Surface zwitterionic polymer modified magnetic microsphere as well as preparation method and application of magnetic microsphere

A technology of magnetic microspheres and zwitterions, which is applied in the fields of alkali metal compounds, chemical instruments and methods, and other chemical processes, and can solve the problems of reduced sensitivity of magnetic microspheres, dim prospects for industrialization, and complex distillation, precipitation, and polymerization devices.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

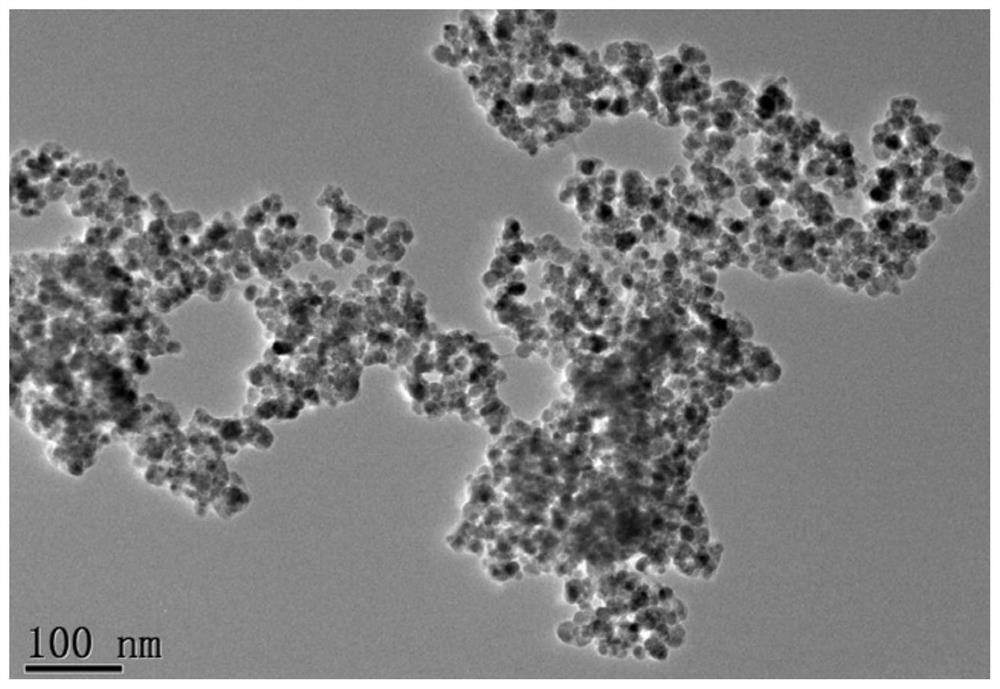

[0040] (1) Preparation of magnetic fluid: Weigh 20g of ferrous sulfate and dissolve it in 100ml of ultrapure water, heat up to 70°C, add 10ml of ammonia water, add 5ml of oleic acid after mechanical stirring for 10 minutes, continue stirring for 30min, then heat up to 80°C, After heat preservation for 1 hour, turn off the heating, cool to room temperature, purify, wash with water and methanol, and then dry to obtain oleic acid-modified ferric oxide. The ferroferric oxide modified by oleic acid is uniformly dispersed with chloroform to prepare a magnetic fluid, and the magnetic fluid with a mass concentration of 50% is obtained. figure 1 It is the morphology under the magnetic fluid transmission microscope.

[0041](2) Preparation of submicron magnetic microspheres: accurately weigh 100 mg sodium lauryl sulfate and disperse it in 50 ml ultrapure water, take 2 ml of the magnetic fluid in step (1) and disperse it in the SDS aqueous solution, and use a cell disruptor 200W Sonicat...

