Preparation of a highly active and extremely low loading ruthenium catalyst ru@zif-8 and its application in catalytic hydrogenation

A ruthenium catalyst, catalytic hydrogenation technology, applied in the preparation of organic compounds, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc., can solve low activity, high loading capacity, poor stability, etc. problems, achieve good application prospects, simple preparation, and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

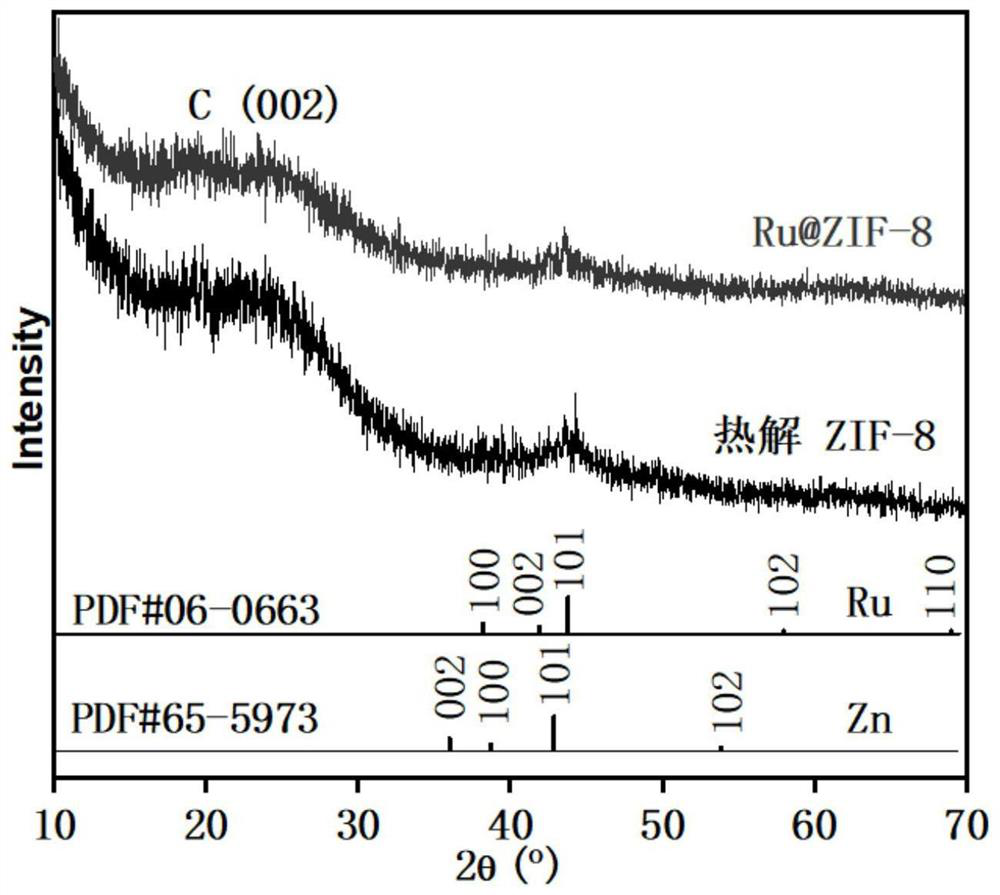

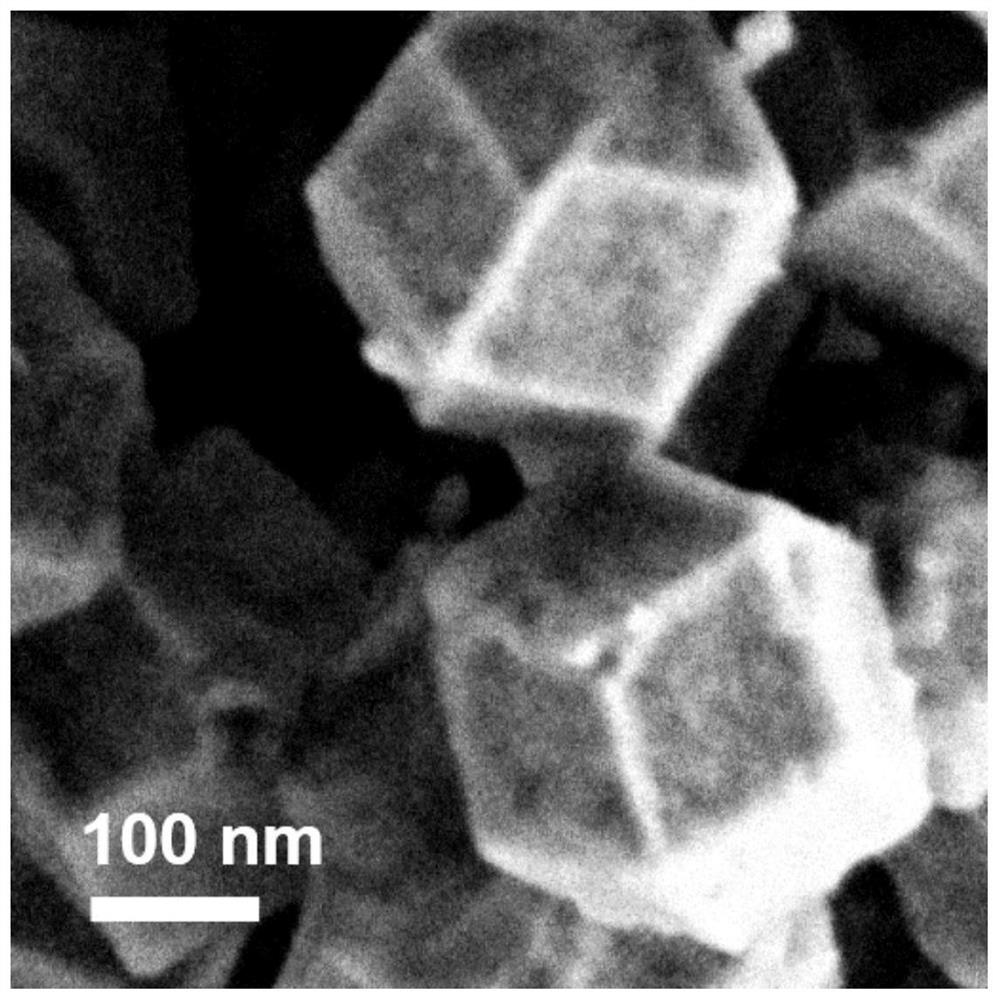

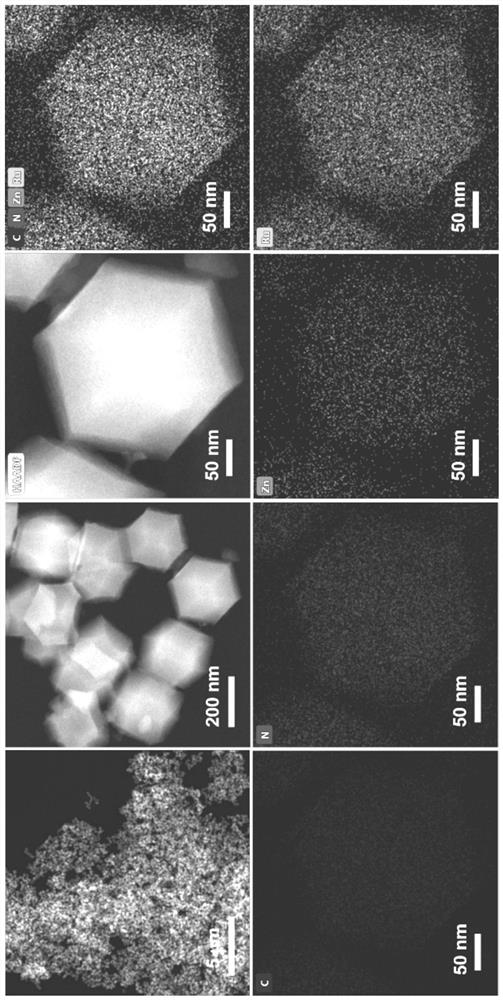

[0024] Embodiment 1: Preparation of Ru@ZIF-8 catalyst

[0025] 0.3g ruthenium acetylacetonate (Ru(acac) 3 ) and 5g zinc nitrate hexahydrate (Zn(NO 3 ) 2 ·6H 2 O) The precursor was dissolved in 50 mL of methanol to obtain solution A. 10 g of 2-methylimidazole was dissolved in 60 mL of methanol to obtain solution B, and solution B was added to the above precursor solution A under vigorous stirring. Then, the mixed solution was stirred at room temperature for 24 h. The product obtained was centrifuged and washed with methanol until the solution was colorless. The solid product was dried under vacuum at 80 °C overnight and labeled as Ru(acac) 3 @ZIF-8. Subsequently, the prepared Ru(acac) 3 @ZIF-8 is placed in a tube furnace and heated to 900°C at a rate of 5°C / min. In nitrogen (N 2 ) atmosphere at 900°C for 3h, the tube furnace was naturally cooled to room temperature. The resulting powder, labeled as Ru@ZIF-8, was directly used as a catalyst without further treatment. ...

Embodiment 2

[0040] Embodiment 2: the catalytic reaction of benzyl phenyl ether (BPE)

[0041] (1) Put 50mg of the reaction substrate benzyl phenyl ether, 10mg of the catalyst Ru@ZIF-8 and 10mL of isopropanol into a 100mL stainless steel autoclave, seal it and pass in hydrogen to remove the residual air in the reactor;

