Annealing method of 2219 aluminum alloy ingot and 2219 aluminum alloy deformed parts

An aluminum alloy casting ingot and aluminum alloy technology, which is applied in the field of 2219 aluminum alloy deformed parts, can solve the problems of large internal stress, difficulty in breaking, and high content of Cu elements in the ingot, so as to promote the diffusion of alloy elements, improve the deformation processing performance, reduce the Effect of small crack tendency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

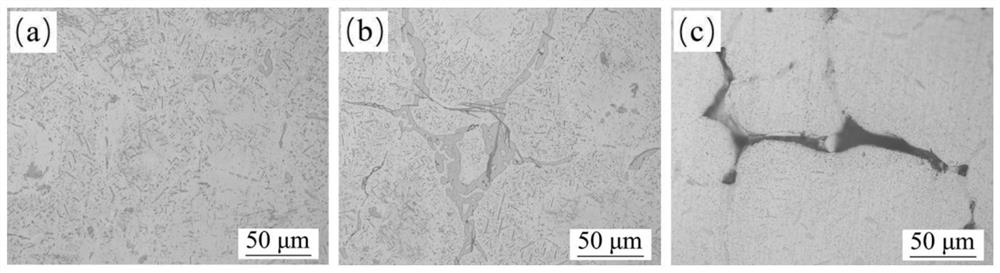

[0054] This embodiment provides a multi-stage homogenization annealing method for a 2219 aluminum alloy ingot with a diameter of 508 mm:

[0055] (1) The first annealing: heat the 2219 aluminum alloy ingot to 200°C at the first heating rate of 50°C / h in a heat treatment furnace, and keep it warm for 4.5h;

[0056] (2) Second annealing: heat the cast ingot after the first annealing treatment to 460°C at the second heating rate of 100°C / h, and keep it warm for 9.5h;

[0057] (3) The third annealing: heat the ingot after the second annealing treatment to 525°C at the third heating rate of 100°C / h, and keep it warm for 24h;

[0058] (4) Cooling: Air-cool the ingot after the third annealing treatment to room temperature.

Embodiment 2

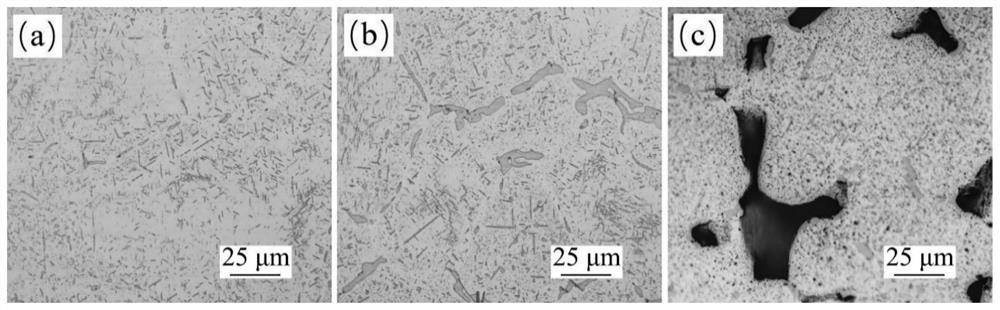

[0067] This embodiment provides a multi-stage homogenization annealing method for a 2219 aluminum alloy ingot with a diameter of 730mm:

[0068] (1) The first annealing: heat the 2219 aluminum alloy ingot to 220°C at the first heating rate of 40°C / h in a heat treatment furnace, and keep it warm for 5.5h;

[0069] (2) Second annealing: heat the cast ingot after the first annealing treatment to 475°C at the second heating rate of 110°C / h, and keep it warm for 11h;

[0070] (3) The third annealing: heat the ingot after the second annealing treatment to 530°C at the third heating rate of 115°C / h, and keep it warm for 27.5h;

[0071] (4) Cooling: Air-cool the ingot after the third annealing treatment to room temperature.

Embodiment 3

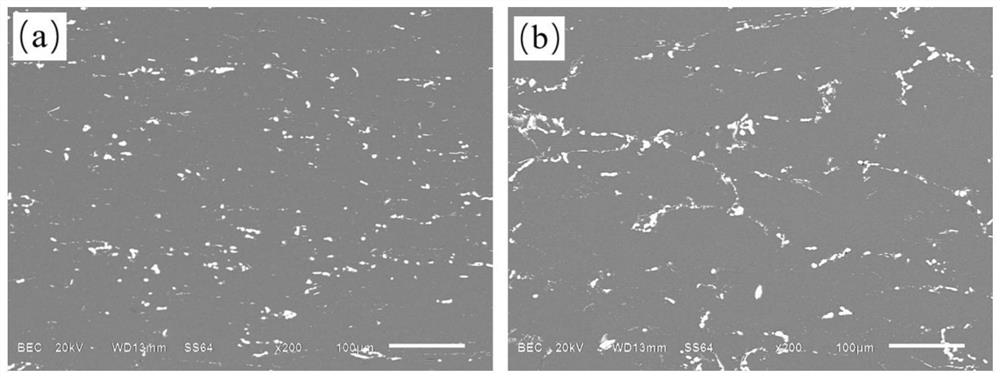

[0080] This embodiment provides a multi-stage homogenization annealing method for a 2219 aluminum alloy ingot with a diameter of 420 mm:

[0081](1) The first annealing: heat the 2219 aluminum alloy ingot to 185°C at the first heating rate of 60°C / h in a heat treatment furnace, and keep it for 4h;

[0082] (2) Second annealing: heat the cast ingot after the first annealing treatment to 455°C at the second heating rate of 90°C / h, and keep it warm for 8h;

[0083] (3) The third annealing: heat the ingot after the second annealing treatment to 520°C at the third heating rate of 95°C / h, and keep it warm for 18h;

[0084] (4) Cooling: Air-cool the ingot after the third annealing treatment to room temperature.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com