Preparation method of hard alloy and hard alloy prepared through method

A cemented carbide and alloy powder technology, applied in the field of alloy materials, can solve the problems affecting the normal progress of the project, the cemented carbide is prone to wear and tear, and cannot meet the development needs, etc., and achieves the effect of reducing the introduction of impurities and improving the purity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

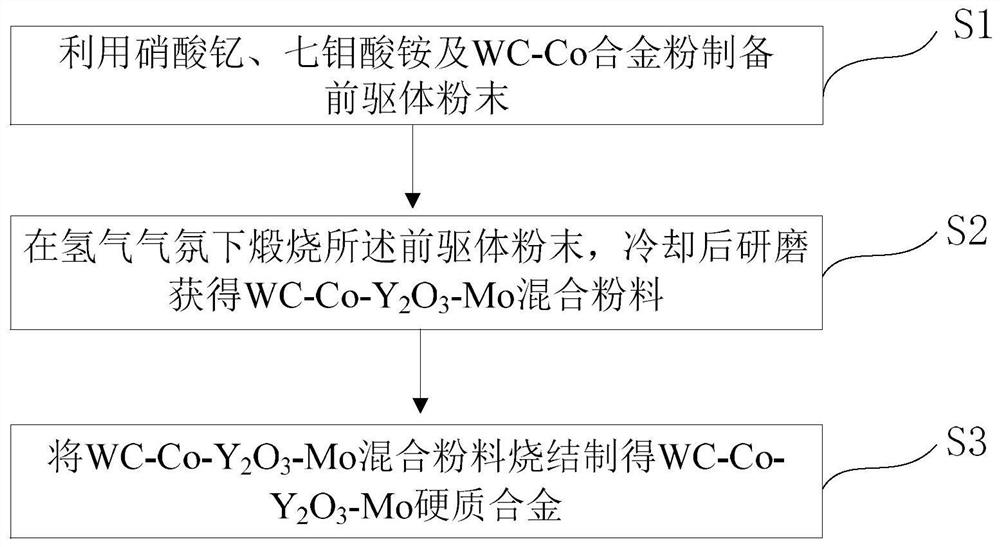

[0027] see figure 1 , figure 1 It is a flowchart of the preparation method of cemented carbide of the present invention. The preparation method of the present invention at least comprises the following steps:

[0028] S1, using Y(NO 3 ) 3 ·6H 2 O, (NH 4 ) 6 Mo 7 o 24 4H 2 Precursor powder prepared from O and WC-Co alloy powder;

[0029] S2. Calcining the precursor powder in a hydrogen atmosphere, cooling and grinding to obtain WC-Co-Y 2 o 3 -Mo mixed powder;

[0030] S3, the WC-Co-Y 2 o 3 -Mo mixed powder sintered to prepare WC-Co-Y 2 o 3 - Mo cemented carbide.

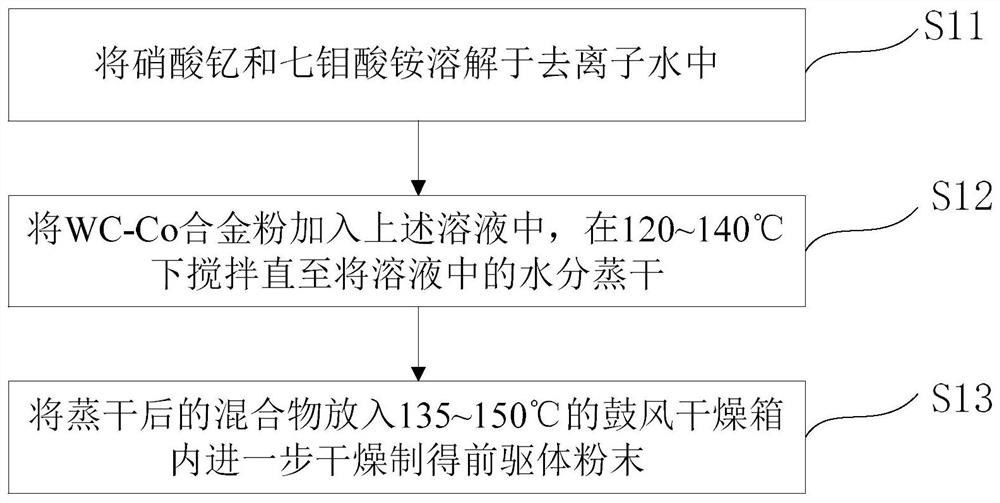

[0031] see figure 2 , figure 2 for figure 1 The flow chart of preparing the precursor powder in step S1 specifically includes the following steps:

[0032] S11, set Y(NO 3 ) 3 ·6H 2 O and (NH 4 ) 6 Mo 7 o 24 4H 2 O dissolved in deionized water;

[0033] S12. Add WC-Co powder into the above solution, and stir at 120-140° C. until the water in the solution is evaporated to dryness;

[00...

Embodiment 1

[0054] WC-Co-Y prepared in this example 2 o 3 -Y in Mo cemented carbide 2 o 3 0.8 wt%, Mo 2.7 wt%, and WC-Co 96.5 wt%.

[0055] The preparation process is as follows: first according to the Y in the cemented carbide 2 o 3 The content of , Mo and WC-Co is calculated according to formula (1) and formula (2) Y(NO 3 ) 3 ·6H 2 O, (NH 4 ) 6 Mo 7 o 24 4H 2 The amount of O and WC-Co should be weighed according to the calculated amount.

[0056] 1. Preparing the precursor: the weighed Y(NO 3 ) 3 ·6H 2 O, (NH 4 ) 6 Mo 7 o 24 4H 2 O and C 16 h 22 N 4 o 3 Add it into a beaker filled with deionized water, place it in a constant temperature water bath at 50°C and stir until the solids are completely dissolved, and continue stirring until the solution is colorless; then add the weighed WC-Co powder and magnetic rotor into the beaker, and then add The beaker was heated in a magnetic stirrer, and the heating temperature was set to 120°C. After the water in the solution...

Embodiment 2

[0061] WC-Co-Y prepared in this example 2 o 3 -Y in Mo cemented carbide 2 o 3 1.0 wt%, Mo 3.5 wt%, and WC-Co 95.5 wt%.

[0062] The preparation process is as follows: first according to the Y in the cemented carbide 2 o 3 The content of , Mo and WC-Co is calculated according to formula (1) and formula (2) Y(NO 3 ) 3 ·6H 2 O, (NH 4 ) 6 Mo 7 o 24 4H 2 The amount of O and WC-Co should be weighed according to the calculated amount.

[0063] 1. Preparing the precursor: the weighed Y(NO 3 ) 3 ·6H 2 O, (NH 4 ) 6 Mo 7 o 24 4H 2 O and C 16 h 22 N 4 o 3 Add it into a beaker filled with deionized water, place it in a constant temperature water bath at 50°C and stir until the solids are completely dissolved, and continue stirring until the solution is colorless; then add the weighed WC-Co powder and magnetic rotor into the beaker, and then add The beaker was heated in a magnetic stirrer, and the heating temperature was set at 130°C. After the water in the solution...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fracture toughness | aaaaa | aaaaa |

| Fracture toughness | aaaaa | aaaaa |

| Fracture toughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com