Alloy powder for laser cladding repair of mining hydraulic stand column middle cylinder and repair method

A hydraulic column, laser cladding technology, applied in the direction of metal material coating process, coating, etc., can solve the problems of surface pitting, short corrosion life, alloy coating pitting, etc., to refine grains, improve production Effect of temperature and toughness increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0076]An alloy powder for laser cladding and repairing the middle cylinder of a mining hydraulic column, including the powder of the following components:

[0077] Cr: 16.6wt%;

[0078] Ni: 1.75wt%;

[0079] Co: 1.75wt%;

[0080] Mo: 1.0wt%;

[0081] Mn: 0.2wt%;

[0082] Nb: 0.15wt%;

[0083] C: 0.10wt%;

[0084] N: 0.10wt%;

[0085] Ce: 0.045wt%;

[0086] B: 0.76wt%;

[0087] Si: 1.0wt%;

[0088] Fe is the balance.

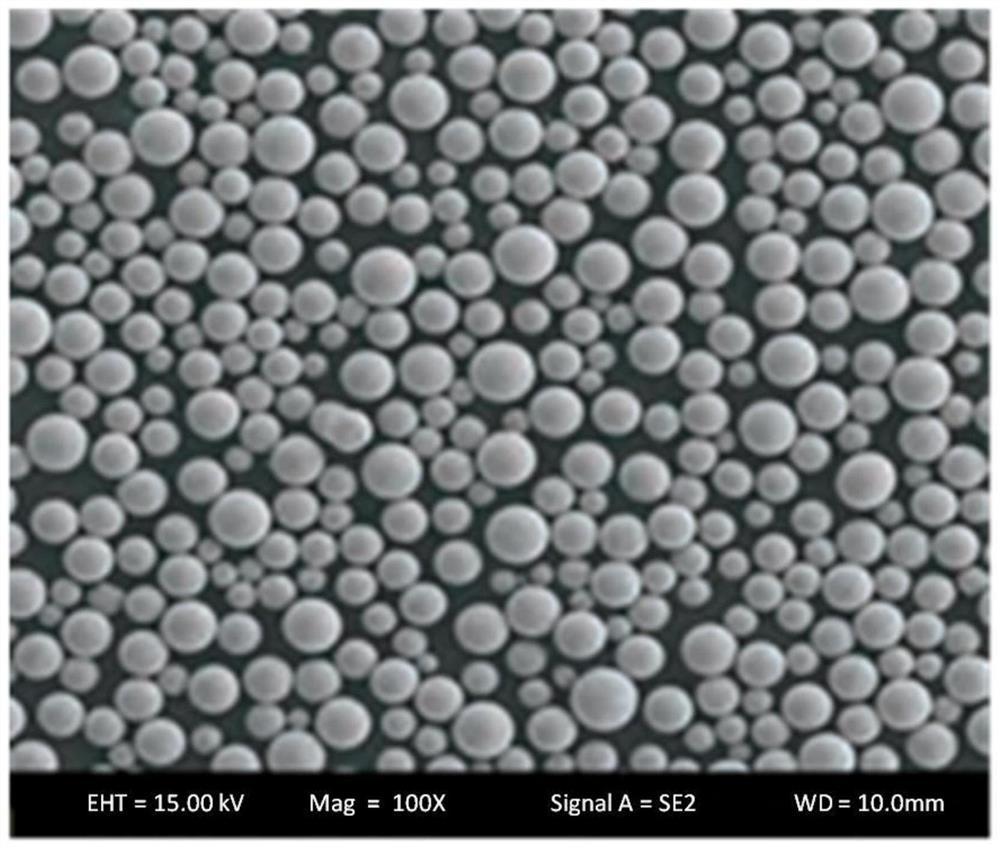

[0089] The above-mentioned alloy powder for laser cladding and repairing the middle cylinder of mining hydraulic column is prepared by pre-mixing and then using nitrogen atomization powder making method. The particle size distribution of the prepared powder is between 120 and 260 mesh. figure 1 It is the scanning electron microscope picture of the alloy powder. It can be seen that the sphericity is good in the picture, which can be used for laser cladding repair.

[0090] A laser cladding repair method for the middle cylinder of a mine hydraulic column...

Embodiment 2

[0096] An alloy powder for laser cladding and repairing the middle cylinder of a mining hydraulic column, including the powder of the following components:

[0097] Cr: 15.6wt%;

[0098] Ni: 1.65wt%;

[0099] Co: 1.65wt%;

[0100] Mo: 0.9wt%;

[0101] Mn: 0.3wt%;

[0102] Nb: 0.12wt%;

[0103] C: 0.09wt%;

[0104] N: 0.11wt%;

[0105] Ce: 0.035wt%;

[0106] B: 0.68wt%;

[0107] Si: 0.9wt%;

[0108] Fe is the balance.

[0109] The above-mentioned alloy powder for laser cladding and repairing the middle cylinder of mining hydraulic column is prepared by pre-mixing and then using nitrogen atomization powder making method, and the particle size distribution of the prepared powder is between 120 and 260 mesh.

[0110] A laser cladding repair method for the middle cylinder of a mine hydraulic column, based on the alloy powder for laser cladding repair of the mine hydraulic column middle cylinder, comprising the following steps:

[0111] 1) Remove the oil and impurities on...

Embodiment 3

[0116] An alloy powder for laser cladding and repairing the middle cylinder of a mining hydraulic column, including the powder of the following components:

[0117] Cr: 15.0wt%;

[0118] Ni: 1.5wt%;

[0119] Co: 1.5wt%;

[0120] Mo: 0.8wt%;

[0121] Mn: 0.0wt%;

[0122] Nb: 0.1wt%;

[0123] C: 0.07wt%;

[0124] N: 0.06wt%;

[0125] Ce: 0.03wt%;

[0126] B: 0.6wt%;

[0127] Si: 0.8wt%;

[0128] Fe is the balance.

[0129] The above-mentioned alloy powder for laser cladding and repairing the middle cylinder of mining hydraulic column is prepared by pre-mixing and then using nitrogen atomization powder making method, and the particle size distribution of the prepared powder is between 120 and 260 mesh.

[0130] A laser cladding repair method for the middle cylinder of a mine hydraulic column, based on the alloy powder for laser cladding repair of the mine hydraulic column middle cylinder, comprising the following steps:

[0131] 1) Remove the oil and impurities on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com