000ppm, and a purity greater than 99.95%; Ni powder is electrolytic nickel powder, with a purity of greater than 99.9%, a particle size of 6-12um, and an oxygen content of ≤2000ppm; atomized and granulated Ti50AL50at% alloy Powder, particle size 35-60um, oxygen content ≤3000ppm. By atomic ratio Mo 45 -Ni 30 -Ti 15 -Al 10 at% mixed, placed in a vacuum furnace at 1000 ° C, the vacuum degree is not less than 10 -2 pa for vacuum deoxidation purification treatment 1H.

[0050] S2. The vacuum-treated powder is mixed by mechanical ball milling, the ball-to-material ratio is 3:1, the rotation speed is 170 R / M, and the argon gas protection ball mill is mixed for 8 hours. The inner lining and balls of the ball mill are made of pure molybdenum.

[0051] S3. Fill the ball mill powder into the tubular mol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com