Integrated shielding material composite structure

A technology of shielding materials and composite structures, which is applied in shielding, reactors, nuclear engineering, etc., to achieve the effects of easy production and installation, low cost, and on-site construction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

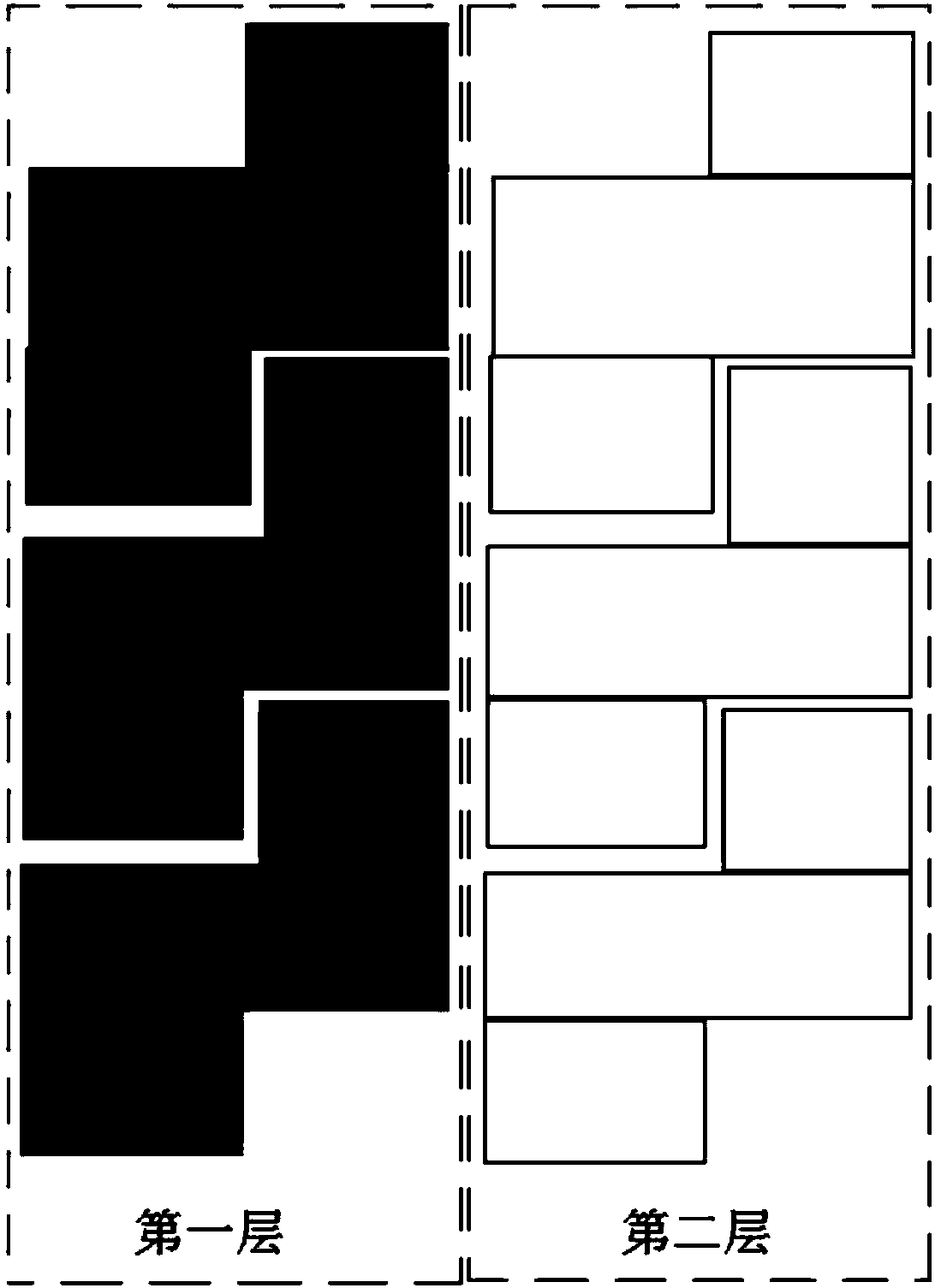

[0023] In one application, the shielding structure needs to be responsible for attenuating the flow of radiated neutrons and photons from one side of it. According to theoretical analysis, it is known that the dose rate of the exit surface of the shielding structure is mainly caused by the incident fast neutrons, so the optimal shielding scheme obtained from the shielding optimization analysis is to use iron ( image 3 gray blocks shown) and polyethylene ( image 3 Shown as white blocks) are layered to shield incident particles.

[0024] The integrated shielding material composite structure in this embodiment includes several "layers" arranged inside and outside, and each "layer" includes several "Z"-shaped turning bodies, and installations are installed between adjacent turning bodies of each "layer". gap. Each block of shielding material adopts two shielding materials of iron and polyethylene. Specifically, for each turning body, the optimal spatial distribution scheme is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com