A carbon-based bioanode, its preparation method and microbial fuel cell

A bioanode and fuel cell technology, applied in biochemical fuel cells, battery electrodes, circuits, etc., can solve the problems of less attachment sites and limited electrochemical activity on the surface of electrode materials, and achieve cost-effective, good biocompatibility, The effect of good conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

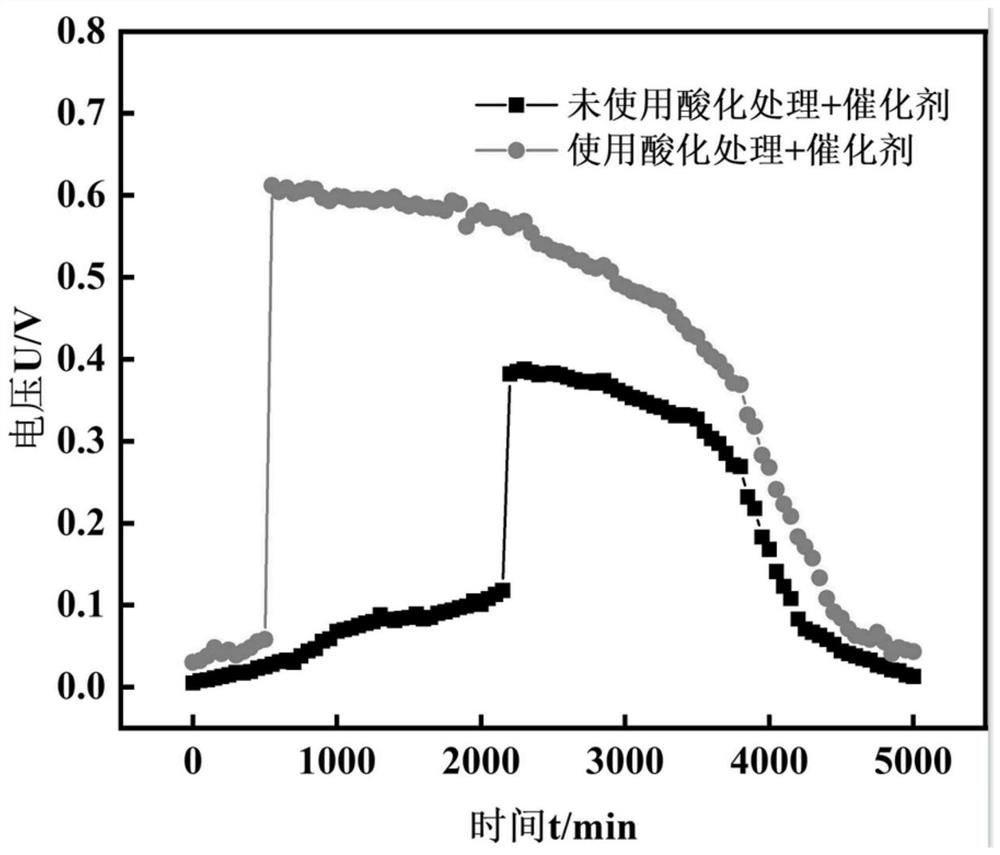

[0032] A method for preparing a carbon-based bioanode, comprising the steps of:

