Difunctional epoxy resin composite material and preparation method thereof

A technology of epoxy resin and composite materials, applied in the direction of plastic recycling, recycling technology, etc., can solve the problems of insufficient ultraviolet shielding performance of epoxy resin, low sensitivity, complex analysis equipment, etc., achieve good ultraviolet shielding function, efficient and non-destructive recycling Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

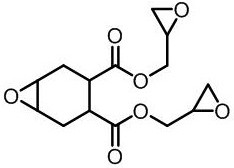

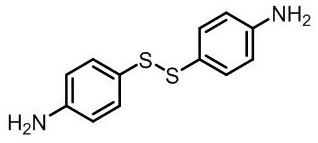

[0030] In this example, diglycidyl 4,5-epoxyhexane-1,2-dicarboxylate was purchased from Tianjin Jindong Chemical Factory Co., Ltd.; 4,4'-dithiodiphenylamine was purchased from Shanghai Anaiji Chemical Co., Ltd., the structure diagram is as follows figure 1 and figure 2 As shown, glass fiber (EW250F) was purchased from Nanjing Glass Fiber Research and Design Institute.

[0031] This embodiment includes an epoxy resin material / resin composite material with dual functions of UV shielding and damage self-reporting, comprising the following steps:

[0032] Pretreatment of M-1 resin and curing agent:

[0033] 100 grams of 4,5-epoxyhexane-1,2-dicarboxylic acid diglycidyl ester and 62 grams of 4,4'-dithiodianiline were uniformly mixed at 55°C to obtain glue A.

[0034] Post-pouring treatment of M-2 resin material:

[0035] Vacuumize the glue A obtained in step M-1 to remove air bubbles, then pour it into a metal mold and undergo a solidification process of 100°C / 1h+160°C / 2h+200°...

Embodiment 2

[0043] In this example, diglycidyl 4,5-epoxyhexane-1,2-dicarboxylate was purchased from Tianjin Jindong Chemical Factory Co., Ltd.; 4,4'-dithiodiphenylamine was purchased from Shanghai Anaiji Chemical Co., Ltd. purchase; glass fiber (EW250F) purchased from Nanjing Glass Fiber Research and Design Institute.

[0044] This embodiment includes an epoxy resin material / resin composite material with dual functions of UV shielding and damage self-reporting, comprising the following steps:

[0045] Pretreatment of M-1 resin and curing agent:

[0046] 100 grams of 4,5-epoxyhexane-1,2-dicarboxylic acid diglycidyl ester and 75 grams of 4,4'-dithiodianiline were uniformly mixed at 55°C to obtain glue B.

[0047] Post-pouring treatment of M-2 resin material:

[0048] Vacuumize the glue B obtained in step M-1 to remove air bubbles, then pour it into a metal mold and undergo a curing process of 100°C / 1h+160°C / 2h+200°C / 2h for casting and molding, and cool to obtain a UV shielding and damage ...

Embodiment 3

[0055] In this example, diglycidyl 4,5-epoxyhexane-1,2-dicarboxylate was purchased from Tianjin Jindong Chemical Factory Co., Ltd.; 4,4'-dithiodiphenylamine was purchased from Shanghai Anaiji Chemical Co., Ltd. purchase; glass fiber (EW250F) purchased from Nanjing Glass Fiber Research and Design Institute.

[0056] This embodiment includes an epoxy resin material / resin composite material with dual functions of UV shielding and damage self-reporting, comprising the following steps:

[0057] Pretreatment of M-1 resin and curing agent:

[0058] 100 grams of 4,5-epoxyhexane-1,2-dicarboxylic acid diglycidyl ester and 87 grams of 4,4'-dithiodianiline were uniformly mixed at 55°C to obtain glue C.

[0059] Post-pouring treatment of M-2 resin material:

[0060] Vacuumize the glue C in step M-1 to remove air bubbles, then pour it into a metal mold and undergo a curing process of 100°C / 1h+160°C / 2h+200°C / 2h for casting and molding, and cool to obtain a product with UV shielding and dam...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com