Braided sleeve for cable and its production method

A sleeve and cable technology, applied in the field of cable braided sleeve and its production, can solve the problems of poor flexibility, easy breakage, easy adhesion, etc., and achieve the effects of wide adaptable temperature range, strong tensile strength and good flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

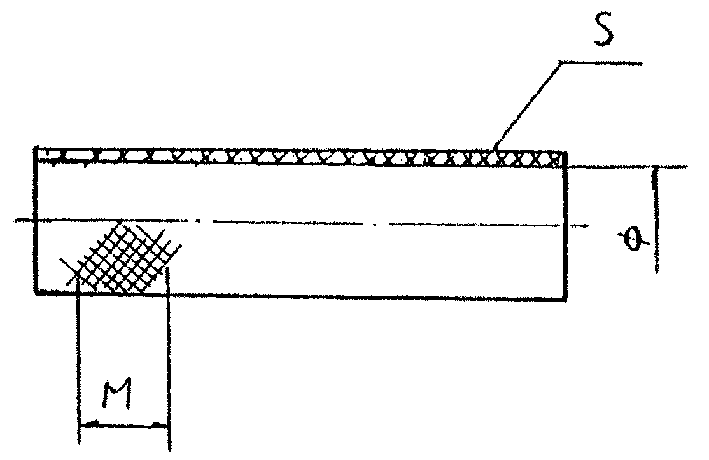

[0010] The cable braided sleeve shown in the attached figure is braided by 0.18mm antimagnetic metal fiber. The method is composed of tube making, ball beating, weaving, winding molding, and packaging process steps. The weaving process parameters are shown in Table 1.

[0011] Nominal inner diameter

φmm

wall thickness

smm

Weaving density

M pieces / cm

Number of lines

bloom × root

12

0.4±0.1

40±1

64×3

14

0.4±0.1

42±1

64×4

16

0.5±0.1

44±1

64×5

18

0.5±0.1

46±1

72×3

20

0.5±0.1

48±1

72×4

22

0.6±0.1

50±1

72×5

24

0.6±0.1

52±1

72×6

26

0.6±0.1

54±1

84×3

28

0.6±0.1

56±1

84×4

30

0.7±0.1

58±1

84×5

32

0.8±0.1

60±1

84×6

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com