Intelligent humidity-control barrier composite film and preparation method and application thereof

A composite film, intelligent moisture control technology, used in transportation and packaging, containers to prevent rot, polyether coatings, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

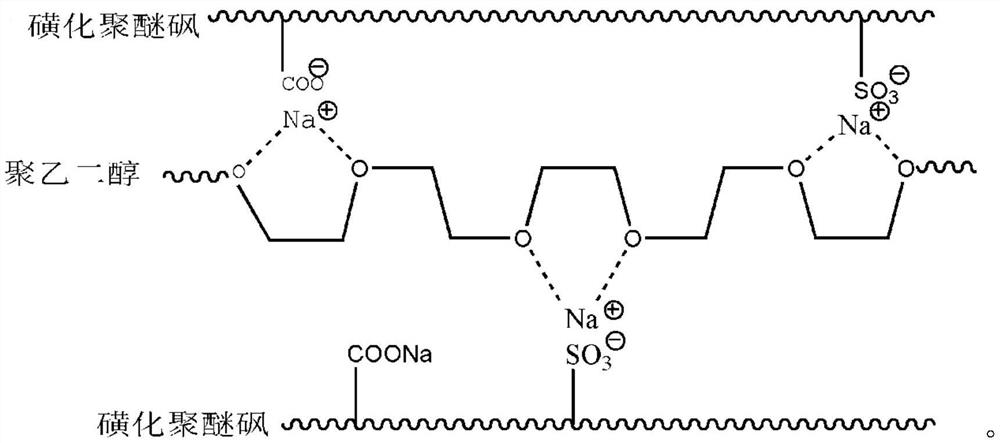

Method used

Image

Examples

Embodiment 1

[0051] 2kg polypropylene is stretched into a polypropylene porous film on a film unidirectional stretching machine.

