A kind of heavy metal wastewater treatment method

A technology for wastewater treatment and heavy metals, applied in water/sewage treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc. Stability, large stirring power consumption, etc., to achieve good reactivity and reusability, improve reusability, and reduce reaction energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

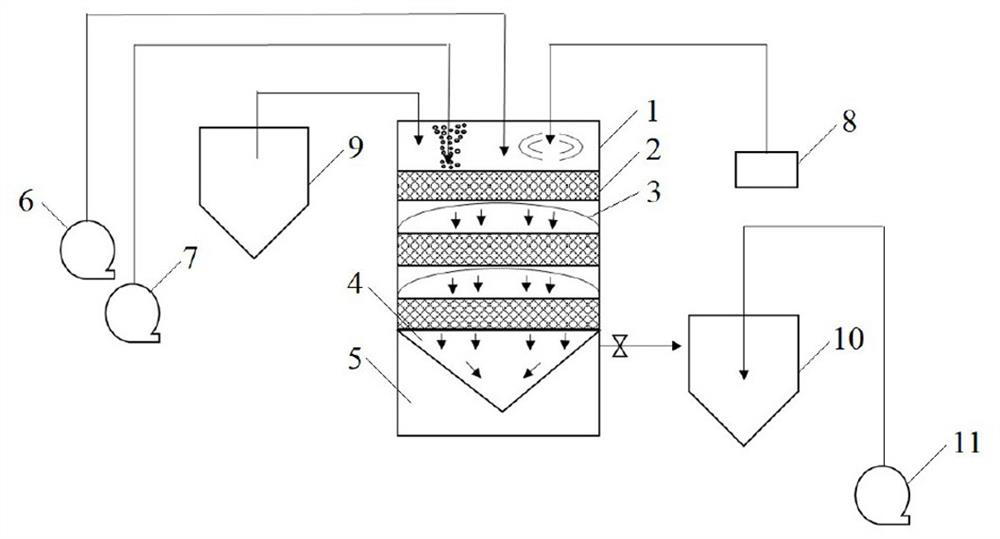

[0047] Such as figure 1 As shown, this embodiment provides a heavy metal wastewater treatment reactor, the reactor has a shell 1, a packing area and a sedimentation area are arranged inside the shell 1, and the packing area includes at least two packing layers 2 arranged at intervals up and down, The settling zone is set below the filling zone.

[0048] The reactor shell 1 can be set in a cylindrical shape, and at this time, its cross-sectional shape is circular. There is no strict limit on the number of stages for the packing layer 2 in the housing 1, and it can be set to 2-4 stages, and the packing layer 2 can be a sponge layer. An arc top 3 is arranged between adjacent packing layers 2, and its cross-sectional shape is a circular arc. The central angle of the arc is 90-120°, and the chord length is the diameter of the shell 1; A plurality of through holes, the diameter of the through holes is 0.4-0.6mm. In this embodiment, the height of the filling area is set to 1 / 3 to ...

Embodiment 2

[0053] In this embodiment, the heavy metal wastewater treatment reactor of Example 1 is used for treatment, and a small reactor for treating 1.25 L of heavy metal wastewater per hour is taken as an example for illustration.

