Preparation method of superfine palladium powder

A technology of ultra-fine palladium powder and palladium black, applied in metal processing equipment, nanotechnology, transportation and packaging, etc., to achieve the effects of high product yield, easy industrial production, and reduced introduction of impurities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

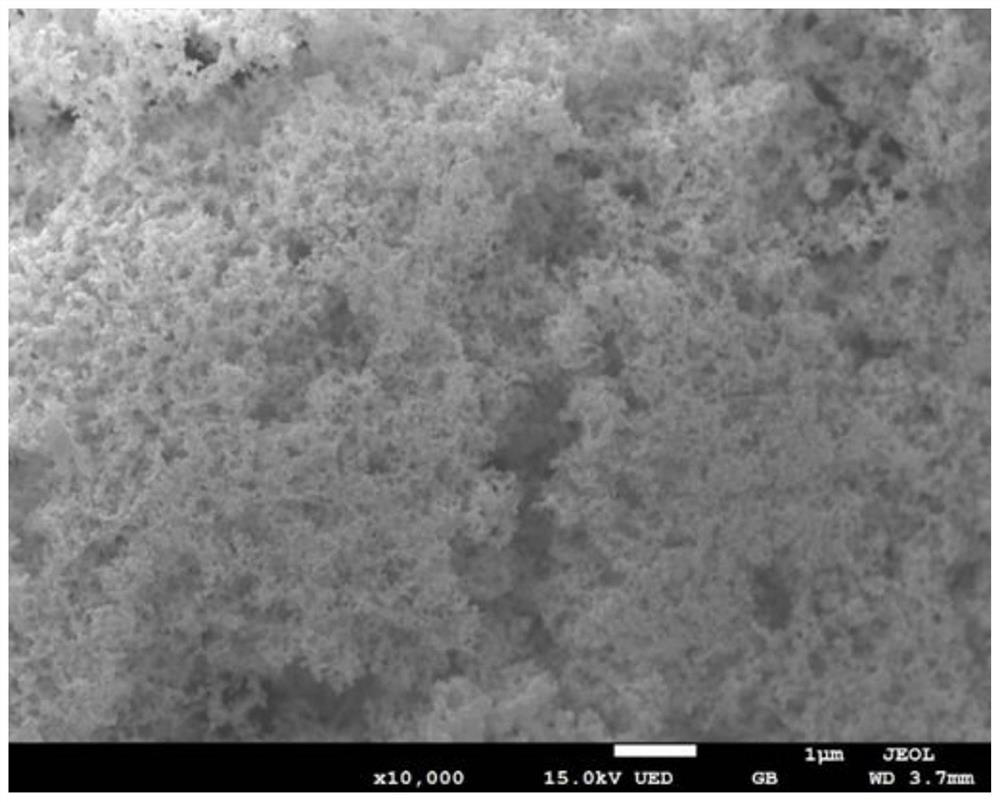

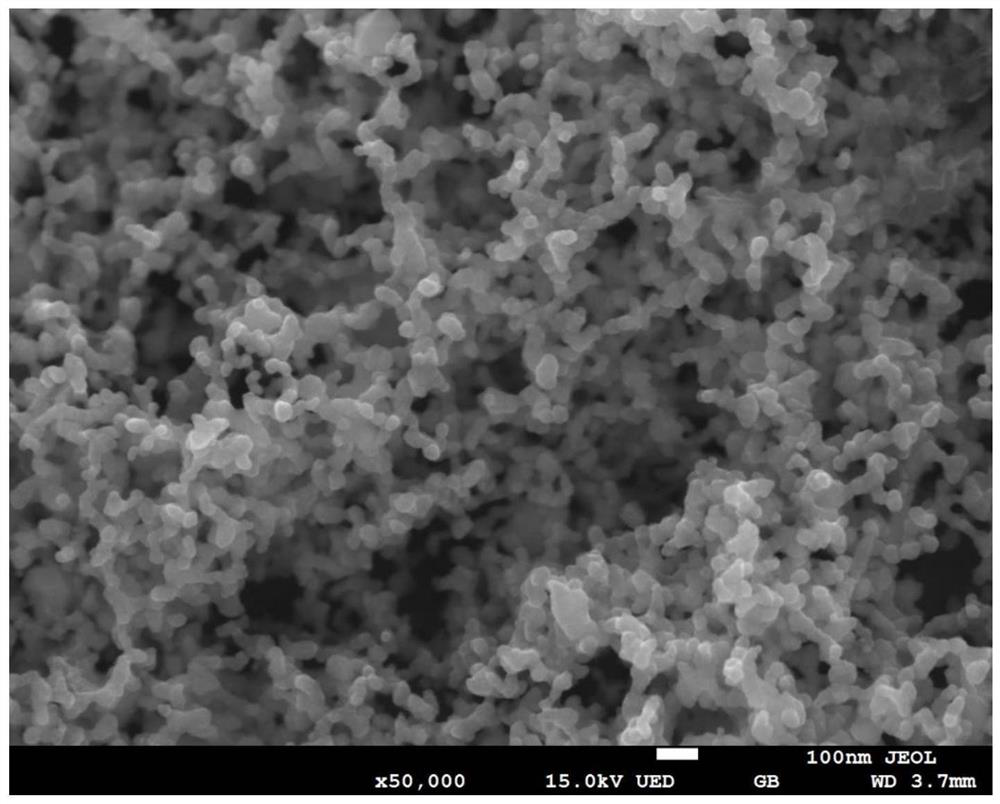

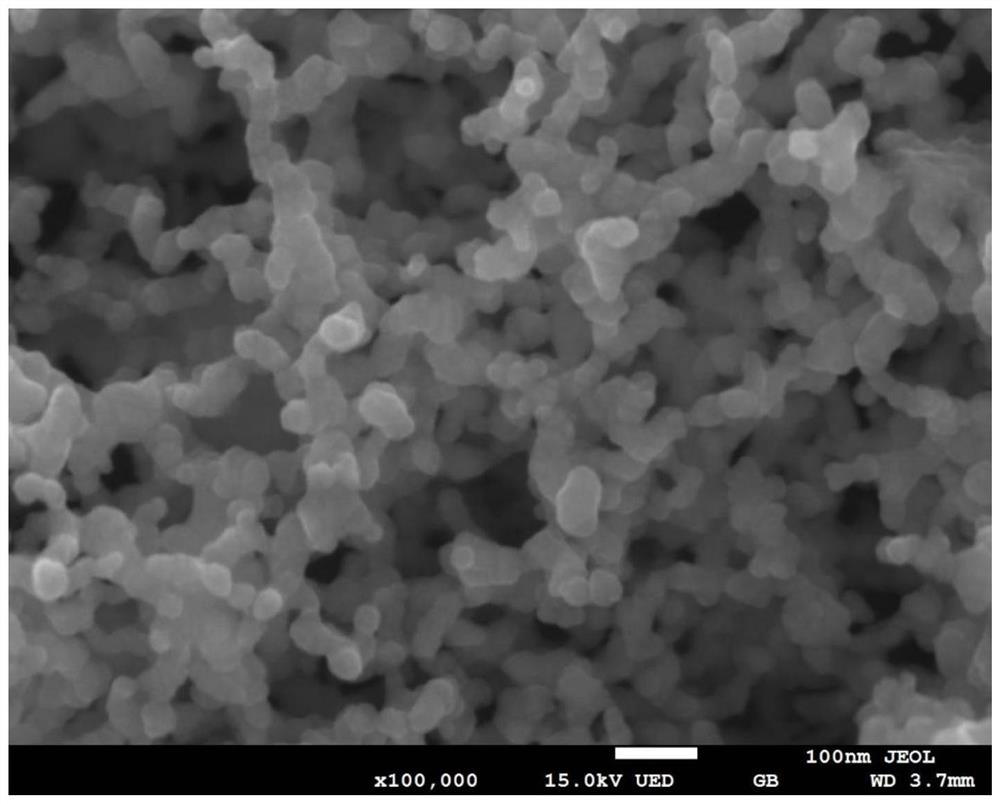

Image

Examples

Embodiment 1

[0019] Embodiment 1: a kind of preparation method of superfine palladium powder, concrete steps are as follows:

[0020] (1) Dissolve the palladium precursor (10mg palladium chloride) in hydrochloric acid-deionized water at a temperature of 25°C under stirring conditions to obtain a palladium precursor solution; wherein the palladium precursor solution in the palladium precursor solution (palladium chloride) The concentration is 0.005mol / L; the concentration of hydrochloric acid-hydrochloric acid in deionized water is 0.055mol / L;

[0021] (2) The palladium precursor solution is added dropwise in the glycerol, and the constant temperature reaction 10min obtains the palladium black solution at a stirring rate of 80°C and 500rpm at a temperature of 80°C; wherein the volume ratio of the palladium precursor solution to the glycerin is 1: 4;

[0022] (3) Aging the palladium black solution for 10 minutes, centrifuging the solid and liquid, removing the supernatant, washing the solid...

Embodiment 2

[0024] Embodiment 2: a kind of preparation method of superfine palladium powder, concrete steps are as follows:

