Alkali corrosion auxiliary agent for cleaning wound-plated polycrystalline silicon and application of alkali corrosion auxiliary agent

A polysilicon, alkali corrosion technology, applied in the direction of surface etching composition, sustainable manufacturing/processing, electrical components, etc., can solve the problems of product yield decline, low yield, damage nitrogen content, etc., and achieve extended corrosion The effect of poor speed, improving product yield and reducing chemical cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] The invention provides an alkali corrosion auxiliary agent for cleaning and plating polysilicon. The mass percent content of each component is: 2% to 5% polyether, 1% to 2.5% anionic surfactant, 1% to 2.5% % dispersant, the balance is deionized water; specifically:

[0043] The polyether is selected from one or more of polyperfluoromethyl isopropyl ether, polyoxyethylene nonylphenol phosphate, polyether modified silicone oil;

[0044] The anionic surfactant is selected from one or more of sodium dodecylbenzene sulfonate, sodium cocoyl methyl taurate, and sodium α-alkenyl sulfonate;

[0045] The dispersant is selected from one or more of sodium lignosulfonate, 2-naphthalenesulfonic acid and sodium polyacrylate.

Embodiment 2

[0047] The present invention also provides an alkaline etching solution for cleaning polysilicon around and plating, which contains an alkaline solution and the alkaline corrosion auxiliary agent of Example 1, the mass ratio of the alkaline corrosion auxiliary agent to the alkaline solution is 2.5 to 5:100, and the The alkali solution is a KOH solution or a NaOH solution; the mass percentage of KOH in the KOH solution is 0.5%-1.5%; the mass percentage of NaOH in the NaOH solution is 0.5%-1.5%.

Embodiment 3

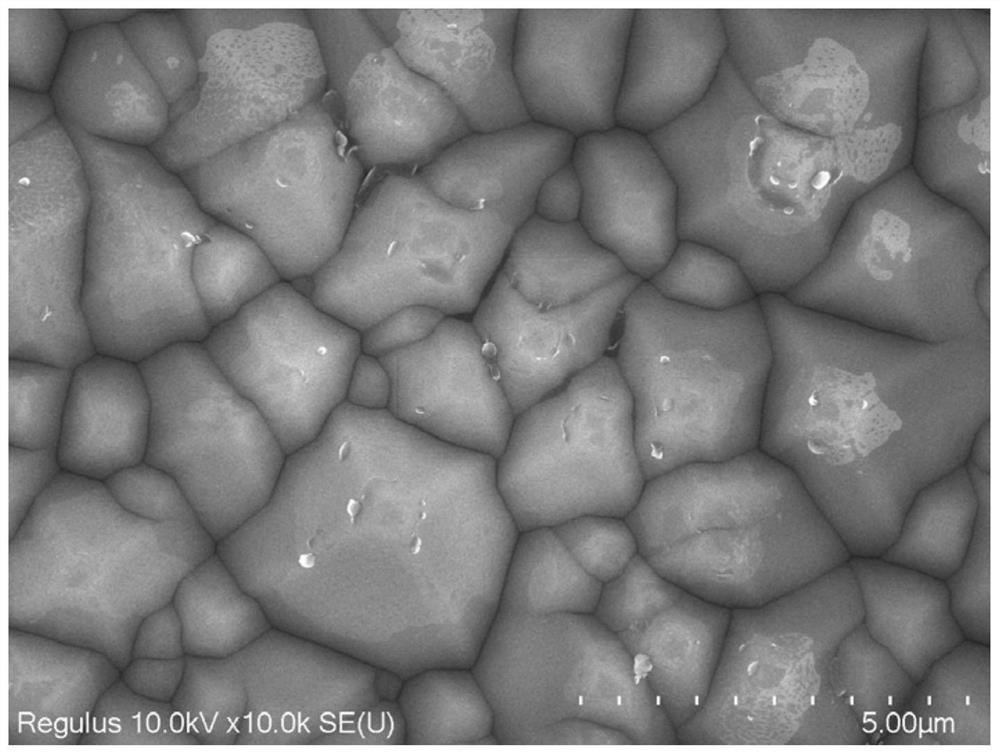

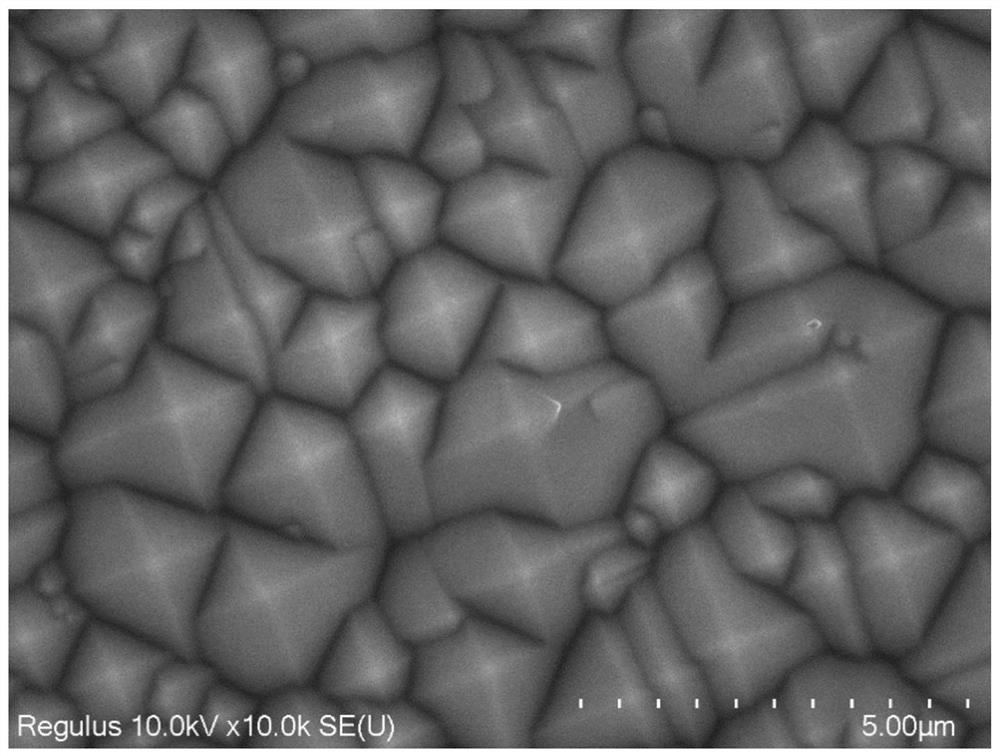

[0049] The present invention also provides a method for cleaning polycrystalline silicon wrapping. The silicon chip is immersed in the alkali etching solution of the embodiment 2 for 150-250 seconds, and the temperature of the alkali etching solution is controlled at 80-88°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com