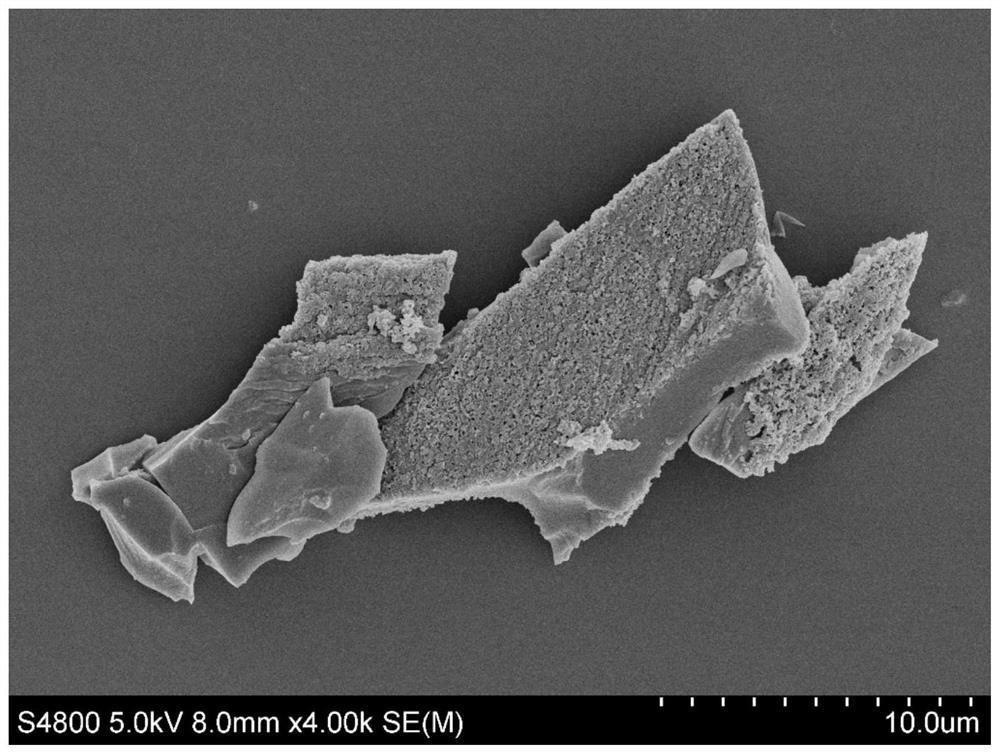

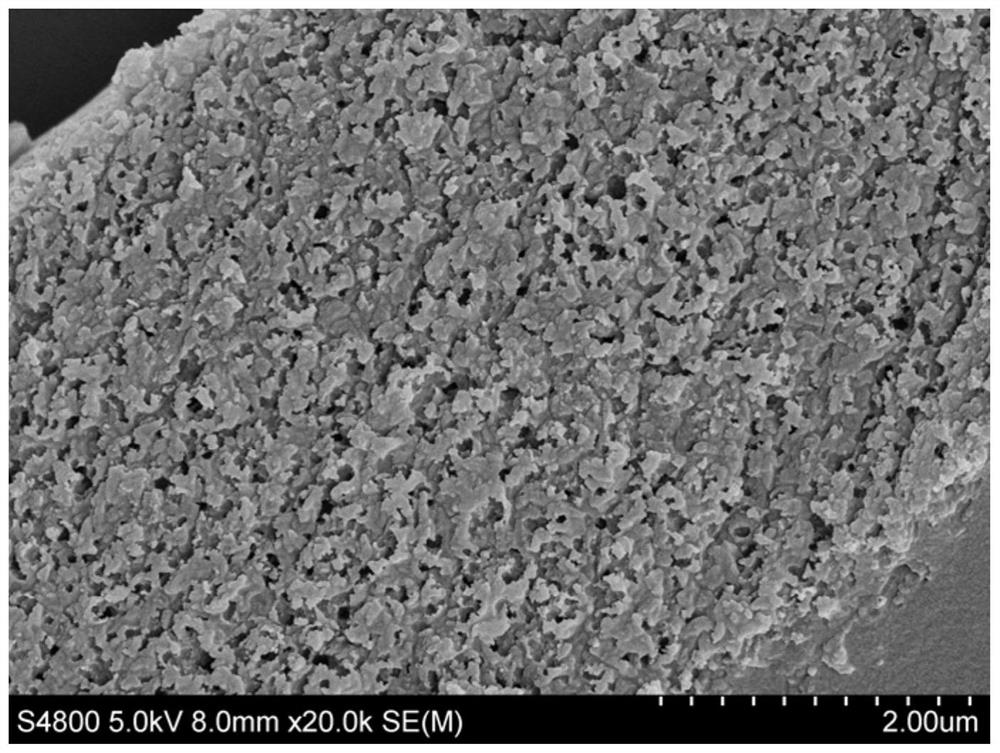

[0033] (1) Knead and clean the sisal fibers and cut them into 1-2cm long segments, then acidify the chopped sisal fiber segments with a hydrochloric acid solution with a concentration of 10wt%, and then acidify the sisal fibers after acidification The hemp fiber is washed, dried and set aside;

[0034] (2) Mix the acidified sisal fiber with a certain amount of ferric oxide and grind it with a ball mill for 1 hour, wherein the mass of ferric oxide accounts for 15wt% of the mass of the sisal fiber; the ground mixture is After washing and drying, put it into a tube furnace for carbonization under an inert atmosphere for 2 hours. The carbonization temperature is 900°C, and the heating rate is 3°C / min. After the furnace temperature is cooled to room temperature, pass through a 200-mesh sieve to obtain a fibrous carbon material;

[0035] (3) Dissolve the iron-containing substances in the fibrous carbo...

Embodiment 2

[0044] A method for preparing a carbon-based bioanode, comprising the steps of:

[0045] (1) Knead and wash the sisal fiber and cut it into 1-2cm long sections, then acidify the chopped sisal fiber section with a hydrochloric acid solution with a concentration of 5wt%, and then acidify the sisal fiber The hemp fiber is washed, dried and set aside;

[0046] (2) Mix the acidified sisal fiber with a certain amount of ferrous oxide and grind it with a ball mill for 1 hour, wherein the mass of ferrous oxide accounts for 18wt% of the mass of the sisal fiber; the ground mixture is washed and dried After treatment, put it into a tube furnace for carbonization under an inert atmosphere for 2 hours, the carbonization temperature is 1200°C, and the heating rate is 4°C / min. After the furnace temperature is cooled to room temperature, pass through a 200-mesh sieve to obtain a fibrous carbon material;

[0047] (3) Dissolve the iron-containing substances in the fibrous carbon material obtai...

Embodiment 3

[0056] A method for preparing a carbon-based bioanode, comprising the steps of:

[0057] (1) Knead and wash the sisal fiber and cut it into 1-2cm long sections, then acidify the chopped sisal fiber section with a hydrochloric acid solution with a concentration of 5wt%, and then acidify the sisal fiber The hemp fiber is washed, dried and set aside;

[0058] (2) Mix the acidified sisal fiber with a certain quality of ferroferric oxide and grind it for 2 hours with a ball mill, wherein the mass of ferric oxide accounts for 18wt% of the mass of the sisal fiber; the ground mixture is After washing and drying, put it into a tube furnace for carbonization for 2.5 hours under an inert atmosphere. The carbonization temperature is 700°C, and the heating rate is 3°C / min. After the furnace temperature is cooled to room temperature, pass through a 200-mesh sieve to obtain fibrous carbon materials ;

[0059] (3) Dissolve the iron-containing substances in the fibrous carbon material obtain...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com