Solid acid alkylation process for isoparaffin and olefins

An isoparaffin and alkylation technology, applied in chemical instruments and methods, organic chemistry, refined hydrocarbon oil, etc., can solve the problem of high energy consumption for separation, reduce operating costs, improve catalytic activity and selectivity, reduce The effect of total energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

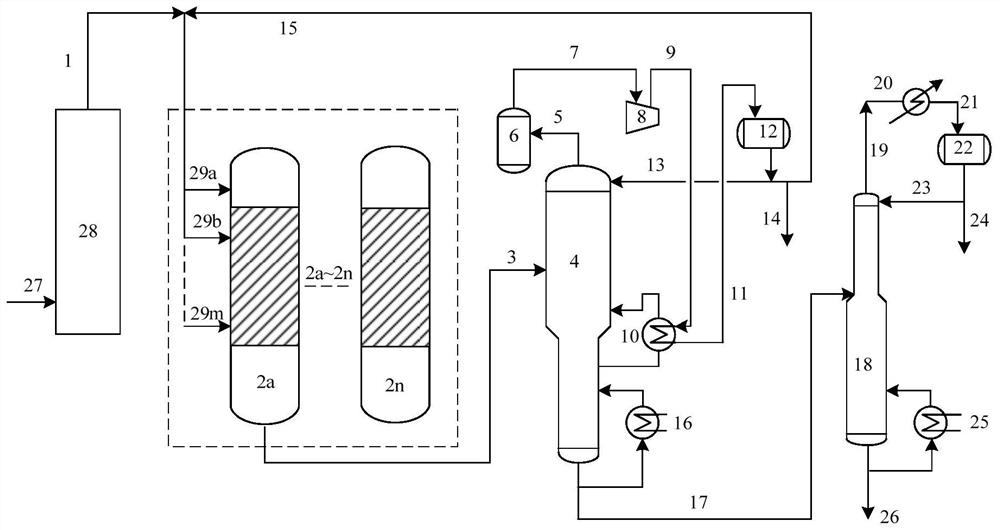

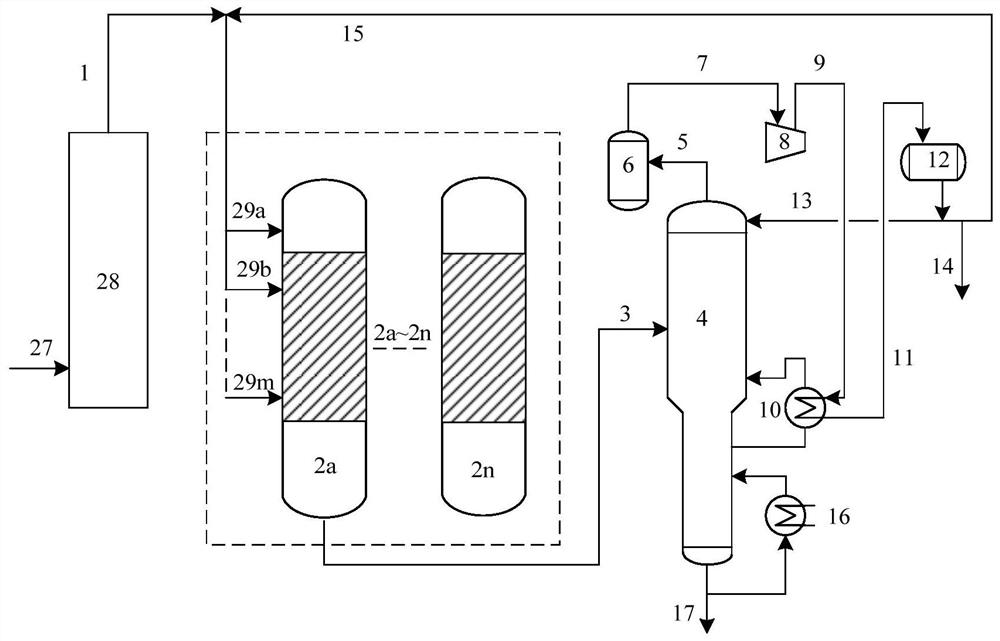

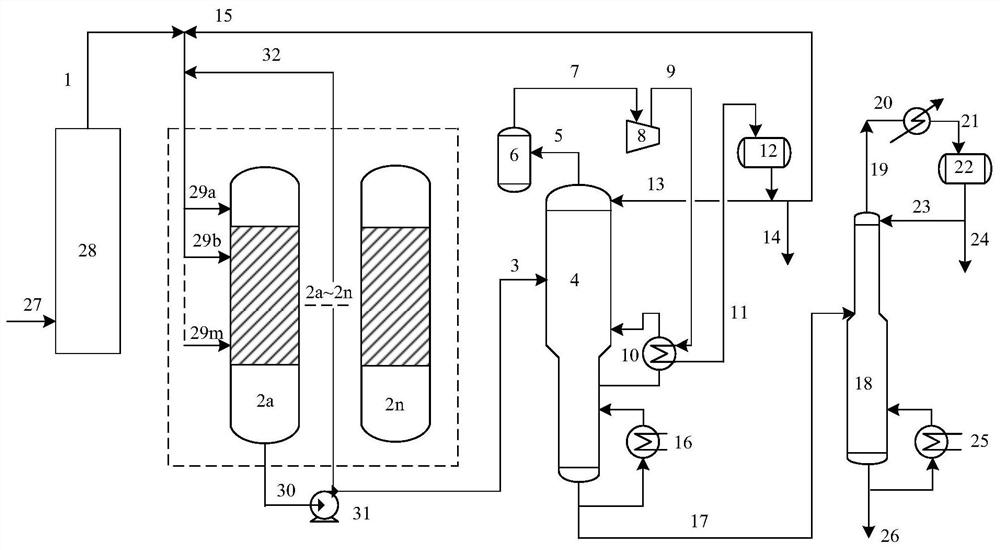

Image

Examples

Embodiment 1

[0083] Example 1 illustrates the alkylation catalyst employed in the present invention.

[0084] Add water and beat the Y-type molecular sieve numbered Ya to a solid content of 200kg / m 3 Molecular sieve slurry, add the aluminum sol numbered Al1 according to the ratio of Ya and Al1 weight dry basis percentage of 60:40, stir for 4h, make it mix evenly, add 3% weight percentage (by molecular sieve and aluminum Sol 600 ℃ after roasting based on the dry basis weight) of nitric acid and turnip powder, and by adding water to ensure that the water-powder ratio is 0.8, kneading evenly and extruding, the obtained wet strips are dried and roasted to obtain a molded solid acid catalyst sample , named 60A1, the properties are shown in Table 1.

[0085] The solid acid catalyst sample 60A1 of embodiment 1 was added under vacuum containing hydrogenation metal Pt(H 2 PtCl 6 ·6H 2 O is the precursor), impregnating solution with a liquid-solid ratio of 2:1, impregnated under normal pressure ...

Embodiment 2

[0088] Example 2 illustrates the alkylation catalyst employed in the present invention.

