Environment-friendly high-performance geopolymer-based adhesive laminated wood and preparation method thereof

A high-performance, adhesive technology, applied in the direction of adhesives, adhesive additives, polymer adhesive additives, etc., can solve problems such as the bonding performance of wood adhesives that have not been raised, and save time and process costs. Increased utilization, wide-ranging effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

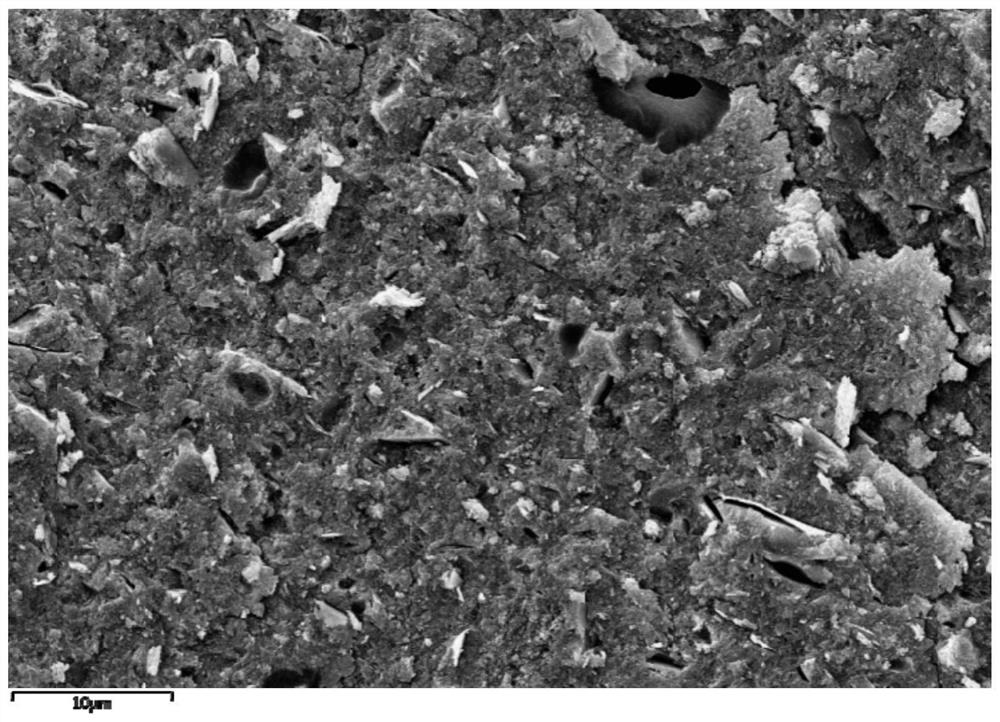

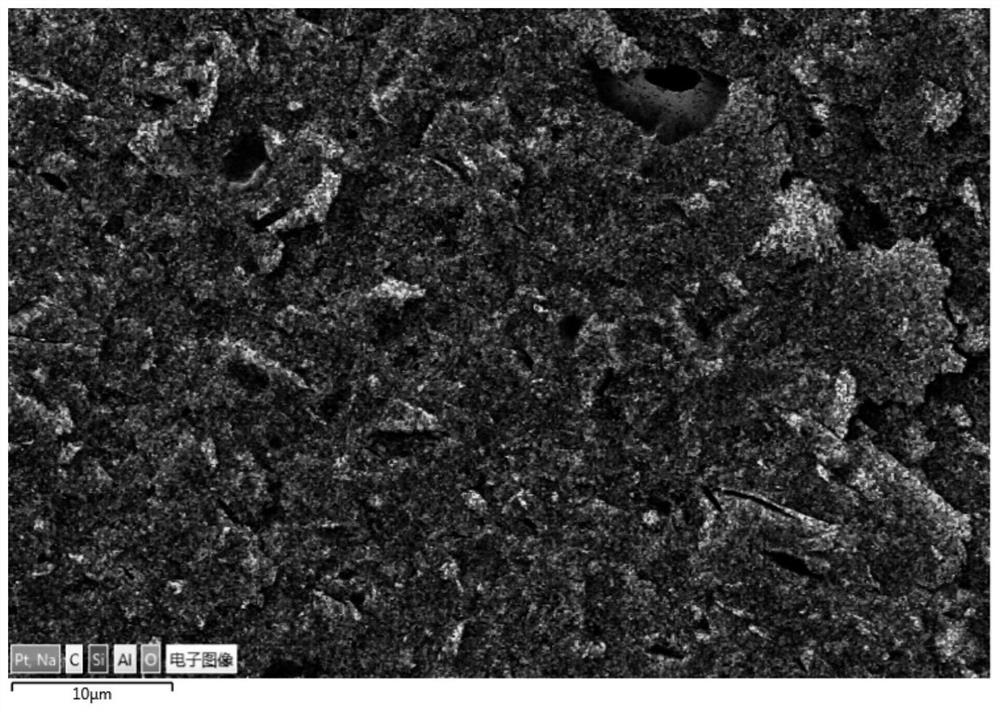

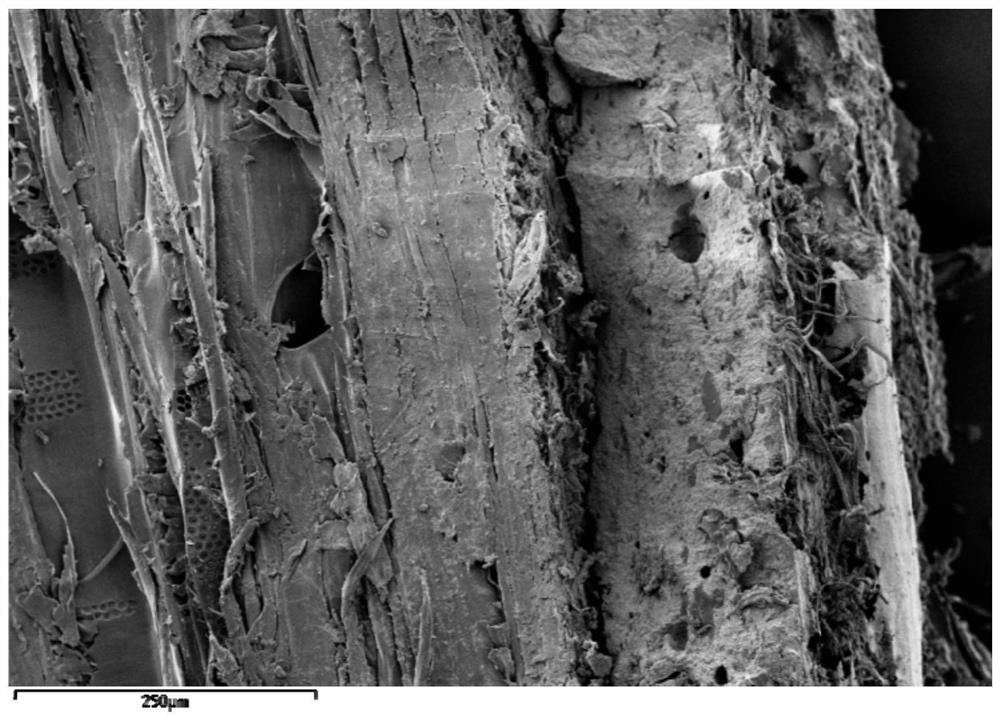

Image

Examples

Embodiment 1

[0045]An environmentally friendly high-performance geopolymer-based wood adhesive-made glulam, the formula of which is calculated by mass and part ratio:

[0046]

[0047] (1) Dissolve 46.7 parts of sodium hydroxide in 100 parts of distilled water and stir magnetically at 500 rpm for 30 minutes. After cooling to room temperature, set the volume to a sodium hydroxide aqueous solution with a concentration of 11.7 mol / L;

[0048] (2) Mix the above 95mL aqueous sodium hydroxide solution with a concentration of 11.7mol / L and 220mL aqueous sodium silicate solution with a modulus of 2.3 at a speed of 1000rpm for 120min with magnetic stirring, and leave it at room temperature for 24h to obtain the required alkali activator .

[0049] (3) Add 2 parts of silane coupling agent KH-550 into 10 parts of styrene-acrylic emulsion, and mix with magnetic stirring at 500 rpm for 30 minutes to form a stable solution.

[0050] (4) Mix the alkali activator obtained in (2) with metakaolin over 1...

Embodiment 2

[0059] An environmentally friendly high-performance geopolymer-based wood adhesive-made glulam, the formula of which is calculated by mass and part ratio:

[0060]

