Method for selectively extracting cobalt and nickel from nickel sulfide concentrate

A technology of nickel sulfide refining and nickel sulfide, which is applied in the direction of nickel sulfate, cobalt sulfate, process efficiency improvement, etc., to achieve the effect of improving resource utilization, realizing selective and efficient leaching at atmospheric pressure, and reducing environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0113] Embodiment 1: the preparation of nickel sulfide concentrate leachate

[0114] Step 1: mixing the nickel sulfide concentrate with water to form a nickel sulfide concentrate slurry with a concentration of 25%, and ball milling the nickel sulfide concentrate slurry to form an ultra-fine ground nickel sulfide concentrate.

[0115] Step 2, placing the ultra-finely ground nickel sulfide concentrate in a reaction furnace and adding sulfuric acid solution as a leaching solution, and feeding oxygen at a predetermined pressure into the leaching solution to leach the ultrafinely ground nickel sulfide Metal elements in the concentrate to obtain a nickel sulfide concentrate leaching solution, the metal elements at least include copper, iron, cobalt, nickel, magnesium and calcium elements.

[0116] (1) Investigate the effect of fine grinding particle size on the preparation of nickel sulfide concentrate leaching solution

[0117] Wherein, the condition of selective reaction is: the ...

Embodiment 2

[0143] Embodiment 2: remove copper ion and iron ion in nickel sulfide concentrate leachate

[0144] Step 1. Add hydrogen peroxide to the nickel sulfide concentrate leaching solution obtained under the optimized process conditions in Example 1 to oxidize ferrous ions in the leaching solution to ferric ions to form a first solution.

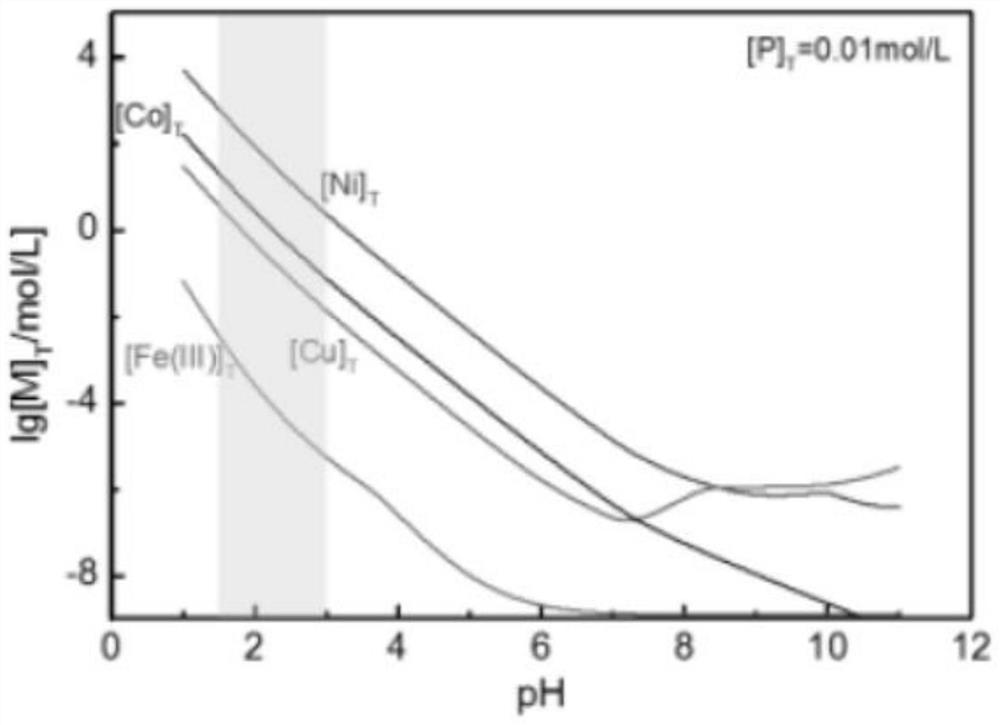

[0145] Step 2, adding phosphate to the first solution, so that the iron ions and copper ions in the first solution react respectively to form copper phosphate and iron phosphate precipitates, and after the reaction is completed, filter to obtain solid-phase copper phosphate respectively slag and iron phosphate slag, obtain the second solution of the liquid phase, that is, the leaching solution from which copper ions and iron ions have been removed; wherein, according to the amount that makes the iron ions and copper ions in the first solution completely precipitated, the phosphoric acid The excess coefficient of the amount of salt used is 1, the re...

Embodiment 3

[0155] Embodiment 3: remove calcium ion and magnesium ion in nickel sulfide concentrate leachate

[0156] The second solution obtained under the optimized process conditions of Example 2, that is, the leaching solution that has removed iron ions and copper ions, is placed in a constant temperature water bath and stirred, and sodium carbonate solution is added so that the second solution reaches a predetermined pH value , adding sodium fluoride to the second solution as a precipitant, the magnesium ions and calcium ions in the second solution react with sodium fluoride, and after the reaction is completed, solid-liquid separation is carried out to obtain a third solution of the liquid phase , that is, the leachate from which calcium and magnesium ions have been removed.

[0157] (1) Investigate the effect of the end point pH value on the removal of calcium ions and magnesium ions in the nickel sulfide concentrate leachate.

[0158] Wherein, the selected reaction conditions are...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| saponification | aaaaa | aaaaa |

| saponification | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com