Antistatic optical-grade hydrophobic material and preparation method thereof

A hydrophobic material, optical-grade technology, used in chemical instruments and methods, lamination, layered products, etc., can solve the problem of poor formation of internal components of antistatic materials, peeling of nano-silica dispersion, and easy to be scratched and other problems, to achieve the effect of avoiding peeling failure, good tensile strength, and not easy to color.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

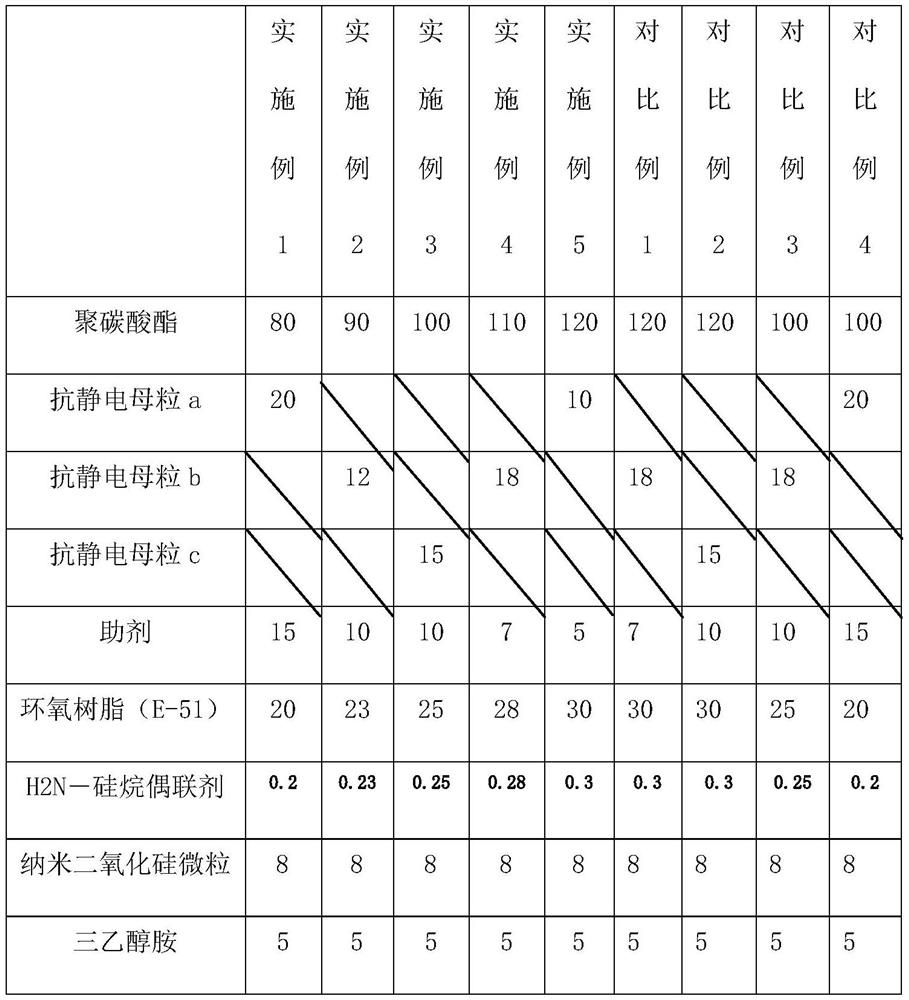

Embodiment 1

[0028] This embodiment provides an antistatic optical grade hydrophobic material, comprising:

[0029] a base layer and a hydrophobic functional layer, the hydrophobic functional layer is arranged on one side or both sides of the base layer through a thermoplastic adhesive;

[0030] The base layer includes the following raw material components in parts by weight:

[0031] 80-120 parts of the first resin matrix,

[0032] Antistatic masterbatch 10-20 parts,

[0033] 5-15 parts of additives;

[0034] The hydrophobic functional layer includes the following raw material components in parts by weight:

[0035] 20-30 parts of the second resin matrix,

[0036] 8 parts of nano-silica particles,

[0037] The silane coupling agent component is 1% of the second resin matrix component,

[0038] 5 parts of curing agent.

[0039] Wherein, preferably, the first resin matrix is polycarbonate;

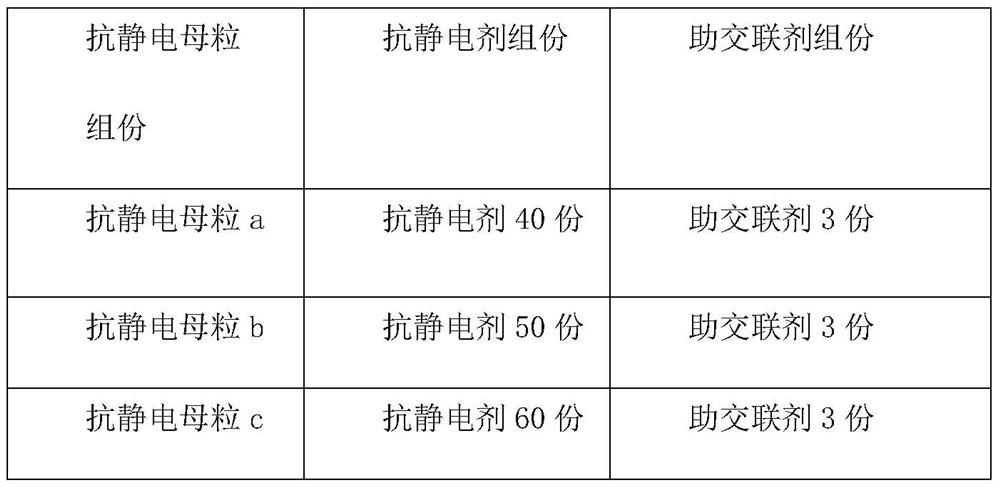

[0040] The antistatic master batch includes the following raw material components in parts...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com