[0042] (2) Continuously feed hydrogen or argon at room temperature to pressurize the reactor to 1MPa, then raise the temperature to the required reaction temperature, and stir the reaction for 2h at a vigorous stirring speed of 800rpm;

[0043](3) After the reaction, the reaction system was naturally cooled to room temperature and the pressure was released, the catalyst was removed by filtration, and the obtained organic phase was analyzed by GC-MS and GC.

[0044] The catalyst that comparative example 1-2 makes is carried out the catalytic reaction of benzyl phenyl ether respectively, and reaction condition is the same as embodiment 2, and product is analyzed simultaneous...

Embodiment 3

[0051] Example 3: C-O bond cleavage reactions of other lignin model compounds

[0052] (1) Put 50mg of reactants, 10mg of catalyst Ru@ZIF-8 and 10mL of isopropanol into a 100mL stainless steel autoclave, seal it and pass in hydrogen to remove the residual air in the reactor;

[0053] (2) Continue to feed hydrogen at room temperature to pressurize the reactor to 1MPa, then stir and react at a certain temperature for 2-7h, and the stirring speed is 800rpm;

[0054] (3) After the reaction, the reaction system was naturally cooled to room temperature and the pressure was released, the catalyst was removed by filtration, and the organic phase obtained was analyzed by GC-MS and GC. The results are shown in Table 3.

[0055] Table 3 C-O bond cleavage of different lignin model compounds on Ru@ZIF-8 catalyst

[0056]

[0057] Reaction conditions: (a) 190°C, 2h, (b) 230°C, 5h, (c) 250°C, 7h.

[0058] It can be seen from Table 3 that the catalyst Ru@ZIF-8 prepared by the present inv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com