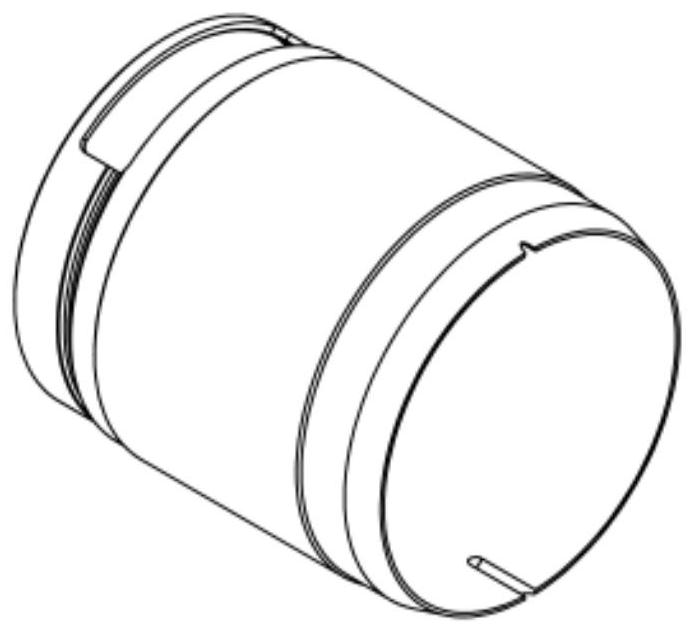

Composite coating for wear-proof casing of petroleum drilling tool and preparation method of composite coating

A composite coating and wear-resistant sleeve technology, applied in the direction of coating, metal material coating process, etc., to achieve the effect of low dilution rate, high impact toughness, and excellent wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

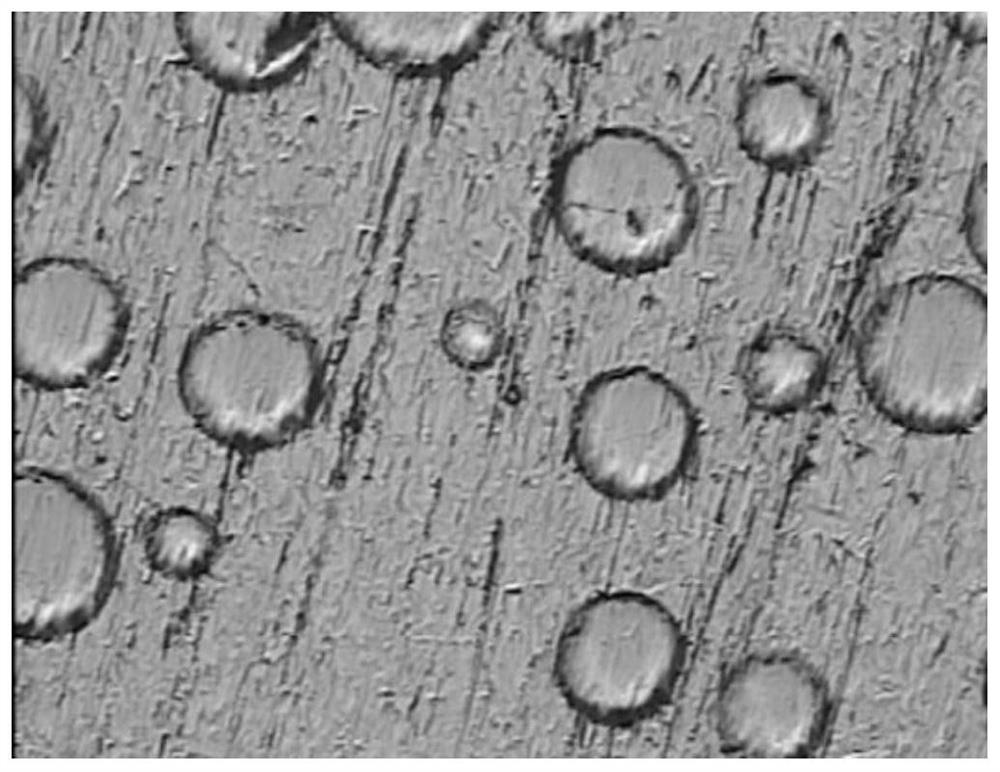

[0050] The preparation method of the above-mentioned composite coating for the oil drilling tool wear-resistant sleeve comprises the following steps:

[0051] (1) Grind the base material with sandpaper, wash off the surface oil with acetone, preheat the base material after drying, and the preheating temperature is 230-280°C;

