Method for regulating and controlling crystal form of lysozyme by using ionic liquid

A technology of ionic liquid and lysozyme, which is applied in the direction of biochemical equipment and methods, enzymes, hydrolytic enzymes, etc., can solve problems such as poor crystal form consistency, crystallization rate needs to be further improved, and solid-liquid separation is not easy to achieve, etc. Achieve the effects of convenient operation, easy process control, and easy solid-liquid separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

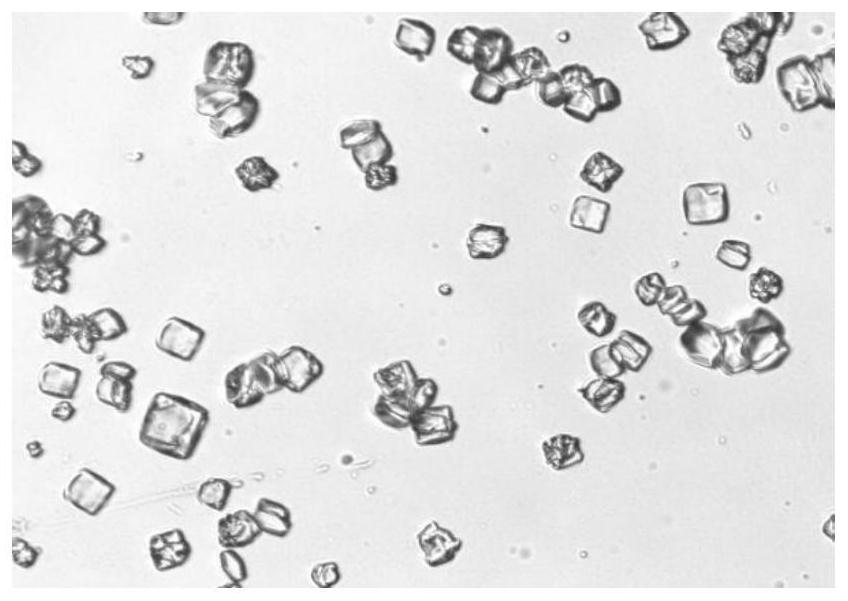

Embodiment 1

[0039] A method utilizing ionic liquid to regulate lysozyme crystal form, comprising the following steps:

[0040] (1) The water-soluble imidazolium-based ionic liquid 1-ethyl-3-methylimidazolium tetrafluoroborate [Emim]BF 4 Join in solution I, make water-soluble imidazolium-based ionic liquid [Emim] BF 4 The mass concentration is 1%, and the solution I has a pH value of 5.0 and contains 0.1M (NH 4 ) 2 SO 4 Potassium dihydrogen phosphate buffer;

[0041] (2) Add excess lysozyme to the liquid obtained in step (1), and stir the lysozyme at 20° C. with a stirring rate of 200 rpm for 20 min;

[0042] (3) the suspension obtained in step (2) is filtered through a sand core funnel under reduced pressure rapidly to obtain a saturated solution of lysozyme;

[0043] (4) Cool the lysozyme-saturated solution obtained in step (3) to 0°C at a cooling rate of 5°C / h, maintain stirring at 150rpm during this period, and maintain crystal growth for 1h;

[0044](5) The crystal suspension ob...

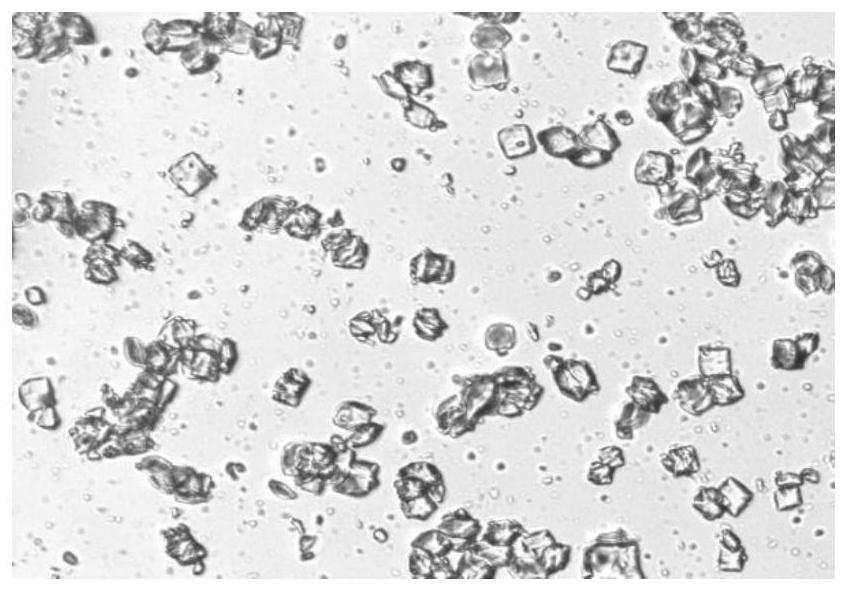

Embodiment 2

[0046] A method utilizing ionic liquid to regulate lysozyme crystal form, comprising the following steps:

