Tetragonal-phase nano-composite zirconia powder and preparation method thereof and sintered body

A nano-composite, zirconia powder technology, applied in the field of ceramic materials, can solve the problems of insufficient flexibility of chemical co-precipitation method, poor color repeatability, and difficulty in changing production lines.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-5

[0082] Example 1-5 (i.e. S1-5) prepares tetragonal phase nanocomposite zirconia powder

Embodiment 1

[0083] Embodiment 1 (ie S1)

[0084] (1) Co-precipitation

[0085] Weigh zirconium oxychloride octahydrate ZrOCl respectively 2 ·8H 2 O 161.12g, erbium nitrate pentahydrate Er (NO 3 ) 3 ·5H 2 O2.22g, cerium nitrate hexahydrate Ce(NO 3 ) 3 ·6H 2 O 27.41g, praseodymium nitrate hexahydrate Pr(NO 3 ) 3 ·6H 2 O 10.88g, dissolved in 500g deionized water to prepare a saline solution; then weigh ammonium bicarbonate NH 4 HCO 3 120g, dissolved in 700g deionized water to prepare lye; use a peristaltic pump to feed, and use the bottom feeding method at room temperature to carry out coprecipitation reaction, control the pH of the system during the coprecipitation reaction process to 4.5, and obtain the precursor slurry ;

[0086] (2) washing

[0087] The precursor slurry obtained in step (1) was suction-filtered and washed with deionized water at 50° C. to obtain a filter cake; the volume ratio of the deionized water used to the precursor slurry was 0.75:1,

[0088] (3) dr...

Embodiment 2-5

[0093] Embodiment 2-5 (being S2-5)

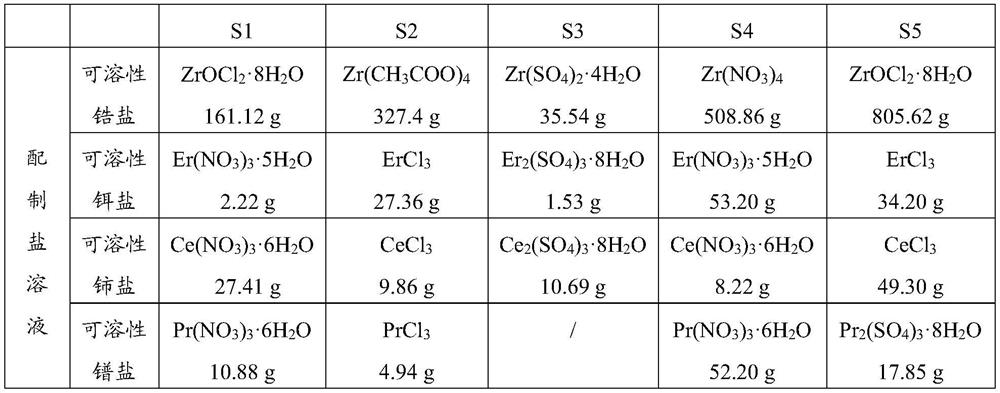

[0094] Tetragonal phase nanocomposite zirconia powder A2-5 was prepared according to the method of Example 1. The raw materials and amounts used are shown in Table 1, the conditions of each step are shown in Table 2, and the relevant parameters of the product are shown in Table 3.

[0095] Raw materials and dosage used in Table 1 S1-5

[0096]

[0097]

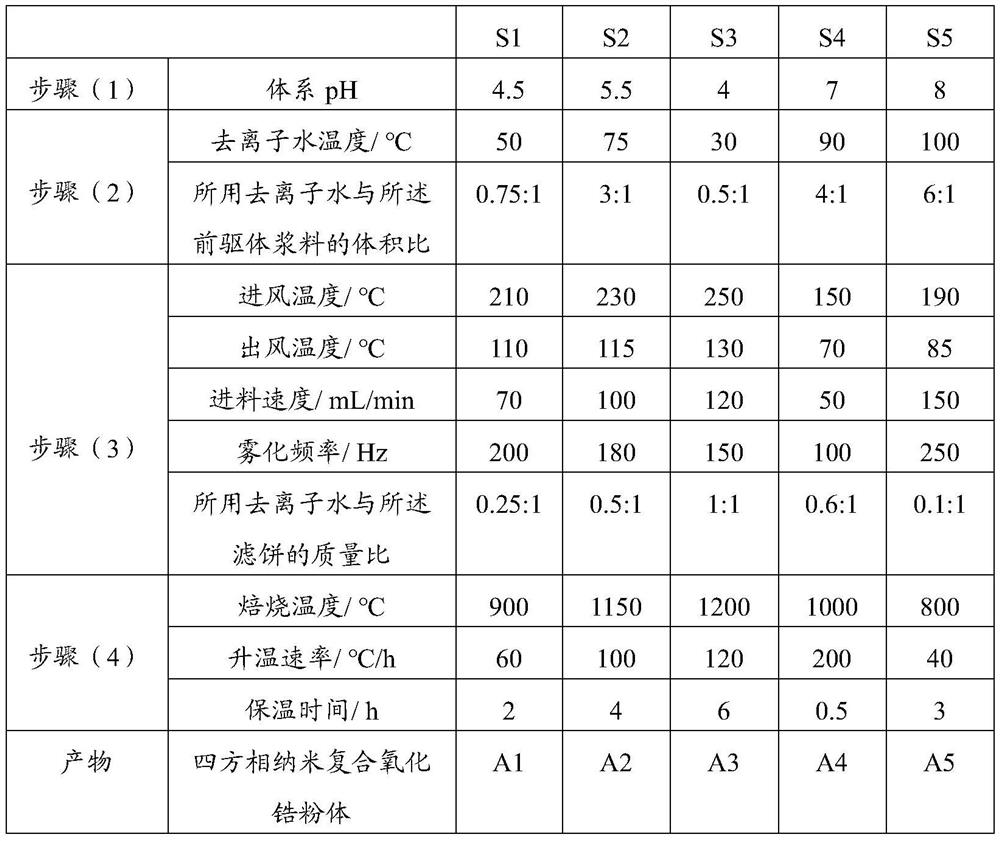

[0098] Conditions of each step in Table 2 S1-5

[0099]

[0100] Table 3 Relevant parameters of each product in S1-5

[0101]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com