[0052] (2) Use an analytical balance to weigh a certain amount of graphene according to the mass percentage, add absolute ethanol, and disperse it in a CF-600Y ultrasonic processor for 3 hours, with a power of 2 kilowatts, and add nickel-based alloy powder in proportion to the graphene dispersion and tungsten carbide powder, and finally put the mixed powder into a ball mill for 10 hours to make the powder mix evenly; then place it in a vacuum drying oven for drying at 150°C for 3-5 hours before use;

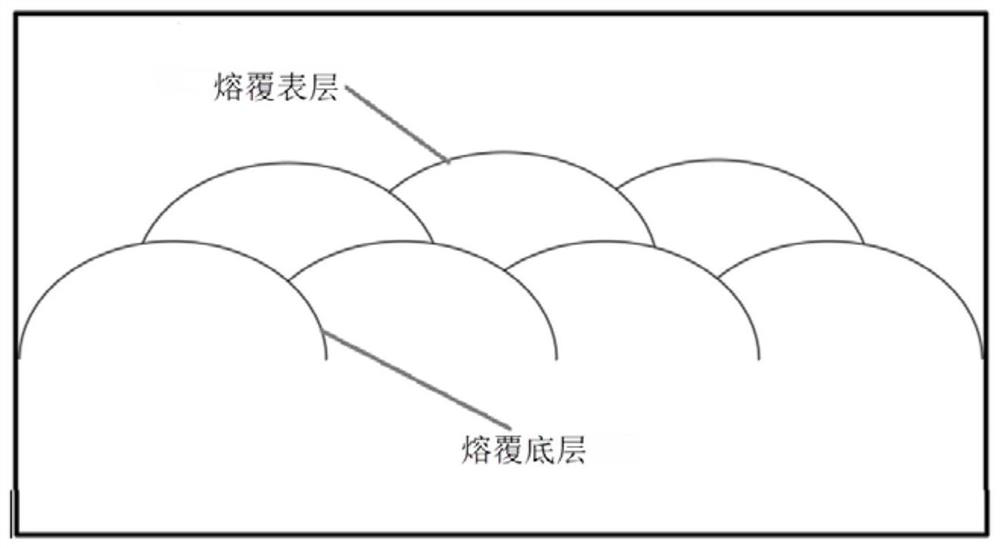

[0053] According to the process of step (2), the raw materials for the cladding bottom layer and the raw materials for the cladding surface layer are respe...

Embodiment 1

[0060] (1) Coating formula composition and ratio

[0061] a. Cladding bottom layer: in terms of mass percentage, nickel-based alloy powder 66%, tungsten carbide powder 31%, graphene powder 3%;

[0062] b. Cladding surface layer: in terms of mass percentage, 46% of nickel-based alloy powder, 51% of tungsten carbide powder, and 3% of graphene powder. After mixing evenly, place in a vacuum drying oven, dry at 150°C for 3 hours, and set aside.

[0063] (2) Base material pretreatment

[0064] Grind the surface of the base material of the wear-resistant sleeve with sandpaper, remove the surface oil with acetone, preheat the base material after drying, and the preheating temperature is 250°C.

[0065] (3) Preparation of coating by laser cladding

[0066] Put the uniformly mixed and dry compound powder of a formula into the automatic powder feeding device, and under the protection of high-purity argon, use the coaxial powder feeding process to send the powder to the surface of the ...

Embodiment 2

[0073] (1) Coating formula composition and ratio

[0074] a. Cladding bottom layer: according to mass percentage, nickel-based alloy powder 66%, tungsten carbide powder 32%, graphene powder 2%;

[0075] b. Cladding surface layer: in terms of mass percentage, 46% of nickel-based alloy powder, 52% of tungsten carbide powder, and 2% of graphene powder. After mixing evenly, place in a vacuum drying oven, dry at 150°C for 3 hours, and set aside.

[0076] (2) Base material pretreatment

[0077] Grind the surface of the base material of the wear-resistant sleeve with sandpaper, remove the surface oil with acetone, preheat the base material after drying, and the preheating temperature is 240°C.

[0078] (3) Preparation of coating by laser cladding

[0079] Put the uniformly mixed and dry compound powder of a formula into the automatic powder feeding device, and under the protection of high-purity argon, use the coaxial powder feeding process to send the powder to the surface of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Microhardness | aaaaa | aaaaa |

| Microhardness | aaaaa | aaaaa |

| Microhardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com