High-activity selective perovskite type photo-thermal catalyst as well as preparation method and application thereof

A selective, perovskite-type technology, applied in the direction of catalyst activation/preparation, catalysts, carbon compound catalysts, etc., can solve the problems of low catalytic efficiency and unfavorable catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

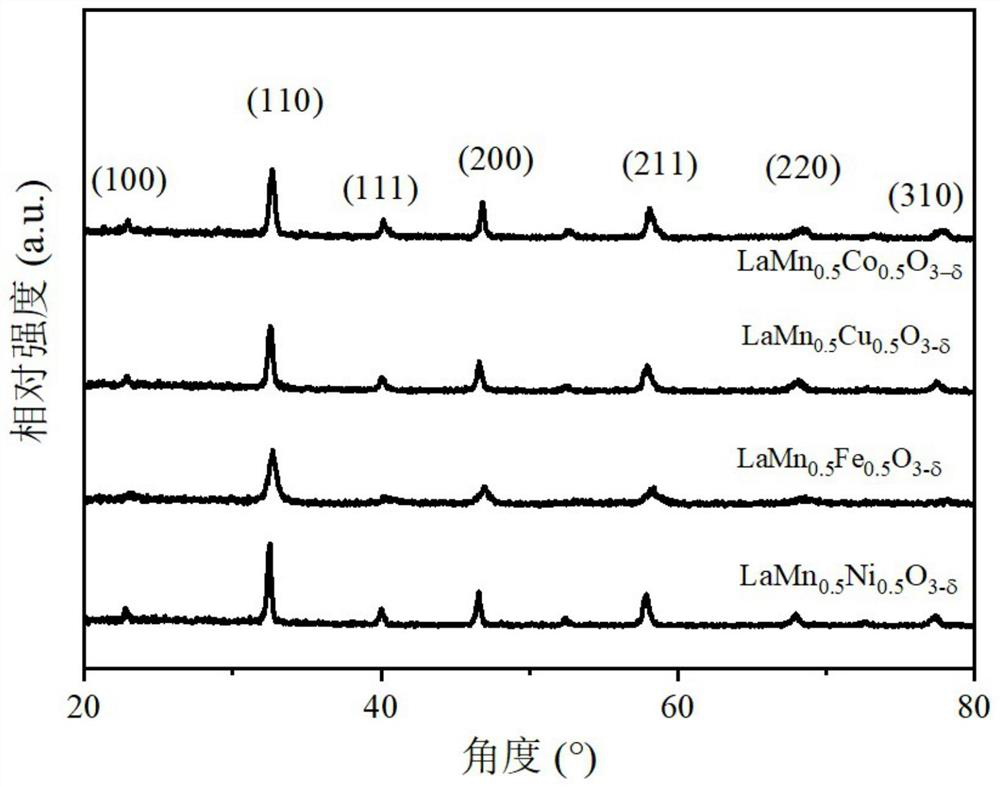

Embodiment 1

[0025] A highly active and selective LaMn 0.5 Ni 0.5 o 3-δ The preparation method of photothermal catalyst comprises the following steps:

[0026] Step S1: 0.03mol of La(NO 3 ) 3 ·6H 2 O, 0.015mol of Mn(NO 3 ) 3 4H 2 O and 0.015mol Ni(NO 3 ) 3 ·6H 2 O mixed, added to 60mL deionized water;

[0027] Step S2: Add 0.072 mol of citric acid monohydrate according to the molar ratio of the total amount of nitrate and citric acid of 1:1.2 and mix evenly;

[0028] Step S3: heating and stirring the mixed solution in a water bath at 80°C until a sol is formed;

[0029] Step S4: Transfer to an oven and keep drying at 170°C, take it out and grind it into powder with a mortar;

[0030] Step S5: heat preservation at a calcination temperature of 700° C. for 7 hours, take out and grind to obtain a perovskite nano-powder.

Embodiment 2

[0032] A highly active and selective LaMn 0.5 co 0.5 o 3-δ The preparation method of photothermal catalyst comprises the following steps:

[0033] Step S1: 0.03mol of La(NO 3 ) 3 ·6H 2 O, 0.015mol of Mn(NO 3 ) 3 4H 2 O and 0.015mol of Co(NO 3 ) 3 ·6H 2 O mixed, added to 60mL deionized water;

[0034] Step S2: Add 0.072 mol of citric acid monohydrate according to the molar ratio of the total amount of nitrate and citric acid of 1:1.2 and mix well;

[0035] Step S3: heating and stirring the mixed solution in a water bath at 80°C until a sol is formed;

[0036] Step S4: Transfer to an oven and keep drying at 170°C, take it out and grind it into powder with a mortar;

[0037] Step S5: heat preservation at a calcination temperature of 700° C. for 7 hours, and obtain a perovskite nano-powder after taking it out.

Embodiment 3

[0039] A highly active and selective LaMn 0.5 Cu 0.5 o 3-δ The preparation method of photothermal catalyst comprises the following steps:

[0040] Step S1: 0.03mol of La(NO 3 ) 3 ·6H 2 O, 0.015mol of Mn(NO 3 ) 3 4H 2 O and 0.015mol of Cu(NO 3 ) 2 ·3H 2 O mixed and mixed, added to 60mL deionized water;

[0041] Step S2: Add 0.072 mol of citric acid monohydrate according to the molar ratio of the total amount of nitrate and citric acid of 1:1.2 and mix well;

[0042] Step S3: heating and stirring in a water bath at 80°C until a sol is formed;

[0043] Step S4: Transfer to an oven and keep drying at 170°C, take it out and grind it into powder with a mortar;

[0044] Step S5: heat preservation at a calcination temperature of 700° C. for 7 hours, and obtain a perovskite nano-powder after taking it out.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com