A Clean Dyeing Process of Blended Textiles

A textile and cleaning technology, applied in the field of dyeing technology, can solve the problems of uneven dyeing, difficult wastewater treatment, dyeing uniformity and poor speed, etc., achieve uniform dyeing, improve dyeing effect and uniformity of dyeing, and prolong contact time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

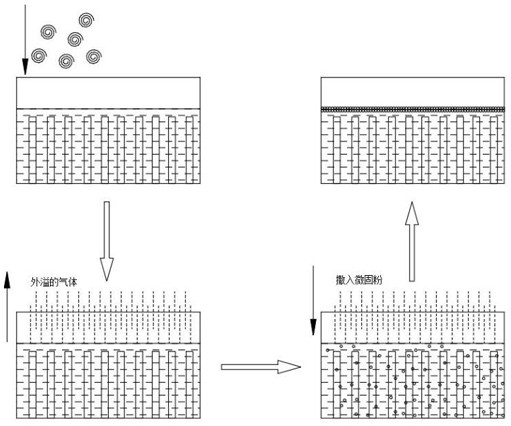

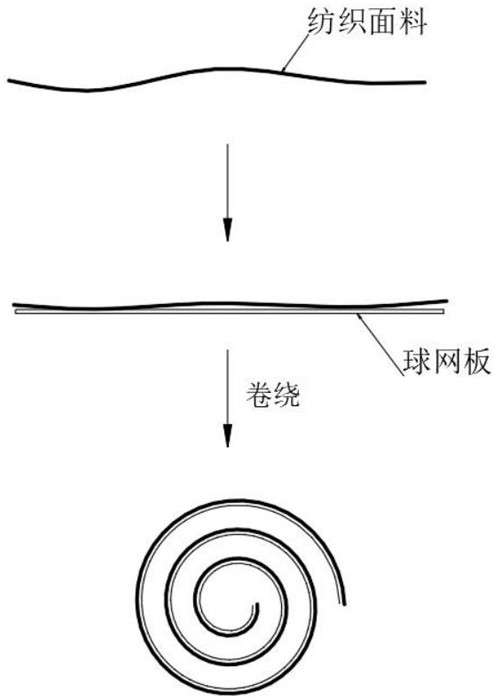

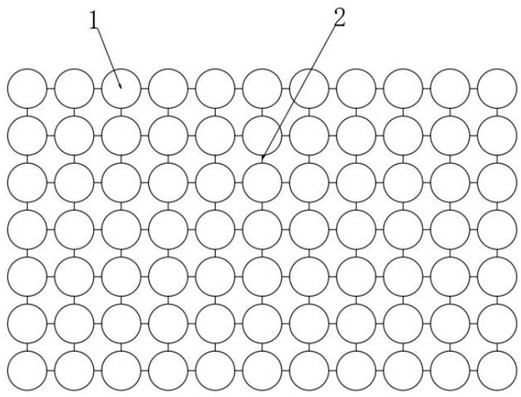

[0040] see figure 1 , a clean dyeing process for blended textiles, on the basis of existing technologies, such as figure 2, so that the textile fabric is dyed in rolls on the ball net, under the action of the dyeing liquid, the ball net overflows gas, interspersed between the textile fabrics and overflows upwards, speeding up the diffusion speed of the dyeing liquid near the textile fabric into the cloth, and then As the soaking time prolongs, the externally moving floating ball 4 in the ball net overflows and floats up, driving the textile fabric to move slightly during the upfloating process, further speeding up the dyeing speed, and then sprinkles micro-solid powder into the dyeing pool to make the dyeing liquid appear viscous. Thickness, reducing the fluidity of the dyeing solution, and effectively locking the dye molecules on the textile fabric, and then standing for 0.5-2h, assisting the attachment of the dyeing molecules on the textile fabric, compared with Figure 10...

Embodiment 2

[0046] like Figure 8 , the textile fabric is pretreated before rolling, and the pretreatment includes the following steps:

[0047] First, spray water mist on the surface of the textile fabric to make it wet, and then spray hydrophilic salt powder on the surface, so that the hydrophilic salt powder forms a layer of color-attracting layer on the surface. The hydrophilic salt powder is mixed with chloride Sodium starch powder, and the volume ratio of sodium chloride to starch powder is 1:2-5. Sodium chloride can effectively assist dyeing molecules in coloring textile fabrics, and effectively alleviate the dyeing of blended fabrics due to the presence of polyester. It leads to the problem of slow coloring and poor effect. In addition, through the setting of the color-attracting layer, due to the rolled fabric, the fabrics form a barrier between each other. After the color layer is dissolved in water, such as Figure 9 , so that the fluidity of the dyeing solution near the fabri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com