[0025] (1) Under stirring conditions at a temperature of 25° C., the palladium precursor (10 mg palladium nitrate) is dissolved in hydrochloric acid-deionized water to obtain a palladium precursor solution; wherein the concentration of the palladium precursor (palladium nitrate) in the palladium precursor solution is 0.010mol / L; hydrochloric acid-hydrochloric acid concentration in deionized water is 0.085mol / L;

[0026] (2) The palladium precursor solution is added dropwise in the glycerol, and the constant temperature reaction 15min obtains the palladium black solution at a stirring rate of 120°C and 500rpm at a temperature of 120°C; wherein the volume ratio of the palladium precursor solution to the glycerol is 1: 2;

[0027] (3) Aging the palladium black solution for 15 minutes, centrifuging the solid and liquid, removing the supernatant, washing the solid with...

Embodiment 3

[0029] Embodiment 3: a kind of preparation method of superfine palladium powder, concrete steps are as follows:

[0030] (1) Dissolve the palladium precursor (10 mg palladium acetylacetonate) in hydrochloric acid-deionized water under stirring conditions at a temperature of 25° C. to obtain a palladium precursor solution; wherein the palladium precursor solution (palladium acetylacetonate) The concentration is 0.012mol / L; the concentration of hydrochloric acid-hydrochloric acid in deionized water is 0.175mol / L;

[0031] (2) The palladium precursor solution is added dropwise in the glycerol, and the constant temperature reaction 20min obtains the palladium black solution at a temperature of 160° C. and a stirring rate of 500 rpm; wherein the volume ratio of the palladium precursor solution to the glycerol is 1: 3;

[0032] (3) Aging the palladium black solution for 20 minutes, centrifuging the solid and liquid, removing the supernatant, washing the solid with deionized water a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com