Metal indium-doped cesium lead bromide perovskite quantum dot photocatalyst and preparation method thereof, and application of metal indium-doped cesium lead bromide perovskite quantum dot photocatalyst in reduction of carbon dioxide

A photocatalyst and quantum dot technology, applied in the directions of carbon monoxide, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problems of unsatisfactory photocatalytic reduction selectivity, weak carbon dioxide adsorption capacity, humidity sensitivity, etc., to improve the activity and the effects of selectivity, reduced sensitivity, and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

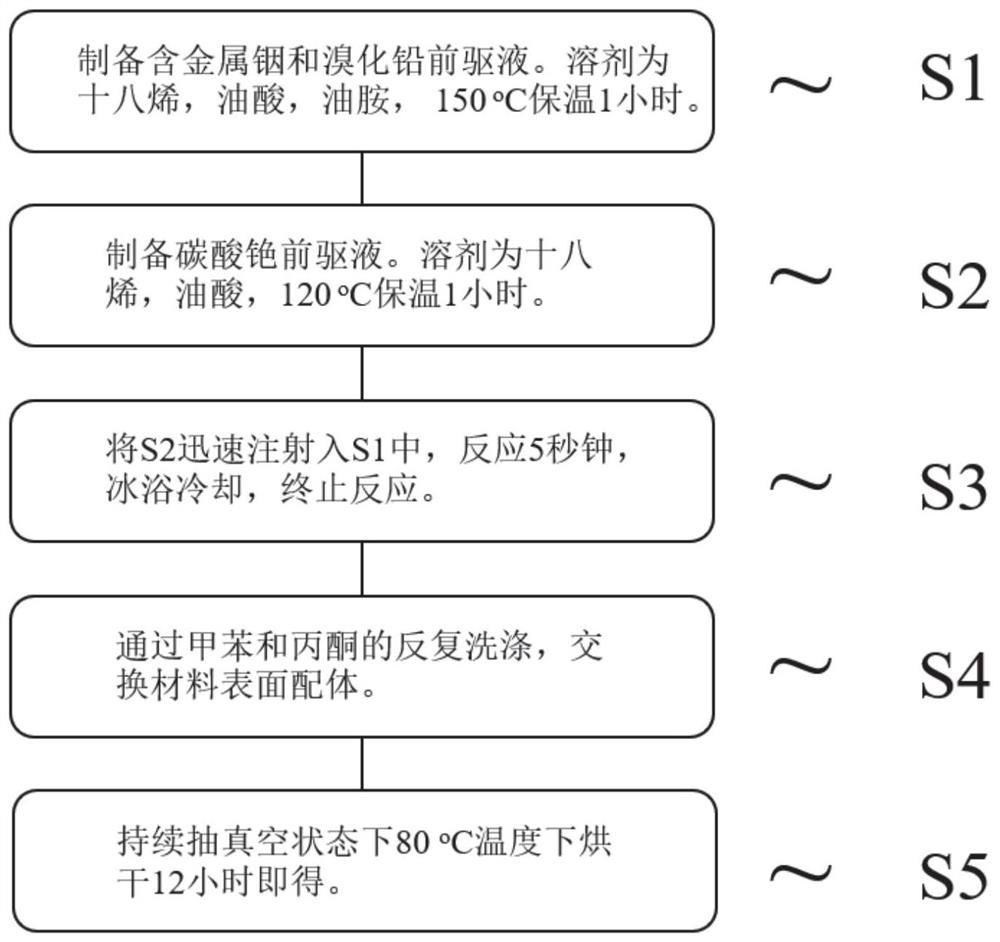

[0038] Refer to attached figure 1 A kind of preparation method of perovskite quantum dot photocatalyst disclosed by the invention comprises the following steps:

[0039] S1. Preparation of a precursor solution containing metal indium and lead bromide. The solvent is octadecene, oleic acid, and oleylamine, and the temperature is kept at 150° C. for 1 hour.

[0040] S2. Prepare cesium carbonate precursor solution. The solvent is octadecene and oleic acid, and the temperature is kept at 120° C. for 1 hour.

[0041] S3. Rapidly inject S2 into S1, react for 5 seconds, and cool in an ice bath to terminate the reaction.

