Casting method of oil pressure casting

A technology of casting and hydraulic pressure, which is applied in the field of casting of hydraulic castings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

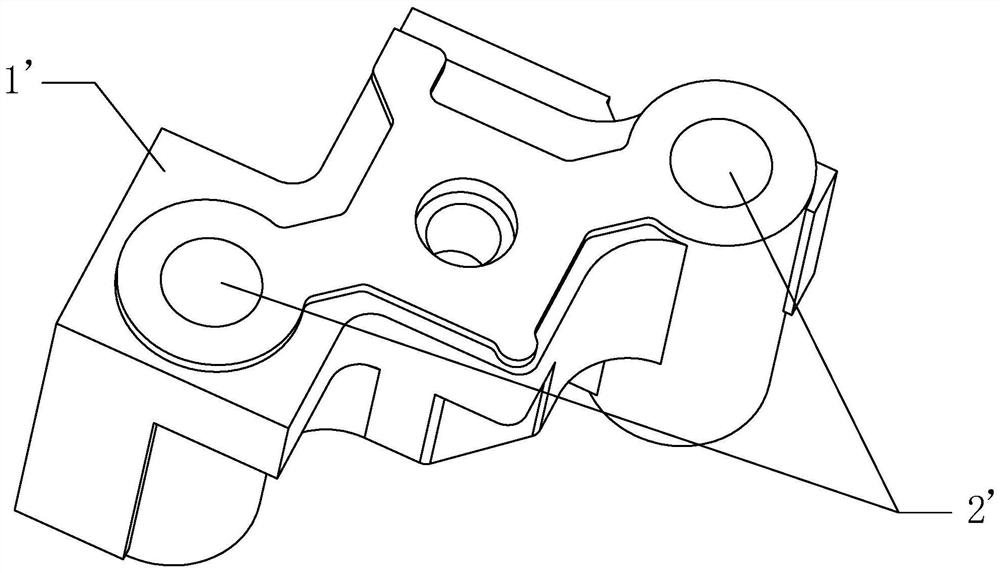

Image

Examples

Embodiment 1

[0068] (1) The raw material of following mass percentage is taken: 45% of pig iron, scrap steel 35%, return charge 20%, carburant: 1.0% of pig iron, scrap steel, return charge total amount;

[0069] (2) Put all the pig iron, steel scrap and returned charge into the smelting furnace, and then add the recarburizer with a total amount of 1.0% of the above formula; heat to melt the charge, and add FeSi75-C ferrosilicon and ferrosilicon after the charge is melted The amount of added iron is 0.8% of the total mass of pig iron, scrap steel and returned materials to obtain the original molten iron, and the original molten iron is continued to be heated to 1490 °C; the composition and mass percentage of the obtained original molten iron are C 3.58%, Si 1.45% , Mn 0.20%, P 0.025%, S 0.019%, and the rest is iron;

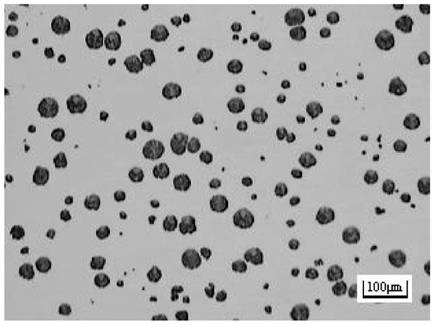

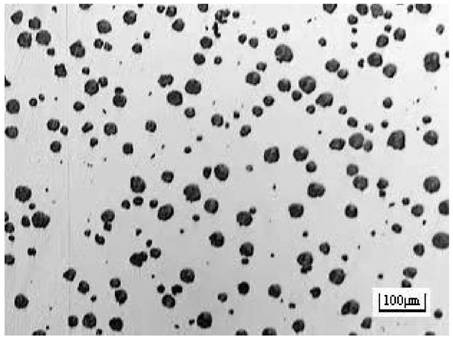

[0070] (3) Spheroidization: The spheroidization is carried out by the flushing method. The spheroidizing agent on one side of the spheroidizing bag is first added and compacte...

Embodiment 2

[0083] (1) The raw materials of the following mass percentages are taken by weighing: 50% of pig iron, 35% of steel scrap, 15% of recycled material, recarburizer: 1.1% of the total amount of pig iron, scrap steel, and recycled material;

[0084] (2) Put all the pig iron, scrap steel, and returned charge into the smelting furnace, and then add a carburant with a total formula of 1.1%; heat to melt the charge, and add FeSi75-C ferrosilicon and ferrosilicon after the charge is melted The amount of addition is 1.0% of the total mass of pig iron, scrap steel and recycled materials to obtain the original molten iron, and the original molten iron is continued to be heated to 1480 ° C; the composition and mass percentage of the obtained original molten iron are C 3.60%, Si 1.50%, Mn 0.18%, P 0.021%, S 0.018%, the rest is iron;

[0085] (3) The spheroidization is carried out by the flushing method. The spheroidizing dam on the side of the spheroidizing bag is firstly added with a spher...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com