Efficient pretreatment method for refractory metallurgical ore

A pretreatment and ore technology, applied in the field of metallurgy, can solve problems such as long process flow, heavy pollution, and large equipment investment, and achieve obvious economic and social benefits, reduce production costs, and reduce environmental pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

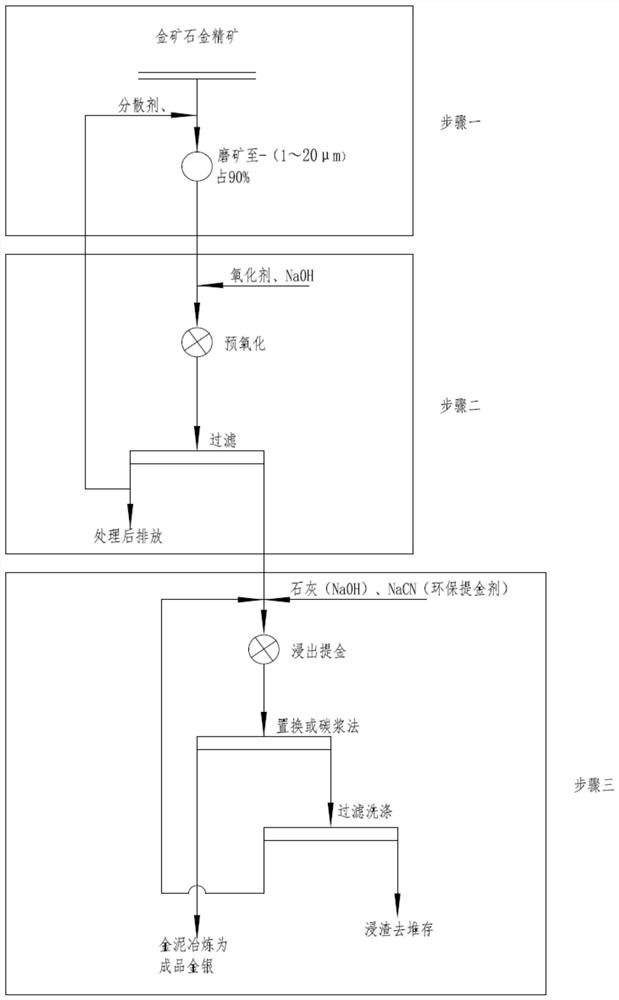

Method used

Image

Examples

Embodiment 1

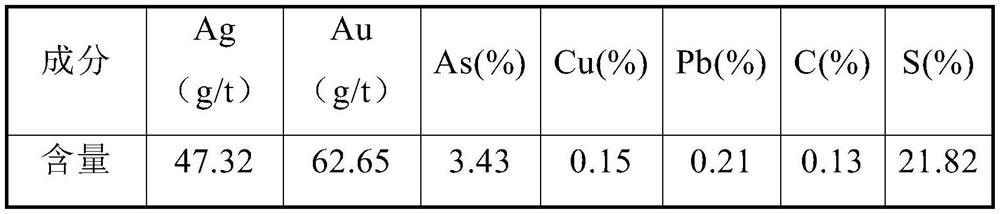

[0071] Treat 1 ton of gold concentrate from a mine in Gansu, and its chemical composition is shown in the table below:

[0072]

[0073] The gold leaching rate of direct cyanidation treatment of the gold concentrate is 45%, and the leaching rate of gold cyanide after roasting is 80%; the sales price is relatively low, and the economic benefit is relatively poor.

[0074] Step 1: first add water to the raw material to form a slurry with a solid-to-liquid mass ratio of 1:1.5, add sodium hexametaphosphate 10kg / t, finely grind to -5 μm to account for 90% (mass ratio), and enter step 2;

[0075] Step 2: Dilute the pulp from step 1 with water until the mass ratio of solid to liquid is 1:3, add 5kg / t of 30% hydrogen peroxide, 8kg / t of 99% industrial caustic soda, and carry out oxidation leaching for 6h. After the leaching is completed, part of the liquid obtained by filtering the slurry is returned to step 1 for slurry adjustment, and the other part is discharged after being neutr...

example 2

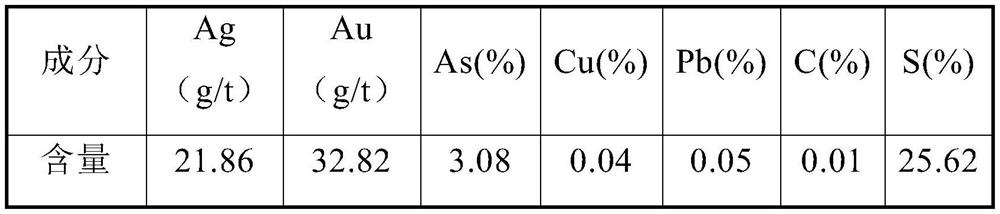

[0078] Processing 100kg of gold concentrate from a mine in Kyrgyzstan, its chemical composition is shown in the following table:

[0079]

[0080] The direct cyanidation treatment gold leaching rate of the gold concentrate is 27%, and the gold cyanide leaching rate after roasting is 78%; the sales price gold valuation coefficient is 70%, and the economic benefit is relatively poor.

[0081] Step 1: first add water to the raw material to form a slurry with a solid-to-liquid mass ratio of 1:1.5, add sodium hexametaphosphate 10kg / t, finely grind to -5 μm to account for 90% (mass ratio), and enter step 2;

[0082] Step 2: Dilute the pulp from step 1 with water to a solid-to-liquid mass ratio of 1:3, add ozone 12kg / t, 99% industrial caustic soda 15kg / t, and carry out oxidation leaching at normal temperature and pressure for 6 hours. After the leaching is completed, part of the liquid obtained by filtering the slurry is returned to step 1 for slurry adjustment, and the other part...

example 3

[0085] Processing 100kg of gold concentrate from a mine in Peru, its chemical composition is shown in the table below:

[0086]

[0087] The gold leaching rate of direct cyanidation treatment of the gold concentrate is 21%, and the gold leaching rate of cyanide after roasting in the smelter is 62%.

[0088] Step 1: first add water to the raw material to make a slurry with a solid-to-liquid mass ratio of 1:1.5, add sodium hexametaphosphate 15kg / t, finely grind to -2.5μm to account for 90% (mass ratio), and enter step 2;

[0089] Step 2: Dilute the pulp from step 1 with water to a solid-to-liquid mass ratio of 1:3, add ozone 21kg / t, 99% industrial caustic soda 5kg / t, and carry out oxidation leaching at normal temperature and pressure for 12 hours. After the leaching is completed, part of the liquid obtained by filtering the slurry is returned to step 1 for slurry adjustment, and the other part is discharged after being neutralized. The solid obtained after filtration was car...

PUM

| Property | Measurement | Unit |

|---|---|---|

| oxidation rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com