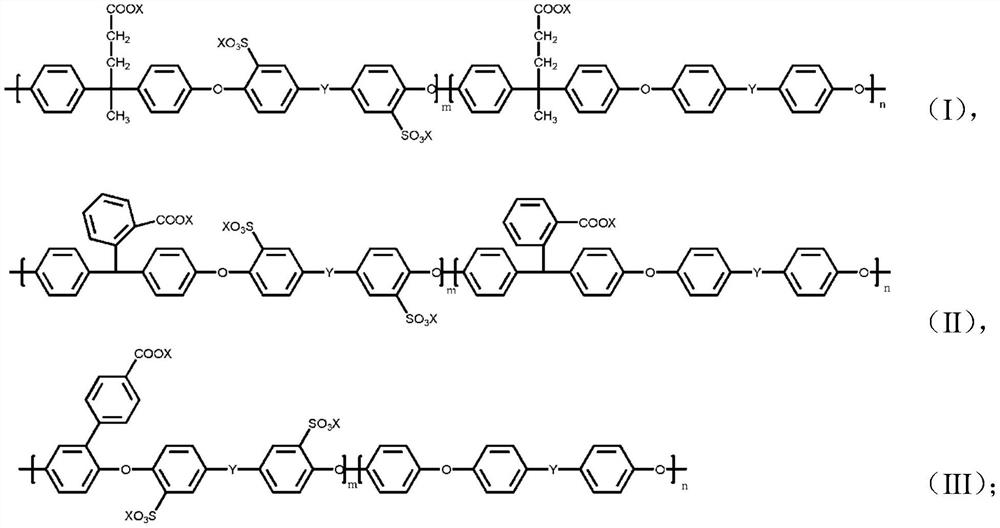

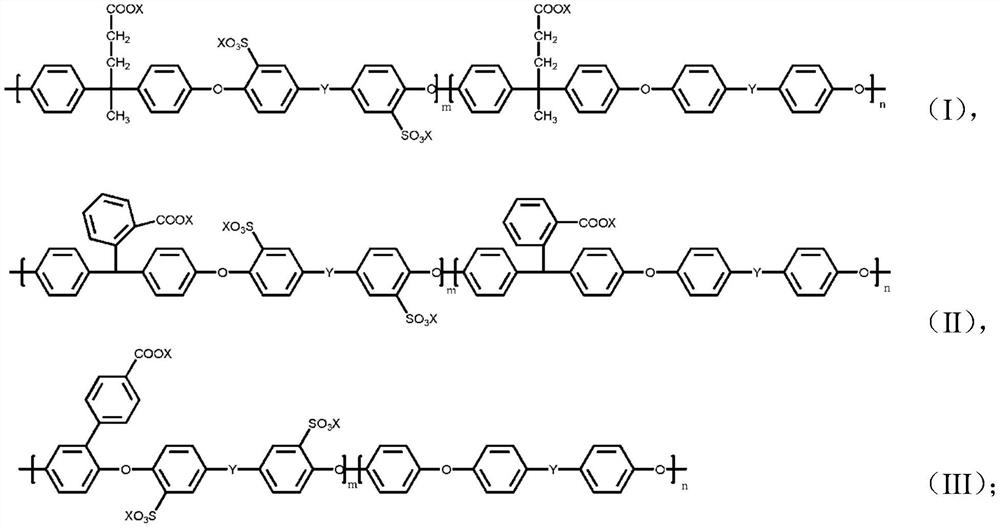

[0052] Add 5g of polyethersulfone (with an ion exchange capacity of 2.0mmol / g) and 0.5g of polyethylene glycol (with a molecular weight of 10,000) containing carboxylate and sulfonate sodium salt groups with a formula I structure to 94.3g N , N-dimethylformamide, fully dissolved. Add 0.2g of nanometer zinc oxide into the obtained solution, stir well until the mixture is uniform, and obtain a coating solution. Brush this coating solution evenly on one side of the polypropylene porous film, then place it in an oven, and dry it at 90°C for 5 minutes to obtain the intelligent moisture-control barrier composite film A1. The thickness of the base layer is 70 microns, and the pore diameter is 0.25 micron, porosity is 50%, and the pores whose pore diameter is in the range of plus or minus one order of magnitude of the average pore diameter account for more than 85% of...

Embodiment 2

[0054] 2kg polypropylene is stretched into a polypropylene porous film on a film unidirectional stretching machine.

[0055] Add 7.5g polyethersulfone (its ion exchange capacity is 1.7mmol / g) and 0.2g polyethylene glycol (molecular weight: 100000) containing carboxylate and sulfonate sodium salt groups with II formula structure to 91.8g N, N- dimethylacetamide, fully dissolved. Add 0.5g of nanometer zinc oxide into the obtained solution, stir well until the mixture is uniform, and obtain a coating solution. Brush this coating solution evenly on one side of the polypropylene porous film, then place it in an oven, and dry it at 50°C for 20 minutes to obtain an intelligent moisture-controlling barrier composite film A2. The thickness of the base layer is 70 microns, and the pore diameter is 0.25 microns, the porosity is 50%, and the pores whose pore diameter is within the range of plus or minus one order of magnitude of the average pore diameter account for more than 85% of all ...

Embodiment 3

[0057] 2kg of polyethylene is stretched into a polyethylene porous film on a film unidirectional stretching machine.

[0058] Add 2.5g polyethersulfone (its ion exchange capacity is 1.8mmol / g) and 0.1g polyethylene glycol (molecular weight is 50000) containing carboxylate and sulfonate sodium salt groups with III formula structure to 97.3g N, N-dimethylacetamide, fully dissolved. Add 0.1 g of nanometer zinc oxide into the obtained solution, stir well until the mixture is uniform, and obtain a coating solution. Brush this coating solution evenly on one side of the polypropylene porous film, then place it in an oven, and dry it at 70°C for 10 minutes to obtain the intelligent moisture-controlling barrier composite film A2. The thickness of the base layer is 70 microns, and the pore diameter is 0.25 micron, the porosity is 50%, and the pores whose pore diameter is within an order of magnitude of the average pore diameter account for more than 85% of all pores; the thickness of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com