Zinc-titanium composite surface osteogenesis promoting implant and preparation method thereof

A composite surface and implant technology, applied in prosthesis, coating, medical science, etc., can solve the problem of increasing the surface roughness or osteocompatibility of implants, no improvement in bone loss in osteoporosis, and difficult processes. problems such as chemicalization, to achieve the effect of less exposed foreign body sensation, promote differentiation and value-added, and improve stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] In an embodiment of the present invention, a zinc-titanium composite surface promotes bone implant and its preparation method comprises the following steps:

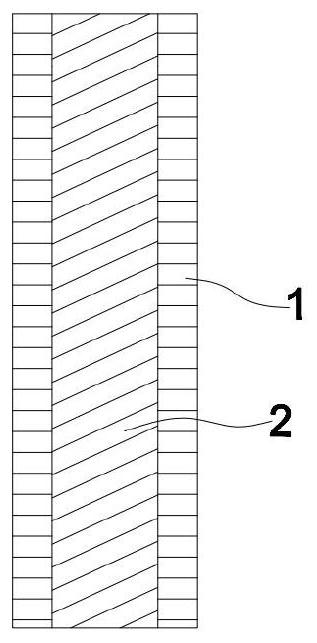

[0031] The surface of pure titanium or titanium alloy rods with a diameter of 9-20mm is polished, sandblasted and acid-etched sequentially to obtain pretreated pure titanium or titanium alloy rods; the zinc alloy rods with a diameter of 11-40mm are perforated, And polish and polish the inner wall after perforation to form a zinc alloy pipe with an outer diameter of 11-40mm and a wall thickness of 1-10mm; after preheating the zinc alloy pipe with an outer diameter of 11-40mm and a wall thickness of 1-10mm, After the pipe is heated, the diameter becomes larger and inserted into the pretreated pure titanium or titanium alloy rod. After the temperature drops to room temperature, the zinc alloy pipe shrinks when it is cold, and forms a tight fixation with the pure titanium or titanium alloy rod to form zinc-titanium Ro...

Embodiment 1

[0034] The surface of a pure titanium rod with a diameter of 9 mm is sequentially subjected to grinding, sandblasting, and acid etching to obtain a pretreated pure titanium rod. A zinc alloy rod with a diameter of 11 mm is perforated, and the inner wall after the perforation is polished to form a zinc alloy pipe with an outer diameter of 11 mm and a wall thickness of 1 mm. After preheating the zinc alloy pipe with an outer diameter of 11mm and a wall thickness of 1mm, put it into the pretreated pure titanium rod while the diameter of the zinc alloy pipe becomes larger after being heated. After the temperature drops to room temperature, the zinc alloy pipe shrinks when it is cold. , and form a tight fixation with pure titanium rods to form zinc-titanium rods. The assembled zinc-titanium rods undergo 2 passes of hot swaging and 2 passes of cold swaging to form composite zinc-titanium rods with a diameter of 4mm. The composite zinc-titanium bar is mechanically turned into an emb...

Embodiment 2

[0036] The surface of a titanium alloy rod with a diameter of 20 mm is sequentially subjected to grinding, sandblasting, and acid etching to obtain a pretreated titanium alloy rod. A zinc alloy rod with a diameter of 40mm is perforated, and the inner wall after the perforation is polished to form a zinc alloy pipe with an outer diameter of 40mm and a wall thickness of 10mm. After preheating the zinc alloy pipe with an outer diameter of 40mm and a wall thickness of 10mm, put it into the pretreated titanium alloy rod while the diameter of the zinc alloy pipe becomes larger after being heated. After the temperature drops to room temperature, the zinc alloy pipe shrinks when it is cold. , and form a tight fixation with titanium alloy rods to form zinc-titanium rods. The assembled zinc-titanium rods undergo 4 passes of hot swaging and 8 passes of cold swaging to form composite zinc-titanium rods with a diameter of 10 mm. The composite zinc-titanium bar is mechanically turned into ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com