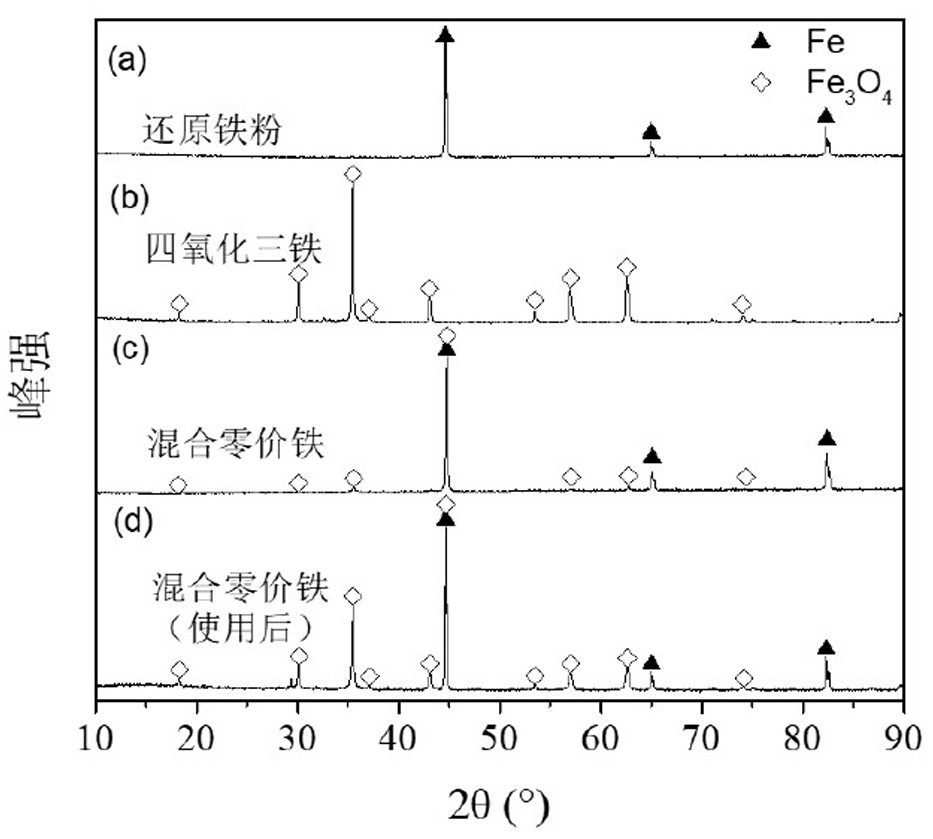

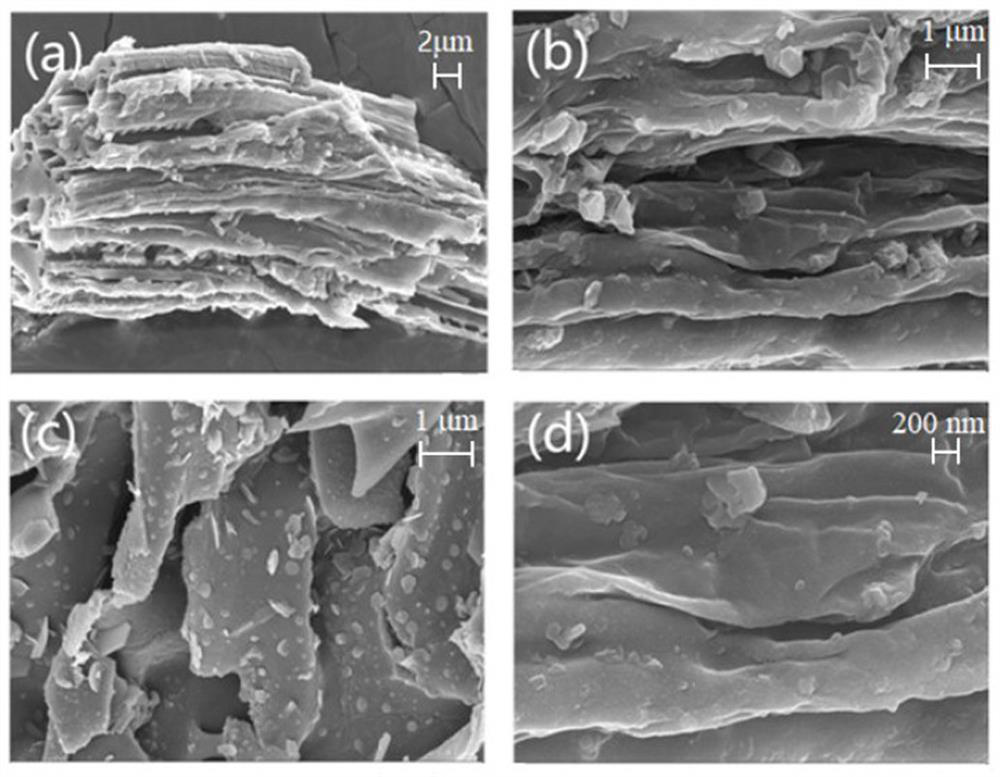

[0054] 1. Filler activation

[0055] 100 g of biochar and 100 g of iron powder were filled into the packing layer of the reactor, and NaNO was continuously added dropwise to the upper part of the reactor at a rate of 12 mL / h. 3 with FeSO 4 Mixed solution, NaNO in mixed solution 3 , FeSO 4 The concentration of both was 30mg / L, and the continuous dropwise addition was continued for 24 hours to prepare the activated zero-valent iron mixed material.

[0056] 2. Prepare simulated heavy metal mixed solution

[0057] Prepare a simulated heavy metal mixed solution containing copper, manganese, arsenic, selenium, lead, cadmium, mercury, and chromium ions: pipette 4 mL of 1000 mg / L copper standard stock solution, 20 mL of 1000 mg / L manganese standard stock solu...

Embodiment 3

[0064] The treatment method of the present embodiment is with reference to embodiment 2, and wherein simulated heavy metal mixed solution copper ion initial concentration is 4mg / L, and manganese ion initial concentration is 20 mg / L, and arsenic, selenium, lead, cadmium, mercury and chromium ion initial concentration are all It is 2 mg / L.

[0065] The simulated heavy metal mixed solution was continuously pumped into the upper part of the reactor at a rate of 7.5 L / h, 3.75 L / h and 1.25 L / h, and FeSO was continuously added dropwise to the reactor at a rate of 12 mL / h. 4 and FeCl 3 The mixed solution, FeSO in the mixed solution 4 , FeCl 3 The concentration is 30mg / L.

[0066] Samples were taken from the lower part of the reactor at regular intervals, and the concentration of metal ions in the filtrate was detected.

[0067] Table 1 The detected concentration of each pollutant in the effluent of the reactor at different hydraulic retention times

[0068]

[0069] The result...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com