Embodiment 2

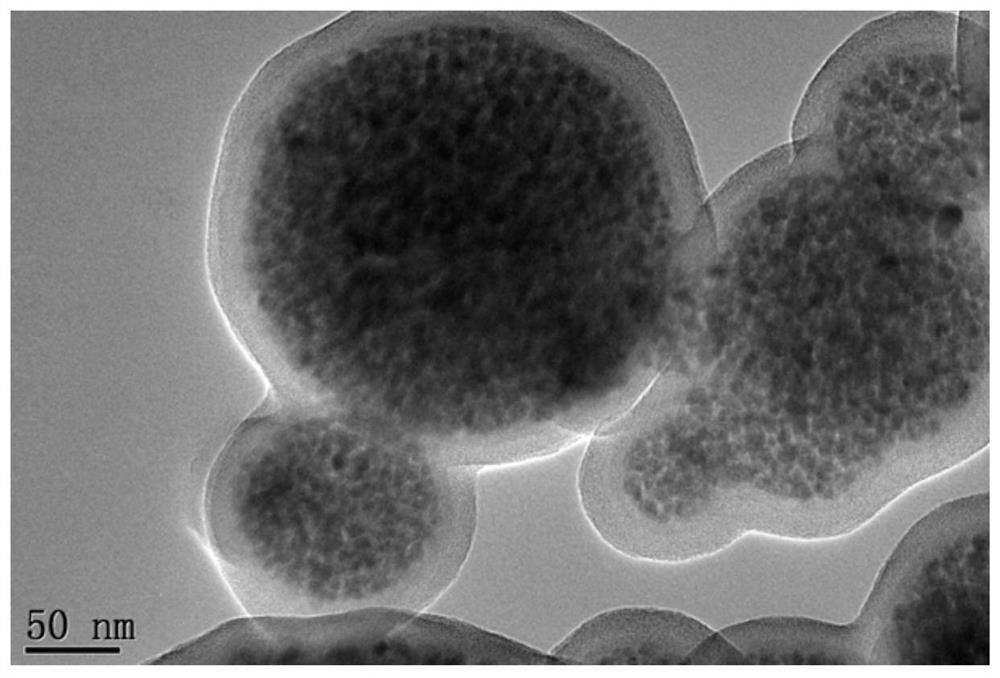

[0049] (1) Preparation of zwitterion-coated magnetic microspheres: Accurately weigh 100mg of poly(4-styrenesulfonic acid-copolymerization-maleic acid-sodium salt) and add it to 100ml of acetonitrile, add 100mg of the Silicon-coated magnetic microspheres, 100 μl methacrylic acid, 100 mg N,N'-methylenebisacrylamide, 10 mg ethylene glycol methacrylate, 2.5 mg azobisisobutyronitrile, high-purity nitrogen and continue After stirring for 30 minutes, start heating to 90° C., continue to stir and react for 2 hours, then purify, wash with ethanol and disperse into water to obtain zwitterion-modified magnetic microspheres.

[0050] (2) Magnetic microglobulin coupling: Disperse 10 mg of magnetic microspheres in step 4 into 500 μl pH 6.0 MES buffer, mix well, and then magnetically separate once, discard the supernatant, continue to add 400 μl pH 6.0 MES buffer, and add 100 μl EDC Solution, 40ug NT-proBNP antibody, incubated at 37°C for 30 minutes, then magnetically separated, discarded th...

Embodiment 3

[0053] (1) Preparation of magnetic fluid: Weigh 12g of ferrous sulfate heptahydrate and 20g of ferric chloride hexahydrate, dissolve them in 100ml of ultrapure water, heat up to 65°C, add 10ml of ammonia water, stir mechanically for 10 minutes, then add 5ml of oil acid, continue to stir for 30 minutes, then raise the temperature to 80°C, keep warm for 1 hour, turn off the heating, cool to room temperature, purify, wash with water and methanol, and dry to obtain oleic acid-modified ferric oxide. The magnetic fluid was prepared by uniformly dispersing the oleic acid-modified iron ferric oxide with chloroform to obtain a magnetic fluid with a mass concentration of 60%.

[0054] (2) Preparation of submicron magnetic microspheres: Accurately weigh 20 μl tween20 and disperse it into 50 ml ultrapure water, take 2 ml of the magnetic fluid in step (1) and disperse it into the SDS aqueous solution, and use a cell disruptor 200W to sonicate for 10 minutes to obtain the mass Concentration...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Sensitivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com