[0047] (1) Water-soluble imidazolium-based ionic liquid 1-ethyl-3-methylimidazolium bromide [Emim]Br is added in solution I, the mass concentration that makes water-soluble imidazolium-based ionic liquid [Emim]Br is 3%, The solution I is 6.0 with a pH value of 5% containing 0.1M (NH 4 ) 2 SO 4 dipotassium hydrogen phosphate buffer;

[0048] (2) Add excess lysozyme to the liquid obtained in step (1), and stir the lysozyme at 30° C. at a stirring rate of 250 rpm for 30 min;

[0049] (3) the suspension obtained in step (2) is filtered through a sand core funnel under reduced pressure rapidly to obtain a saturated solution of lysozyme;

[0050] (4) Cool the lysozyme-saturated solution obtained in step (3) to 5°C at a cooling rate of 10°C / h, maintain stirring at 250rpm during this period, and maintain crystal growth for 3h;

[0051] (5) The crystal suspension obtained in...

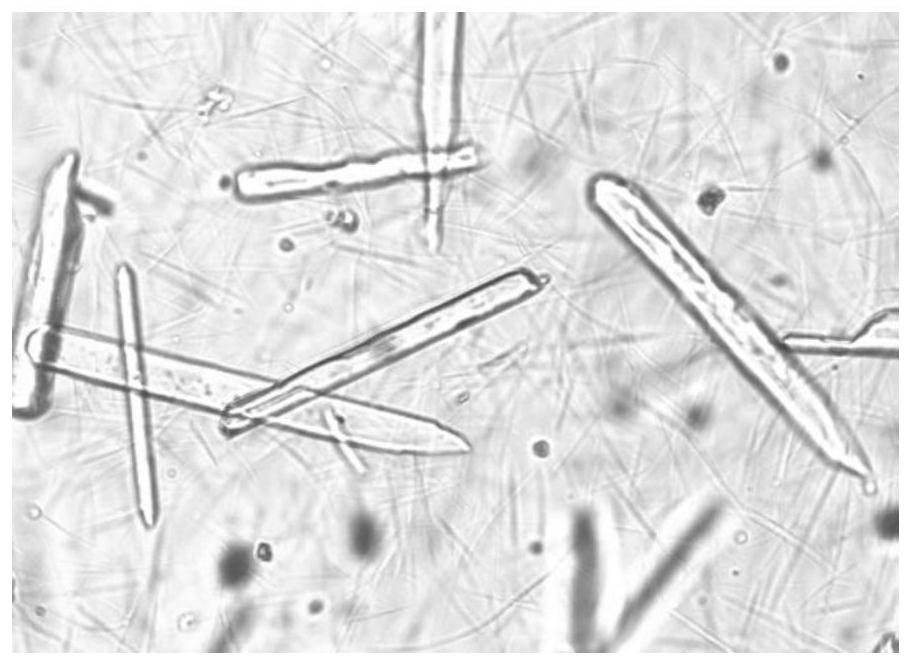

Embodiment 3

[0053] A method utilizing ionic liquid to regulate lysozyme crystal form, comprising the following steps:

[0054] (1) Water-soluble imidazolium-based ionic liquid 1,3-dimethylimidazolium iodonium salt [dmim] I is added in solution I, the mass concentration that makes water-soluble imidazolium-based ionic liquid [dmim] I is 1%, described Solution I is pH 5.0, containing 0.1M (NH 4 ) 2 SO 4 Potassium dihydrogen phosphate buffer;

[0055] (2) Add excess lysozyme to the liquid obtained in step (1), and stir the lysozyme at 20° C. with a stirring rate of 200 rpm for 20 min;

[0056] (3) the suspension obtained in step (2) is filtered through a sand core funnel under reduced pressure rapidly to obtain a saturated solution of lysozyme;

[0057] (4) Cool the lysozyme-saturated solution obtained in step (3) to 0°C at a cooling rate of 5°C / h, maintain stirring at 150rpm during this period, and maintain crystal growth for 1h;

[0058] (5) The crystal suspension obtained in step (4)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com