[0089] Add water and beat the Y-type molecular sieve numbered Ya to a solid content of 200kg / m 3 Molecular sieve slurry, according to the ratio of Ya and Al2 weight dry basis percentage is 80:20, add the aluminum sol that is numbered Al2, stir 4h, make it mix evenly, add 3% weight percentage (by molecular sieve and aluminum Sol 600 ℃ after roasting based on the dry basis weight) of nitric acid and turnip powder, and by adding water to ensure that the water-powder ratio is 0.8, kneading evenly and extruding, the obtained wet strips are dried and roasted to obtain a molded solid acid catalyst sample , named 80A2, the properties are shown in Table 1.

[0090] The solid acid catalyst sample 80A2 of embodiment 2 was added under vacuum containing hydrogenation metal Pt(H 2 PtCl 6 ·6H 2 O is the precursor), impregnating solution with a liquid-solid ratio of 2:1, impregnated under normal pres...

Embodiment 3

[0093] Example 3 illustrates the alkylation catalyst employed in the present invention.

[0094] Add water and beat the Y-type molecular sieve numbered Ya to a solid content of 200kg / m 3 Molecular sieve slurry, according to the ratio of Ya and Al3 weight dry basis percentage is 95:5, add the aluminum sol that is numbered Al3, stir 4h, make it mix evenly, add 3% weight percentage (by molecular sieve and aluminum Sol 600 ℃ after roasting based on the dry basis weight) of nitric acid and turnip powder, and by adding water to ensure that the water-powder ratio is 0.8, kneading evenly and extruding, the obtained wet strips are dried and roasted to obtain a molded solid acid catalyst sample , named 95A3, the properties are shown in Table 1.

[0095] The solid acid catalyst sample 95A3 of embodiment 3 was added under vacuum containing hydrogenation metal Pt(H 2 PtCl 6 ·6H 2 O is the precursor), impregnating solution with a liquid-solid ratio of 2:1, impregnated under normal press...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com