[0042] S4. Exchange catalyst surface ligands by repeated washing with toluene and acetone.

[0043] S5. It can be obtained by drying at 80°C for 12 hours under continuous vacuuming.

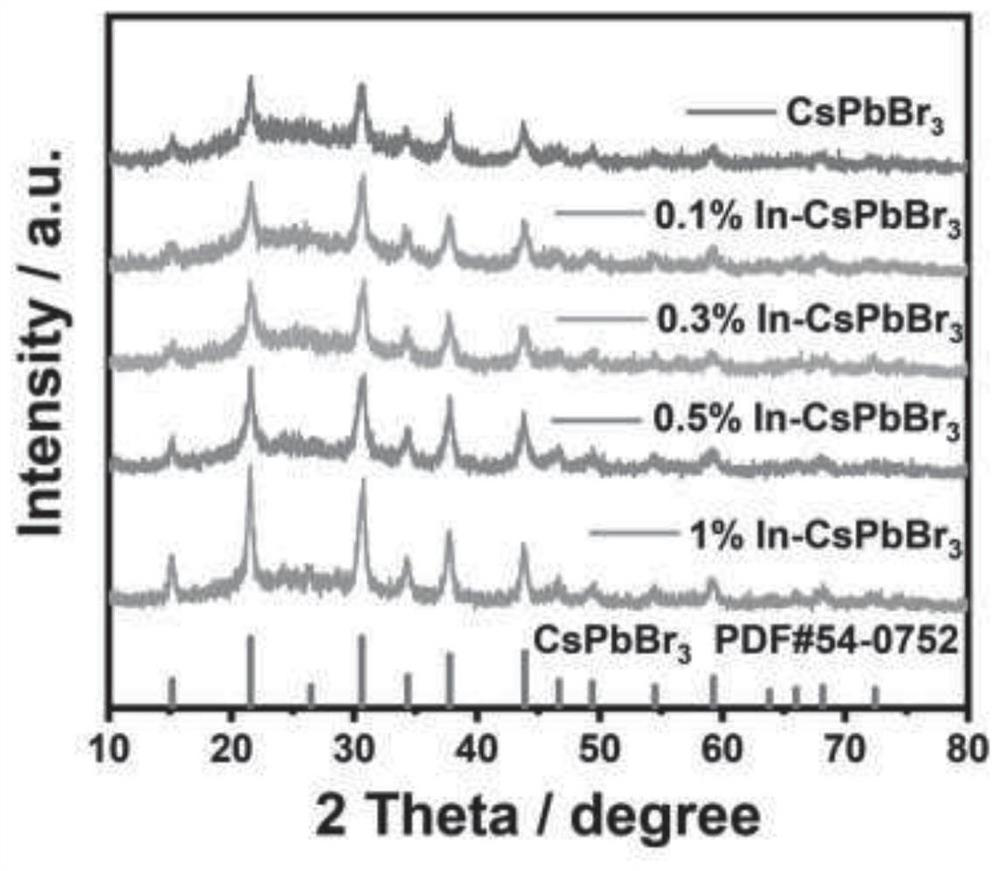

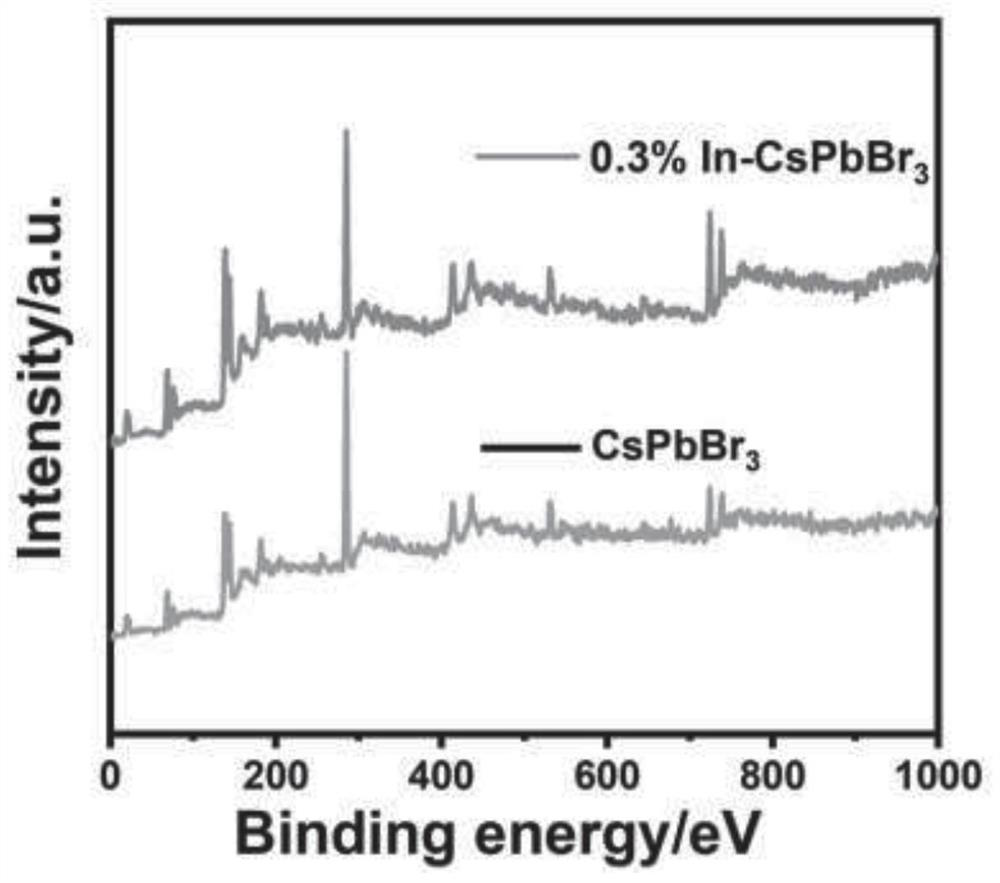

[0044] Metal indium doped CsPbBr prepared by this experimental example 3 Characterization of perovskite quantum dot photocatalysts shows that metal indium doped CsPbBr 3 Perovsk...

Embodiment 1

[0057] A pure phase of CsPbBr 3 The preparation method of perovskite quantum dot photocatalyst comprises the following steps:

[0058] S1: Dissolve 207mg lead bromide in 15ml octadecene, heat to 120°C under the protection of argon, keep the temperature constant for 1 hour, add 1.5ml oleylamine and 1.5ml oleic acid, heat up to 150°C until The solid dissolves completely, producing a lead bromide precursor.

[0059] S2: Dissolve 27mg of cesium carbonate in 1ml of octadecene, add 0.2ml of oleic acid, heat to 120°C under the protection of argon, and keep the temperature constant for 1 hour to completely dissolve the cesium carbonate to generate a cesium carbonate precursor.

[0060] S3: Rapidly inject the cesium carbonate precursor solution into it, react for 5 seconds, and quickly cool down to room temperature through an ice bath to terminate the reaction.

[0061] S4: Centrifuge at 10,000 rpm for 5 minutes in a centrifuge to obtain the lower solid. Add 10ml of toluene to the s...

Embodiment 2

[0065] A metal indium doped CsPbBr 3 The preparation method of perovskite quantum dot photocatalyst comprises the following steps:

[0066] S1: Dissolve 207mg lead bromide and 0.6mg indium bromide in 15ml octadecene, heat to 120°C under the protection of argon, keep the temperature constant for 1 hour, add 1.5ml oleylamine and 1.5ml oleic acid, Raise the temperature to 150°C until the solid is completely dissolved to generate a precursor solution containing metal indium and lead bromide.

[0067] S2: Dissolve 27mg of cesium carbonate in 1ml of octadecene, add 0.2ml of oleic acid, heat to 120°C under the protection of argon, and keep the temperature constant for 1 hour to completely dissolve the cesium carbonate to generate a cesium carbonate precursor.

[0068] S3: Rapidly inject the cesium carbonate precursor solution into it, react for 5 seconds, and quickly cool down to room temperature through an ice bath to terminate the reaction.

[0069] S4: Centrifuge at 10,000 rpm f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com