[0061] (1) Dissolve 46.7 parts of sodium hydroxide in 100 parts of distilled water and stir magnetically at 500 rpm for 30 minutes with a rotating speed. After cooling to room temperature, set the volume to a sodium hydroxide aqueous solution with a concentration of 11.7 mol / L;

[0062] (2) Mix the above 95mL aqueous sodium hydroxide solution with a concentration of 11.7mol / L and 220mL aqueous sodium silicate solution with a modulus of 2.3 at a speed of 1000rpm for 120min with magnetic stirring, and leave it at room temperature for 24h to obtain the required alkali activator .

[0063] (3) Add 2 parts of silane coupling agent KH-550 into 10 parts of styrene-acrylic emulsion, and mix with magnetic stirring at 500 rpm for 30 minutes to form a stable solution.

[0064] (4) Mix the alkali activator obtained in (2)...

Embodiment 3

[0073] An environmentally friendly high-performance geopolymer-based wood adhesive-made glulam, the formula of which is calculated by mass and part ratio:

[0074]

[0075] (1) Dissolve 46.7 parts of sodium hydroxide in 100 parts of distilled water and stir magnetically at 500 rpm for 30 minutes. After cooling to room temperature, set the volume to a sodium hydroxide aqueous solution with a concentration of 11.7 mol / L;

[0076] (2) Mix the above 95mL aqueous sodium hydroxide solution with a concentration of 11.7mol / L and 220mL aqueous sodium silicate solution with a modulus of 2.3 at a speed of 1000rpm for 120min with magnetic stirring, and leave it at room temperature for 24h to obtain the required alkali activator .

[0077] (3) Add 2 parts of silane coupling agent KH-550 into 10 parts of styrene-acrylic emulsion, and mix with magnetic stirring at 500 rpm for 30 minutes to form a stable solution.

[0078] (4) Mix the alkali activator obtained in (2) with metakaolin over ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com