Humidity-control barrier composite film as well as preparation method and application thereof

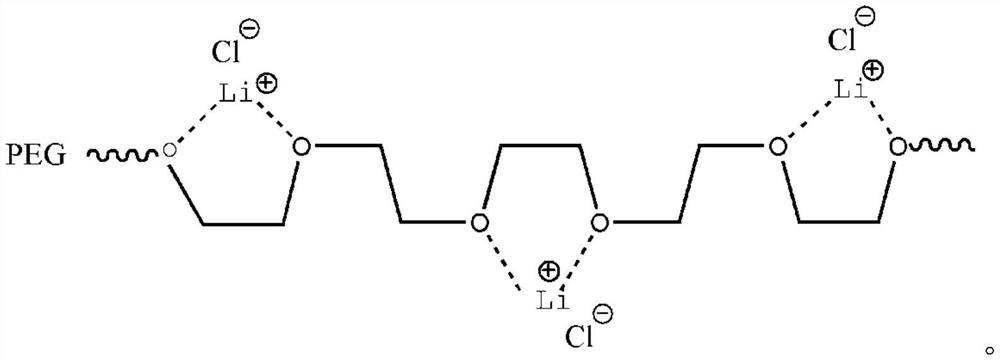

A composite film and porous film technology, applied in the field of moisture control barrier composite film and its preparation, can solve the problems of excessive chlorine content, lack of intelligent moisture control, poor high moisture permeability and other problems in the composite film

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0069] 2kg polypropylene is stretched into a polypropylene porous film on a film unidirectional stretching machine.

[0070] Add 5 g of polyvinyl alcohol A and 0.5 g of polyethylene glycol (molecular weight: 10,000) into 94.15 g of distilled water to fully dissolve. Add 0.1g of nanometer zinc oxide and 0.25g of glutaraldehyde to the obtained solution, stir well until the mixture is uniform, and adjust the pH of the solution to 2 with sulfuric acid to obtain a coating solution. Brush this coating solution evenly on one side of the polypropylene porous film, then place it in an oven and dry it at 70°C for 10 minutes. After contacting the additional layer of polyvinyl alcohol of the composite film with a lithium chloride aqueous solution with a mass concentration of 1% for 1 min, drain the liquid, and dry it at 90°C for 5 min to obtain the intelligent moisture control barrier composite film A1, the thickness of the base layer is 70 micron, the pore diameter is 0.25 micron, the p...

Embodiment 2

[0072] 2kg polypropylene is stretched into a polypropylene porous film on a film unidirectional stretching machine.

[0073] Add 7.5g of polyvinyl alcohol B and 2.0g of polyethylene glycol (molecular weight: 20,000) into 90g of distilled water to fully dissolve. Add 0.25g of nanometer zinc oxide and 0.25g of glutaraldehyde to the obtained solution, stir well until the mixture is uniform, and adjust the pH of the solution to 2 with sulfuric acid to obtain a coating solution. Brush this coating solution evenly on one side of the polypropylene porous film, then place it in an oven and dry it at 70°C for 10 minutes. Then contact the additional layer of polyvinyl alcohol of the composite film with a lithium bromide aqueous solution with a mass concentration of 5% for 1 minute, drain the liquid, and dry it at 70° C. for 10 minutes to obtain an intelligent moisture control barrier composite film A2, the thickness of the base layer is 70 microns, The pore diameter is 0.25 microns, th...

Embodiment 3

[0075] 2kg of polyethylene is stretched into a polyethylene porous film on a film unidirectional stretching machine.

[0076] Add 2.5g of polyvinyl alcohol A and 0.3g of polyethylene glycol (molecular weight: 5000) into 97g of distilled water to fully dissolve. Add 0.1g of nanometer zinc oxide and 0.1g of glutaraldehyde to the obtained solution, stir well until the mixture is uniform, and adjust the pH of the solution to 2 with sulfuric acid to obtain a coating solution. Brush this coating solution evenly on one side of the polyethylene porous film, then place it in an oven and dry it at 70°C for 10 minutes. Then contact the additional layer of polyvinyl alcohol of the composite film with the lithium sulfate aqueous solution with a mass concentration of 5% for 5 minutes, drain the liquid, and dry it at 60°C for 20 minutes to obtain the intelligent moisture control barrier composite film A3, the thickness of the base layer is 70 microns , the pore diameter is 0.25 microns, the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com