Cashmere-like yarn dyeing method and cashmere-like yarn dye vat

A technique of imitating cashmere yarn and dyeing method, which is applied in the processing of textile materials, continuous processing of textile materials, liquid/gas/steam yarn/filament processing, etc. Easy to assemble and disassemble without problems such as laborious operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

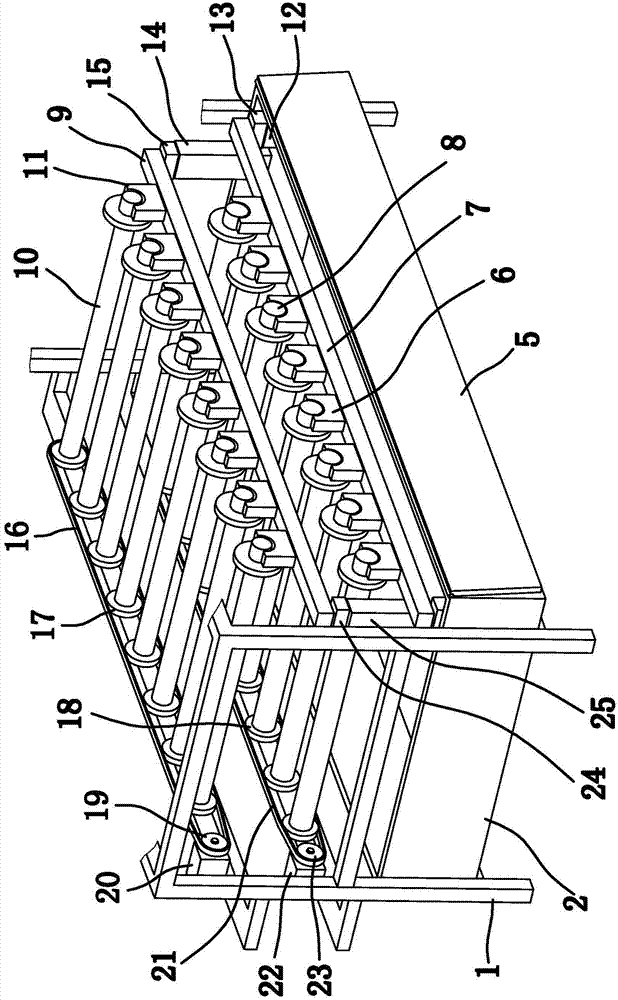

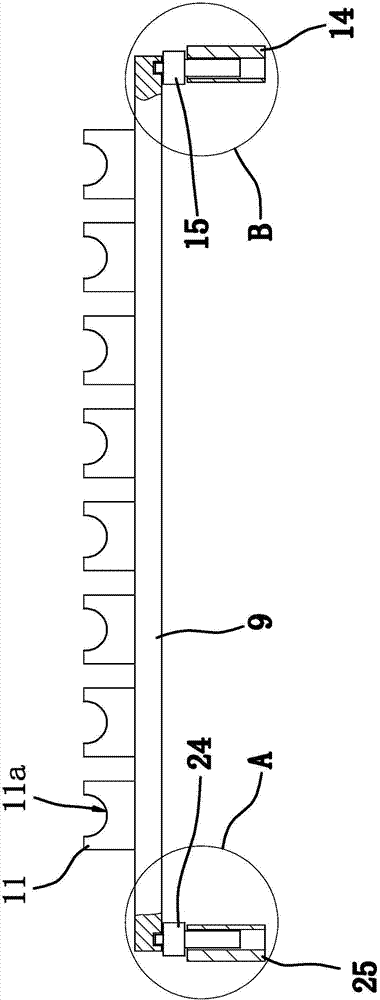

[0071] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

[0072] like Figure 10 Shown, the dyeing method of this imitation cashmere yarn comprises the following steps:

[0073] a. Blank inspection: inspect the imitation cashmere yarn blanks purchased from outside, and remove the unqualified imitation cashmere yarn blanks;

[0074] B, threading; The cashmere-like yarn blank that has passed the inspection is placed on the dyeing rod according to the number of skeins; in the present embodiment, ten skeins of the cashmere-like yarn blank are put on each dyeing rod;

[0075] c. Preparation of dye liquor: put the solid dye into the mixing bucket of the stirring device, add a certain amount of water, and completely dissolve the dye through the stirring device to form a dye liquor;

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com