Cleaning production process in dyeing and printing industry

A clean production and industry technology, applied in dyeing method, textile industry wastewater treatment, water/sludge/sewage treatment, etc., can solve the problems of complex water quality, difficult treatment, large wastewater discharge, etc., to reduce pollution and shorten the Dyeing time, effect of reducing emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in conjunction with the accompanying drawings and specific embodiments.

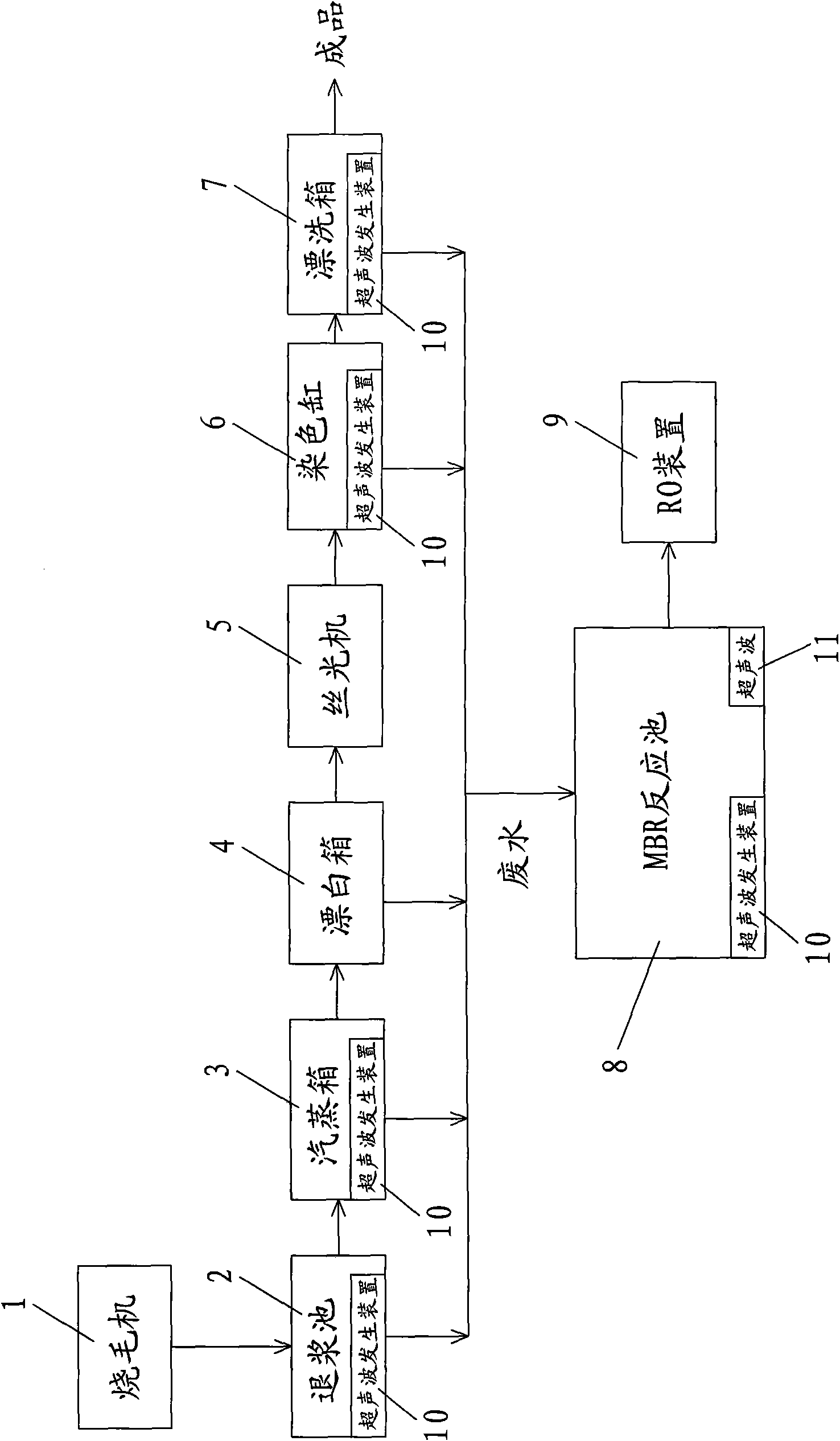

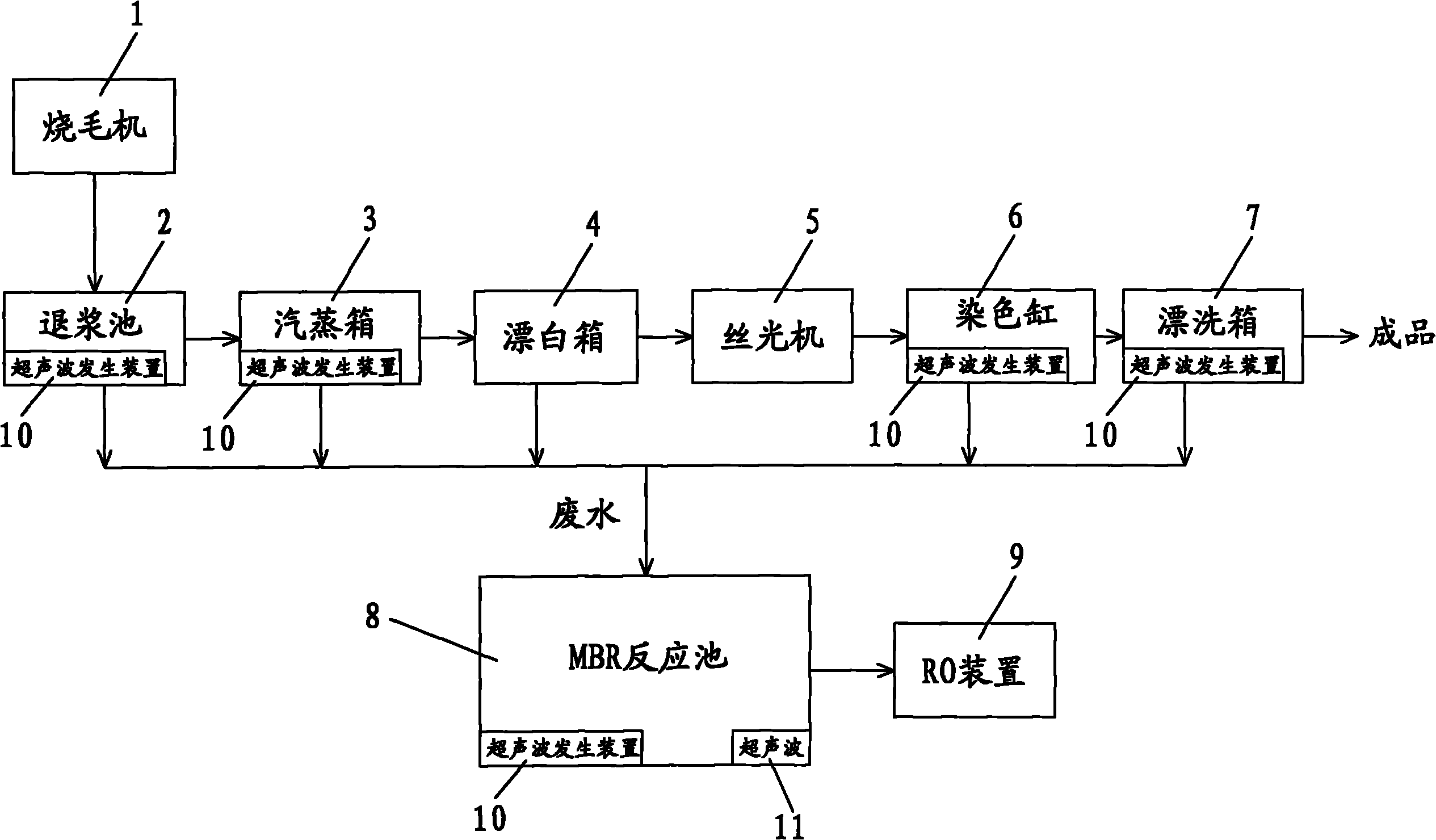

[0022] A clean production process in the printing and dyeing industry, including singeing - desizing - scouring - bleaching - mercerizing - dyeing / printing - finishing (rinsing) - finished product process and wastewater treatment process, wherein,

[0023] In the process of desizing and scouring, use 20-50KHZ ultrasonic irradiation at room temperature, and in the dyeing / printing process, use 20-50KHZ ultrasonic irradiation on the fabric soaked in dye solution; after the fabric is dyed, it needs to Rinse to remove undyed, unfixed or hydrolyzed dyes. In the finishing (rinsing) process, use 20-50KHZ ultrasonic waves in the rinsing box to irradiate to promote the washing effect. The printing and dyeing wastewater produced in the desizing, scouring, bleaching, dyeing / printing and finishing processes is irradiated with 20-50KHz ultrasonic waves before the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com