Reconstructed titanium-containing blast furnace slag with soil remediation and plant nutrient functions and application of reconstructed titanium-containing blast furnace slag

A technology of soil remediation and blast furnace slag, applied in the direction of application, inorganic fertilizer, fertilizer mixture, etc., can solve the problems of increased volume of perovskite phase and single product function, and achieve the effect of improving the ability and photocatalytic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0063] The present invention will be further described below in conjunction with specific embodiments.

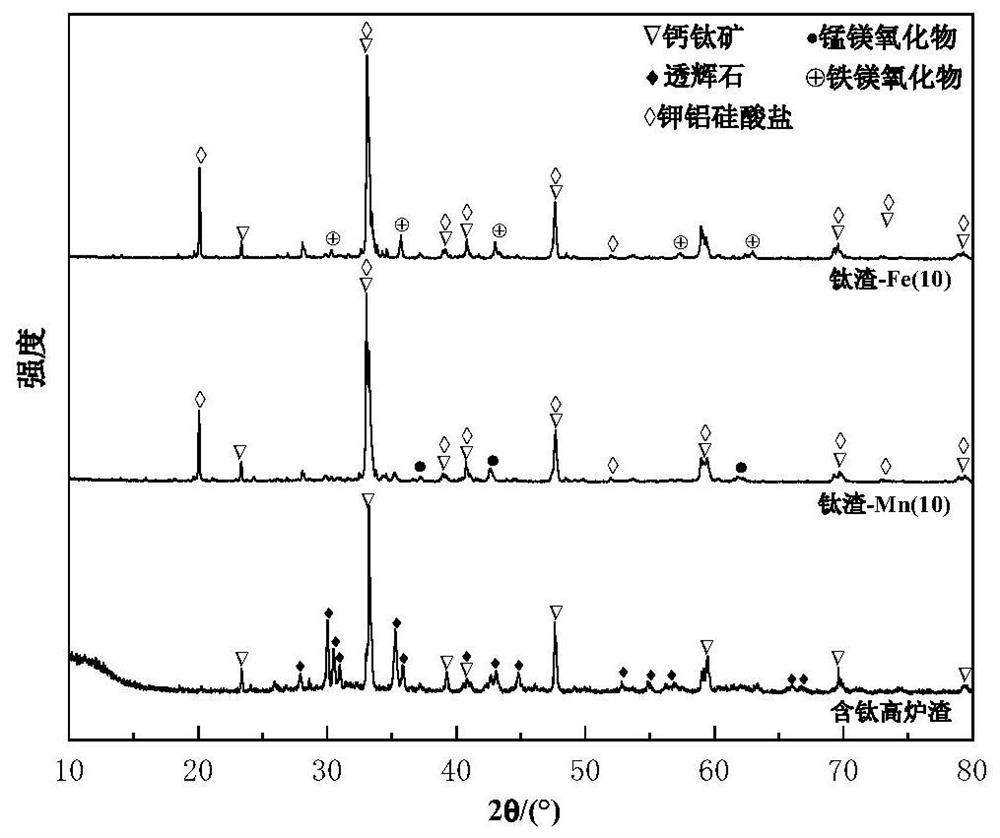

[0064] Dry the titanium-containing blast furnace slag, put it in a grinding tank, and grind it for 60 seconds, then take the titanium-containing blast furnace slag powder, transition metal oxide, and KOH powder, mix and grind them evenly, place them in a crucible, and heat them in a box furnace to 1400 ~1500°C heat preservation for 2 hours, cooling to room temperature with the furnace, then crushing, and then placing it in a grinding tank for grinding for 60s (according to the actual fertilization needs, choose a suitable grinding time). The functional reconstruction of titanium-containing blast furnace slag, the raw material formula of each embodiment is shown in Table 1.

[0065] It is worth noting that in the specific embodiment, KOH powder is selected as one of the raw materials, and other alkaline potassium salt powders can also obtain the reconstructed titanium-contai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com