SiC-based tungsten disulfide ultraviolet-visible photoelectric detector and preparation method and application thereof

A photodetector, tungsten disulfide technology, applied in the field of ultraviolet-visible detection, can solve the problems of reducing the photosensitive area of materials, prolonging the transmission distance of photogenerated carriers, reducing device sensitivity, specific detection rate and response time, etc., to achieve effective Conducive to commercial promotion, enhancing the performance of photoelectric detection, and promoting the effect of application development

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] 1. Preparation:

[0037] (1) cleaning n - SiC(11μm) / n + SiC (360 μm) substrate. Ultrasonic the substrate with acetone, isopropanol, and deionized water for 20 minutes; then pass in oxygen with a flow rate of 50 sccm, and the power of the plasma is 100 W, and generate ozone for cleaning for 5 minutes;

[0038] (2) According to 49% hydrofluoric acid (HF) aqueous solution: 40% ammonium fluoride (NH 4 F) Aqueous solution = 1:6 (volume ratio) mixed to configure a buffered oxide etchant (BOE) solution. Washed n from step 1 - SiC(11μm) / n + Put the SiC (360 μm) substrate into the buffered oxide etching solution (BOE) solution for 4 minutes to etch the oxide on the surface of the SiC substrate;

[0039] (3) Use electron beam evaporation equipment to evaporate the back electrode Ni-Ag to the substrate n + SiC (360μm) surface, and then spin-coated as a positive photoresist of the German ALLRESISTARP-5350 model on n - On the SiC (11μm) surface, set the speed of the homogeni...

Embodiment 2

[0046] The difference from embodiment 1 is that: the back electrode is Ti-Au; the symmetrical electrode is Au.

Embodiment 3

[0048] The difference from Example 1 is that: the back electrode is Cr—Au.

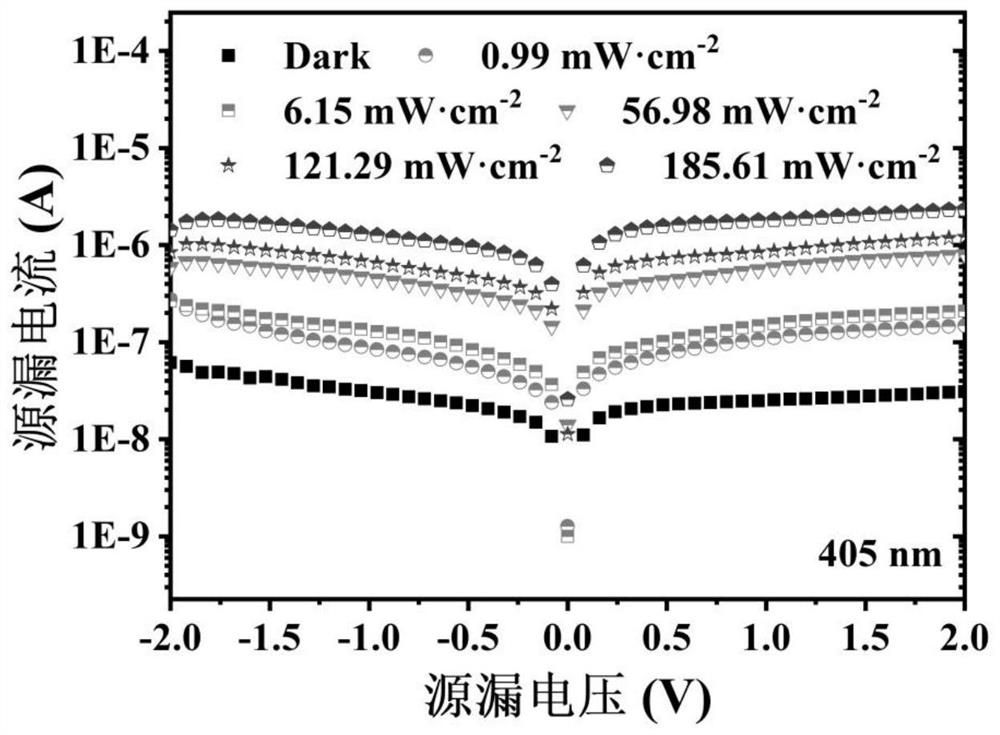

[0049] The present invention combines WS for the first time 2 n transferred to the evaporated symmetric electrode - SiC(11μm) / n + On SiC (360μm) substrates, the Fermi level pinning effect at the metal-semiconductor interface is weakened, and SiC and WS are synergistically exerted 2 Both UV-Vis absorption properties. Realized highly sensitive ultraviolet-visible detection function under 405nm laser irradiation (photosensitivity up to 60A / W, specific detection rate up to 4.94×10 11 Jones, external quantum efficiency 238%). The SiC-based tungsten disulfide ultraviolet photodetector of the present invention has a larger optical switch ratio (10 4 ), fast photoresponse (20~40ms), high sensitivity (R up to 60A / W, specific detection rate up to 5×10 11 Jones, with an external quantum efficiency of 238%), and has a bottom-gate regulated WS 2 specialty.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| external quantum efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com