On-site detection method for content of heavy metal elements in aquatic products

A technology for on-site detection and element content, applied in the field of heavy metal detection, can solve problems such as inability to apply on-site detection and complex electrode processing, and achieve the effects of portable equipment and reagents, simple electrode processing methods, and stable detection systems.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] An on-site detection method for the content of heavy metal elements in aquatic products uses equipment including sample pretreatment equipment, sample analysis equipment, several reagents and test analysis consumables.

[0048] Sample pretreatment equipment includes: small grinder (grinding cup size 200mL ~ 1000mL), small centrifuge, electronic balance, adjustable pipette. The sample analysis equipment is: portable electrochemical workstation (three-electrode system: glassy carbon electrode, silver / silver chloride electrode, platinum electrode). Commercially available; crayfish matrix reference material (standard sample of freeze-dried powder of aquatic products, cadmium content: 0.003-0.960 mg / kg) prepared by homogenizing and freeze-drying, and determined by inductively coupled plasma mass spectrometry (ICP-MS). Mercury chloride, sodium tetraborate decahydrate, sodium diacetate, hydrochloric acid, Aladdin Reagent Company; the reagents used were of superior grade, and t...

Embodiment 2

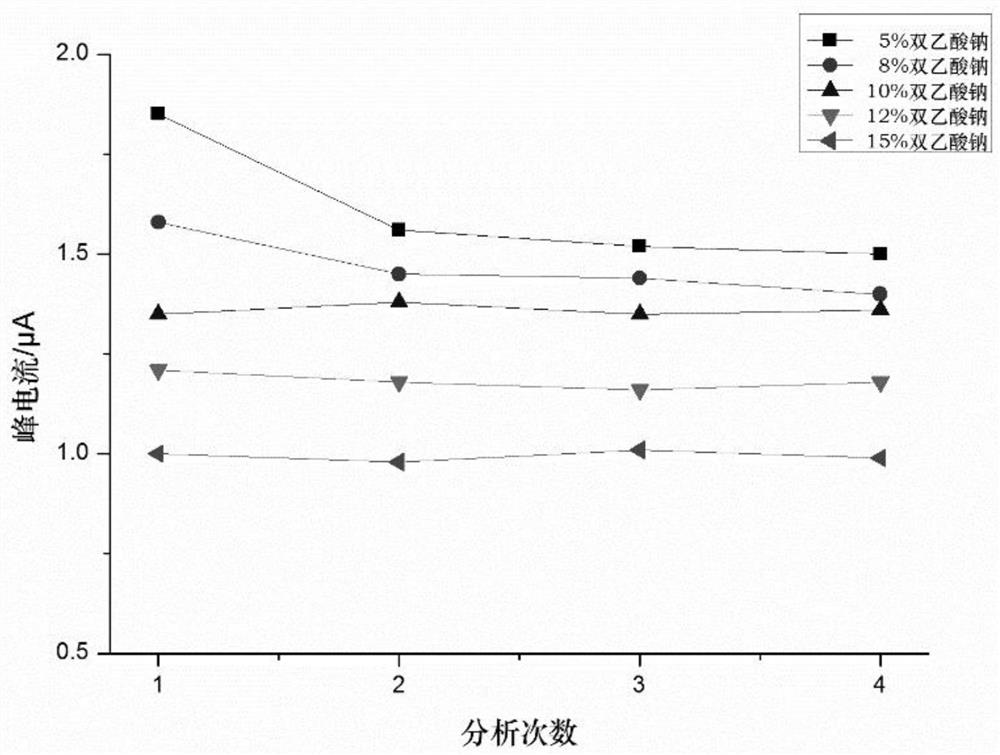

[0062] The difference between this example and Example 1 is that 10ml of 0.2mol / L hydrochloric acid is used for shaking and dissolving, the concentration of the sodium diacetate solution is 15%, the enrichment voltage is -1350mV, the enrichment time is 100s, and the mixture is stirred. The time is 6s, the holding voltage is -950mV, the holding time is 13s, the scanning start voltage is -950V, the scanning end voltage is -450mV, the scanning rate is 450mV, the cleaning voltage is 38mV, and the cleaning time is 4s.

Embodiment 3

[0064] The difference between this example and Example 1 is that 10 ml of 0.6 mol / L hydrochloric acid is used for shaking and dissolving, the concentration of the sodium diacetate solution is 5%, the enrichment voltage is -1250mV, the enrichment time is 120s, and stirring The time is 4s, the holding voltage is -850mV, and the holding time is 11s; the scanning start voltage is -850mV, the scanning end voltage is -350mV, the scanning rate is 550mV, the cleaning voltage is 42mV, and the cleaning time is 6s.

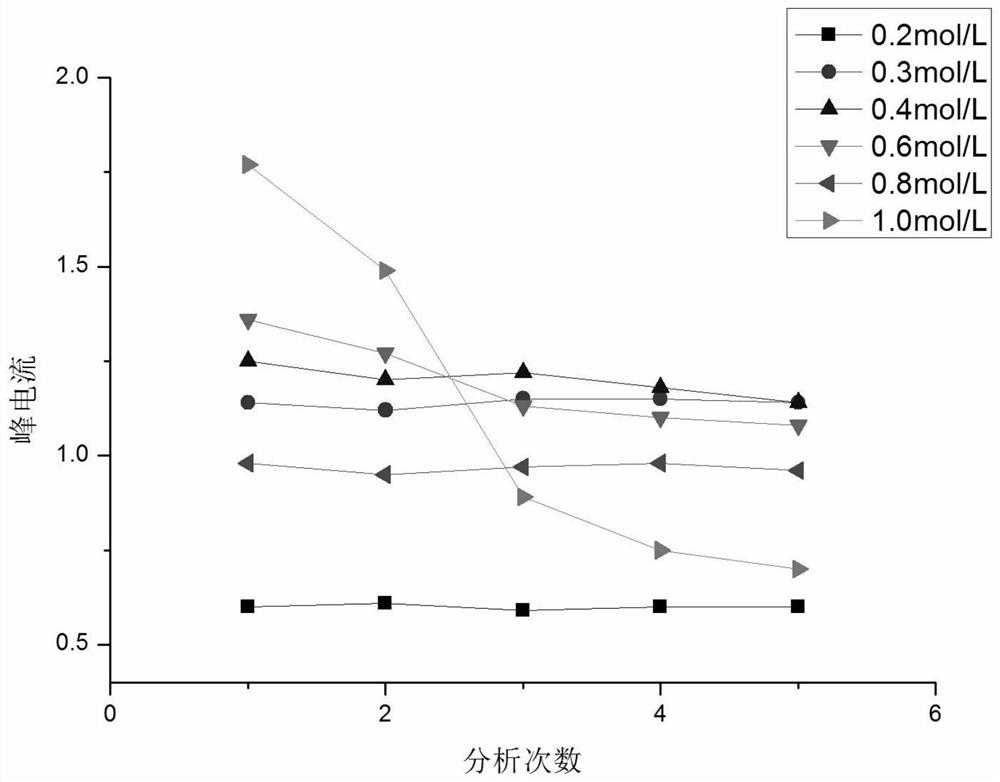

[0065] The traditional wet digestion method needs to use concentrated acid, and the pH needs to be adjusted after the digestion is completed to detect. In order to meet the needs of fast and efficient on-site detection, the stability of direct detection without adjusting the pH of the extract is studied. Prepare (0.2-1.0) mol / L hydrochloric acid solution, extract the crayfish matrix reference material, and analyze it by anodic stripping voltammetry. Such as figure 1 As show...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com